Health and safety in motor vehicle repair and associated industries

Health and safety in motor vehicle repair and associated industries

Health and safety in motor vehicle repair and associated industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

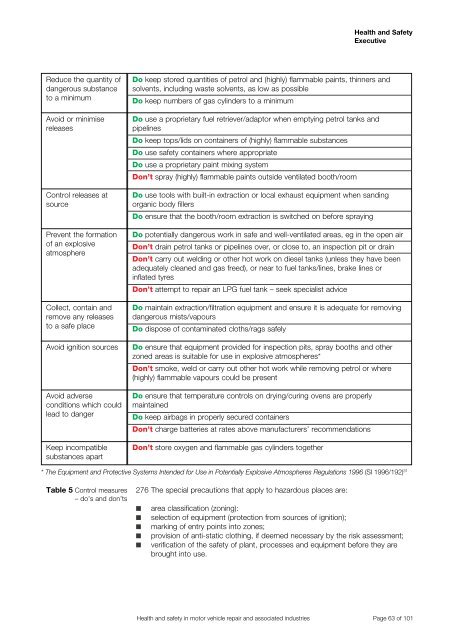

Reduce the quantity of<br />

dangerous substance<br />

to a m<strong>in</strong>imum<br />

Avoid or m<strong>in</strong>imise<br />

releases<br />

Control releases at<br />

source<br />

Prevent the formation<br />

of an explosive<br />

atmosphere<br />

Collect, conta<strong>in</strong> <strong>and</strong><br />

remove any releases<br />

to a safe place<br />

Avoid ignition sources<br />

Avoid adverse<br />

conditions which could<br />

lead to danger<br />

Keep <strong>in</strong>compatible<br />

substances apart<br />

Table 5 Control measures<br />

– do’s <strong>and</strong> don’ts<br />

276 The special precautions that apply to hazardous places are:<br />

n<br />

n<br />

n<br />

n<br />

n<br />

<strong>Health</strong> <strong>and</strong> Safety<br />

Executive<br />

Do keep stored quantities of petrol <strong>and</strong> (highly) flammable pa<strong>in</strong>ts, th<strong>in</strong>ners <strong>and</strong><br />

solvents, <strong>in</strong>clud<strong>in</strong>g waste solvents, as low as possible<br />

Do keep numbers of gas cyl<strong>in</strong>ders to a m<strong>in</strong>imum<br />

Do use a proprietary fuel retriever/adaptor when empty<strong>in</strong>g petrol tanks <strong>and</strong><br />

pipel<strong>in</strong>es<br />

Do keep tops/lids on conta<strong>in</strong>ers of (highly) flammable substances<br />

Do use <strong>safety</strong> conta<strong>in</strong>ers where appropriate<br />

Do use a proprietary pa<strong>in</strong>t mix<strong>in</strong>g system<br />

Don’t spray (highly) flammable pa<strong>in</strong>ts outside ventilated booth/room<br />

Do use tools with built-<strong>in</strong> extraction or local exhaust equipment when s<strong>and</strong><strong>in</strong>g<br />

organic body fillers<br />

Do ensure that the booth/room extraction is switched on before spray<strong>in</strong>g<br />

Do potentially dangerous work <strong>in</strong> safe <strong>and</strong> well-ventilated areas, eg <strong>in</strong> the open air<br />

Don’t dra<strong>in</strong> petrol tanks or pipel<strong>in</strong>es over, or close to, an <strong>in</strong>spection pit or dra<strong>in</strong><br />

Don’t carry out weld<strong>in</strong>g or other hot work on diesel tanks (unless they have been<br />

adequately cleaned <strong>and</strong> gas freed), or near to fuel tanks/l<strong>in</strong>es, brake l<strong>in</strong>es or<br />

<strong>in</strong>flated tyres<br />

Don’t attempt to <strong>repair</strong> an LPG fuel tank – seek specialist advice<br />

Do ma<strong>in</strong>ta<strong>in</strong> extraction/filtration equipment <strong>and</strong> ensure it is adequate for remov<strong>in</strong>g<br />

dangerous mists/vapours<br />

Do dispose of contam<strong>in</strong>ated cloths/rags safely<br />

Do ensure that equipment provided for <strong>in</strong>spection pits, spray booths <strong>and</strong> other<br />

zoned areas is suitable for use <strong>in</strong> explosive atmospheres*<br />

Don’t smoke, weld or carry out other hot work while remov<strong>in</strong>g petrol or where<br />

(highly) flammable vapours could be present<br />

Do ensure that temperature controls on dry<strong>in</strong>g/cur<strong>in</strong>g ovens are properly<br />

ma<strong>in</strong>ta<strong>in</strong>ed<br />

Do keep airbags <strong>in</strong> properly secured conta<strong>in</strong>ers<br />

Don’t charge batteries at rates above manufacturers’ recommendations<br />

Don’t store oxygen <strong>and</strong> flammable gas cyl<strong>in</strong>ders together<br />

* The Equipment <strong>and</strong> Protective Systems Intended for Use <strong>in</strong> Potentially Explosive Atmospheres Regulations 1996 (SI 1996/192) 31<br />

area classification (zon<strong>in</strong>g):<br />

selection of equipment (protection from sources of ignition);<br />

mark<strong>in</strong>g of entry po<strong>in</strong>ts <strong>in</strong>to zones;<br />

provision of anti-static cloth<strong>in</strong>g, if deemed necessary by the risk assessment;<br />

verification of the <strong>safety</strong> of plant, processes <strong>and</strong> equipment before they are<br />

brought <strong>in</strong>to use.<br />

<strong>Health</strong> <strong>and</strong> <strong>safety</strong> <strong>in</strong> <strong>motor</strong> <strong>vehicle</strong> <strong>repair</strong> <strong>and</strong> <strong>associated</strong> <strong>in</strong>dustries Page 63 of 101