Health and safety in motor vehicle repair and associated industries

Health and safety in motor vehicle repair and associated industries

Health and safety in motor vehicle repair and associated industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

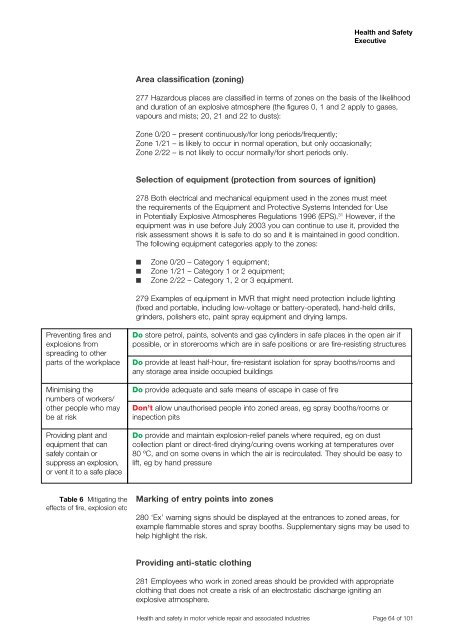

Prevent<strong>in</strong>g fires <strong>and</strong><br />

explosions from<br />

spread<strong>in</strong>g to other<br />

parts of the workplace<br />

M<strong>in</strong>imis<strong>in</strong>g the<br />

numbers of workers/<br />

other people who may<br />

be at risk<br />

Provid<strong>in</strong>g plant <strong>and</strong><br />

equipment that can<br />

safely conta<strong>in</strong> or<br />

suppress an explosion,<br />

or vent it to a safe place<br />

Table 6 Mitigat<strong>in</strong>g the<br />

effects of fire, explosion etc<br />

Area classification (zon<strong>in</strong>g)<br />

<strong>Health</strong> <strong>and</strong> Safety<br />

Executive<br />

277 Hazardous places are classified <strong>in</strong> terms of zones on the basis of the likelihood<br />

<strong>and</strong> duration of an explosive atmosphere (the figures 0, 1 <strong>and</strong> 2 apply to gases,<br />

vapours <strong>and</strong> mists; 20, 21 <strong>and</strong> 22 to dusts):<br />

Zone 0/20 – present cont<strong>in</strong>uously/for long periods/frequently;<br />

Zone 1/21 – is likely to occur <strong>in</strong> normal operation, but only occasionally;<br />

Zone 2/22 – is not likely to occur normally/for short periods only.<br />

Selection of equipment (protection from sources of ignition)<br />

278 Both electrical <strong>and</strong> mechanical equipment used <strong>in</strong> the zones must meet<br />

the requirements of the Equipment <strong>and</strong> Protective Systems Intended for Use<br />

<strong>in</strong> Potentially Explosive Atmospheres Regulations 1996 (EPS). 31 However, if the<br />

equipment was <strong>in</strong> use before July 2003 you can cont<strong>in</strong>ue to use it, provided the<br />

risk assessment shows it is safe to do so <strong>and</strong> it is ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong> good condition.<br />

The follow<strong>in</strong>g equipment categories apply to the zones:<br />

n<br />

n<br />

n<br />

Zone 0/20 – Category 1 equipment;<br />

Zone 1/21 – Category 1 or 2 equipment;<br />

Zone 2/22 – Category 1, 2 or 3 equipment.<br />

279 Examples of equipment <strong>in</strong> MVR that might need protection <strong>in</strong>clude light<strong>in</strong>g<br />

(fixed <strong>and</strong> portable, <strong>in</strong>clud<strong>in</strong>g low-voltage or battery-operated), h<strong>and</strong>-held drills,<br />

gr<strong>in</strong>ders, polishers etc, pa<strong>in</strong>t spray equipment <strong>and</strong> dry<strong>in</strong>g lamps.<br />

Do store petrol, pa<strong>in</strong>ts, solvents <strong>and</strong> gas cyl<strong>in</strong>ders <strong>in</strong> safe places <strong>in</strong> the open air if<br />

possible, or <strong>in</strong> storerooms which are <strong>in</strong> safe positions or are fire-resist<strong>in</strong>g structures<br />

Do provide at least half-hour, fire-resistant isolation for spray booths/rooms <strong>and</strong><br />

any storage area <strong>in</strong>side occupied build<strong>in</strong>gs<br />

Do provide adequate <strong>and</strong> safe means of escape <strong>in</strong> case of fire<br />

Don’t allow unauthorised people <strong>in</strong>to zoned areas, eg spray booths/rooms or<br />

<strong>in</strong>spection pits<br />

Do provide <strong>and</strong> ma<strong>in</strong>ta<strong>in</strong> explosion-relief panels where required, eg on dust<br />

collection plant or direct-fired dry<strong>in</strong>g/cur<strong>in</strong>g ovens work<strong>in</strong>g at temperatures over<br />

80 ºC, <strong>and</strong> on some ovens <strong>in</strong> which the air is recirculated. They should be easy to<br />

lift, eg by h<strong>and</strong> pressure<br />

Mark<strong>in</strong>g of entry po<strong>in</strong>ts <strong>in</strong>to zones<br />

280 ‘Ex’ warn<strong>in</strong>g signs should be displayed at the entrances to zoned areas, for<br />

example flammable stores <strong>and</strong> spray booths. Supplementary signs may be used to<br />

help highlight the risk.<br />

Provid<strong>in</strong>g anti-static cloth<strong>in</strong>g<br />

281 Employees who work <strong>in</strong> zoned areas should be provided with appropriate<br />

cloth<strong>in</strong>g that does not create a risk of an electrostatic discharge ignit<strong>in</strong>g an<br />

explosive atmosphere.<br />

<strong>Health</strong> <strong>and</strong> <strong>safety</strong> <strong>in</strong> <strong>motor</strong> <strong>vehicle</strong> <strong>repair</strong> <strong>and</strong> <strong>associated</strong> <strong>in</strong>dustries Page 64 of 101