Health and safety in motor vehicle repair and associated industries

Health and safety in motor vehicle repair and associated industries

Health and safety in motor vehicle repair and associated industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

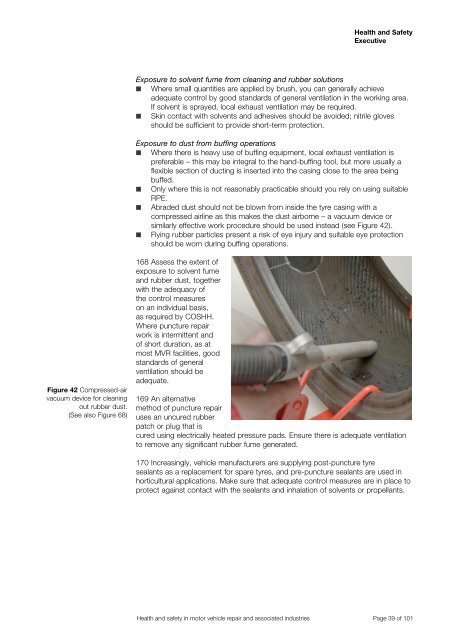

Figure 42 Compressed-air<br />

vacuum device for clean<strong>in</strong>g<br />

out rubber dust.<br />

(See also Figure 68)<br />

<strong>Health</strong> <strong>and</strong> Safety<br />

Executive<br />

Exposure to solvent fume from clean<strong>in</strong>g <strong>and</strong> rubber solutions<br />

n Where small quantities are applied by brush, you can generally achieve<br />

adequate control by good st<strong>and</strong>ards of general ventilation <strong>in</strong> the work<strong>in</strong>g area.<br />

If solvent is sprayed, local exhaust ventilation may be required.<br />

n Sk<strong>in</strong> contact with solvents <strong>and</strong> adhesives should be avoided; nitrile gloves<br />

should be sufficient to provide short-term protection.<br />

Exposure to dust from buff<strong>in</strong>g operations<br />

n Where there is heavy use of buff<strong>in</strong>g equipment, local exhaust ventilation is<br />

preferable – this may be <strong>in</strong>tegral to the h<strong>and</strong>-buff<strong>in</strong>g tool, but more usually a<br />

flexible section of duct<strong>in</strong>g is <strong>in</strong>serted <strong>in</strong>to the cas<strong>in</strong>g close to the area be<strong>in</strong>g<br />

buffed.<br />

n Only where this is not reasonably practicable should you rely on us<strong>in</strong>g suitable<br />

RPE.<br />

n Abraded dust should not be blown from <strong>in</strong>side the tyre cas<strong>in</strong>g with a<br />

compressed airl<strong>in</strong>e as this makes the dust airborne – a vacuum device or<br />

similarly effective work procedure should be used <strong>in</strong>stead (see Figure 42).<br />

n Fly<strong>in</strong>g rubber particles present a risk of eye <strong>in</strong>jury <strong>and</strong> suitable eye protection<br />

should be worn dur<strong>in</strong>g buff<strong>in</strong>g operations.<br />

168 Assess the extent of<br />

exposure to solvent fume<br />

<strong>and</strong> rubber dust, together<br />

with the adequacy of<br />

the control measures<br />

on an <strong>in</strong>dividual basis,<br />

as required by COSHH.<br />

Where puncture <strong>repair</strong><br />

work is <strong>in</strong>termittent <strong>and</strong><br />

of short duration, as at<br />

most MVR facilities, good<br />

st<strong>and</strong>ards of general<br />

ventilation should be<br />

adequate.<br />

169 An alternative<br />

method of puncture <strong>repair</strong><br />

uses an uncured rubber<br />

patch or plug that is<br />

cured us<strong>in</strong>g electrically heated pressure pads. Ensure there is adequate ventilation<br />

to remove any significant rubber fume generated.<br />

170 Increas<strong>in</strong>gly, <strong>vehicle</strong> manufacturers are supply<strong>in</strong>g post-puncture tyre<br />

sealants as a replacement for spare tyres, <strong>and</strong> pre-puncture sealants are used <strong>in</strong><br />

horticultural applications. Make sure that adequate control measures are <strong>in</strong> place to<br />

protect aga<strong>in</strong>st contact with the sealants <strong>and</strong> <strong>in</strong>halation of solvents or propellants.<br />

<strong>Health</strong> <strong>and</strong> <strong>safety</strong> <strong>in</strong> <strong>motor</strong> <strong>vehicle</strong> <strong>repair</strong> <strong>and</strong> <strong>associated</strong> <strong>in</strong>dustries Page 39 of 101