Separator's Digest - GEA Westfalia Separator Group

Separator's Digest - GEA Westfalia Separator Group

Separator's Digest - GEA Westfalia Separator Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

30 Process <strong>Separator</strong>’s <strong>Digest</strong> 3 | 2008<br />

<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong><br />

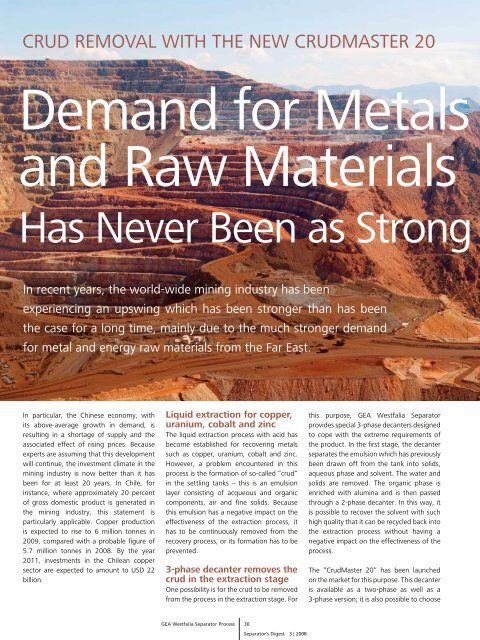

Crud removal with the new Crudmaster 20<br />

demand for metals<br />

and raw materials<br />

has never Been as strong<br />

in recent years, the world-wide mining industry has been<br />

experiencing an upswing which has been stronger than has been<br />

the case for a long time, mainly due to the much stronger demand<br />

for metal and energy raw materials from the Far east.<br />

in particular, the Chinese economy, with<br />

its above-average growth in demand, is<br />

resulting in a shortage of supply and the<br />

associated effect of rising prices. Because<br />

experts are assuming that this development<br />

will continue, the investment climate in the<br />

mining industry is now better than it has<br />

been for at least 20 years. in Chile, for<br />

instance, where approximately 20 percent<br />

of gross domestic product is generated in<br />

the mining industry, this statement is<br />

particularly applicable. Copper production<br />

is expected to rise to 6 million tonnes in<br />

2009, compared with a probable figure of<br />

5.7 million tonnes in 2008. By the year<br />

2011, investments in the Chilean copper<br />

sector are expected to amount to usd 22<br />

billion.<br />

Liquid extraction for copper,<br />

uranium, cobalt and zinc<br />

the liquid extraction process with acid has<br />

become established for recovering metals<br />

such as copper, uranium, cobalt and zinc.<br />

however, a problem encountered in this<br />

process is the formation of so-called “crud“<br />

in the settling tanks – this is an emulsion<br />

layer consisting of acqueous and organic<br />

components, air and fine solids. Because<br />

this emulsion has a negative impact on the<br />

effectiveness of the extraction process, it<br />

has to be continuously removed from the<br />

recovery process, or its formation has to be<br />

prevented.<br />

3-phase decanter removes the<br />

crud in the extraction stage<br />

one possibility is for the crud to be removed<br />

from the process in the extraction stage. For<br />

<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong> Process 30<br />

<strong>Separator</strong>’s <strong>Digest</strong> 3 | 2008<br />

this purpose, Gea westfalia separator<br />

provides special 3-phase decanters designed<br />

to cope with the extreme requirements of<br />

the product. in the first stage, the decanter<br />

separates the emulsion which has previously<br />

been drawn off from the tank into solids,<br />

aqueous phase and solvent. the water and<br />

solids are removed. the organic phase is<br />

enriched with alumina and is then passed<br />

through a 2-phase decanter. in this way, it<br />

is possible to recover the solvent with such<br />

high quality that it can be recycled back into<br />

the extraction process without having a<br />

negative impact on the effectiveness of the<br />

process.<br />

the “Crudmaster 20“ has been launched<br />

on the market for this purpose. this decanter<br />

is available as a two-phase as well as a<br />

3-phase version; it is also possible to choose