food Marketing - Technology 6/2022

food Marketing & Technology is the international magazine for executives and specialists in the food industry.

food Marketing & Technology is the international magazine for executives and specialists in the food industry.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Packaging<br />

Integrated Controllers, the conveyors,<br />

and also built the control cabinet. The<br />

Vipers are articulated, 6-axis robots<br />

with a maximum payload of 5kg. The<br />

OMRON NJ501-R Robotics Integrated<br />

Controller has been developed for<br />

applications that require high-speed<br />

processing for machine control,<br />

safety, reliability and maintainability.<br />

It enables users to increase the speed<br />

and accuracy of production, whilst<br />

reducing maintenance and time-tomarket.<br />

Key benefits of the new robotics<br />

approach<br />

Guy Beyens continues: “The user<br />

interface for the new system is very<br />

easy and user-friendly. For example,<br />

you can make minute adjustments<br />

in the movement using the touch<br />

panel, that were not possible with<br />

other systems. Thanks to the Robotics<br />

Integrated Controller, the position<br />

of the robot is updated in real time,<br />

which is especially important in the<br />

gluing process. The solution makes<br />

it possible to react to environmental<br />

factors and adjust as needed, enabling<br />

the in-house technicians and operators<br />

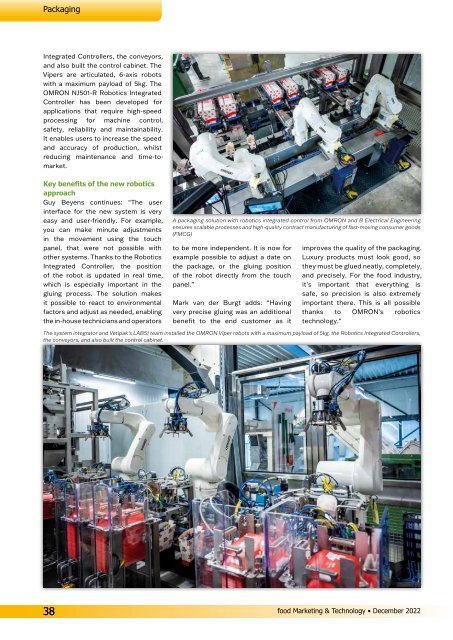

A packaging solution with robotics integrated control from OMRON and B Electrical Engineering<br />

ensures scalable processes and high-quality contract manufacturing of fast-moving consumer goods<br />

(FMCG)<br />

to be more independent. It is now for<br />

example possible to adjust a date on<br />

the package, or the gluing position<br />

of the robot directly from the touch<br />

panel.”<br />

Mark van der Burgt adds: “Having<br />

very precise gluing was an additional<br />

benefit to the end customer as it<br />

improves the quality of the packaging.<br />

Luxury products must look good, so<br />

they must be glued neatly, completely,<br />

and precisely. For the <strong>food</strong> industry,<br />

it’s important that everything is<br />

safe, so precision is also extremely<br />

important there. This is all possible<br />

thanks to OMRON’s robotics<br />

technology.“<br />

The system integrator and Vetipak’s LAB51 team installed the OMRON Viper robots with a maximum payload of 5kg, the Robotics Integrated Controllers,<br />

the conveyors, and also built the control cabinet.<br />

38<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • December <strong>2022</strong>