National Hardwood Magazine - March 2011

Check out the National Hardwood Magazine's latest issue and stay up-to-date on all the trends, news, and industry info you need.

Check out the National Hardwood Magazine's latest issue and stay up-to-date on all the trends, news, and industry info you need.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>March</strong> <strong>2011</strong><br />

ENOUGH WAITING. IT’S TIME TO START<br />

YOUR OWN STIMULUS PROGRAM WITH<br />

NORTHWEST HARDWOODS BRAND<br />

LUMBER. GET MORE OF WHAT YOU<br />

NEED IN EVERY UNIT DUE TO OUR<br />

GRADED FOR YIELD ®<br />

PROCESS.<br />

wy.com/hardwoods

And We Think The World Of You Too!<br />

For more than 40 years, the<br />

Walter M. Fields Lumber Company<br />

has built a reputation for producing<br />

only the finest textured White Ash<br />

for users worldwide. We have more<br />

than 300,000 board feet of dry kilns,<br />

200,000 board feet of air drying buildings,<br />

and a 2 million board foot dry<br />

storage building. As well as on-site<br />

rail, truck and container shipping.<br />

And we’re located in Memphis,<br />

Tennessee, the hardwood capital of<br />

the world. A lot of wood. A lot of<br />

history. A dedication to meeting your<br />

most exacting standards. When it<br />

comes to ash, the world comes to<br />

Fields Lumber. Call us at 901/948-7751<br />

or visit www.fieldslumber.com<br />

Walter M. Fields Lumber Company<br />

Southern & Appalachian <strong>Hardwood</strong>s<br />

Quality • Service • Dependability<br />

P .O. Box 13231 • 2401 Harbor Avenue • Presidents Island • Memphis, TN 38113<br />

Phone: 901/948-7751 • Fax: 901/948-7752 • Website: www.fieldslumber.com

In today’s complex world<br />

at least one thing is plain and simple.<br />

At Cersosimo we provide you with the<br />

largest and most consistent supply of<br />

quality hardwood—from the heart of<br />

New England forests. And we’ve been<br />

doing it for over 55 years. You’ve come<br />

to count on us to be there and deliver<br />

the best—and do it consistently.<br />

It’s straight talk from folks who are<br />

easy to talk to, who know the business<br />

inside and out—and whose integrity<br />

is as solid as the lumber we provide.<br />

www.cersosimolumber.com

PUT SOME<br />

WIND<br />

BEHIND YOUR<br />

RECOVERY<br />

Dry kiln owners worldwide are<br />

stimulating their profits with<br />

Smithco propellers. Smithco's<br />

4, 6, 8 and 12 bladed propellers,<br />

ranging in size from 30" to 84,"<br />

can be configured for maximum<br />

air flow with lowest power<br />

consumption. Our reversible,<br />

adjustable blade propellers allow<br />

you to optimize the cost/benefit<br />

ratio for your kiln application.<br />

100% reversibility for uniform drying<br />

cycles and maximum through-put<br />

Permanent mold S-profile aluminum<br />

blades and hubs, heat-treated for<br />

longest life in kiln environment<br />

Precision hubs with stainless steel<br />

hardware, balanced for low-noise,<br />

vibration-free operation<br />

Fast, accurate blade pitch angle<br />

setting with Smithco’s exclusive<br />

Degree Gauge<br />

So choose the propeller with<br />

a proven return — Smithco!<br />

SMITHCO<br />

MANUFACTURING, INC.<br />

7911 N.E. 33rd Dr. Portland, OR 97211<br />

503-295-6590 Fax 503-295-6822<br />

800-764-8456 U.S.<br />

e-mail: sales@smithcomfg.com<br />

www.smithcomfg.com<br />

Contents:<br />

Features:<br />

Lebanon Oak Flooring: Over A Century Of Success, And Still Going Strong ...18<br />

Neff Lumber – Manufacturing Quality Appalachian <strong>Hardwood</strong>s .........................20<br />

Winter Wisconsin Meeting Enjoyed By LSLA Attendees......................................22<br />

NASCAR Spotter Offers Report To Appalachian Group .......................................24<br />

Dwight Lewis/Lewis Lumber Co-Host First Penn-York Meeting For <strong>2011</strong> ..........26<br />

International Builders Show Convenes In Orlando...............................................28<br />

SURFACESʼ Attendees Gain Guidance On Meeting Goals...................................32<br />

Departments:<br />

<strong>Hardwood</strong> Calendar.......................................................................................................4<br />

U.S.A. Trends .................................................................................................................6<br />

Canadian Trends............................................................................................................7<br />

Eye On Technology .......................................................................................................8<br />

NHLA News................................................................................................................10<br />

HMA & Solid <strong>Hardwood</strong> Promotion.........................................................................12<br />

AHEC Update ............................................................................................................14<br />

WCMA Component Trends.......................................................................................16<br />

Whoʼs Who ................................................................................................................44<br />

Trade Talk ..................................................................................................................48<br />

Classified Opportunities ..........................................................................................58<br />

Advertisers Index......................................................................................................60<br />

The publisher reserves the right to accept or reject<br />

editorial content and Ads at the staff’s discretion.<br />

2 <strong>Hardwood</strong>s...The All-Purpose Material

<strong>March</strong>, <strong>2011</strong> Vol. 85, No. 2<br />

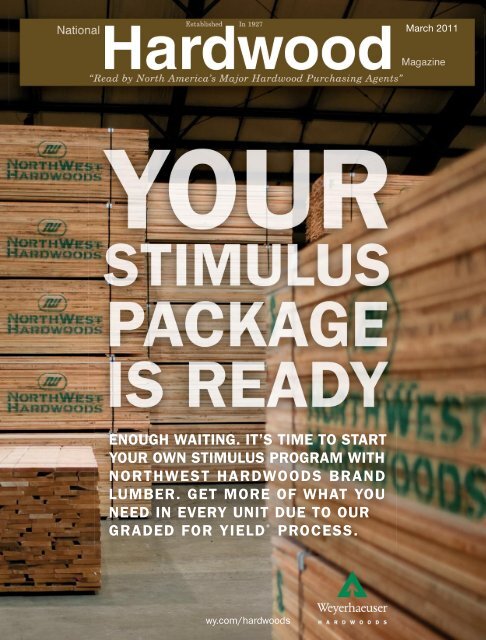

The Cover<br />

Weyerhaeuser <strong>Hardwood</strong>s provides<br />

the furniture, cabinet and millwork<br />

industries with a single source for a<br />

broad range of products. The company<br />

is a manufacturer and global supplier<br />

of a wide range of hardwood lumber<br />

including: alder, hard and soft maple,<br />

cherry, red and white oak, hickory,<br />

walnut, yellow poplar and European<br />

beech.<br />

Also available are hardwood and<br />

softwood plywood and wood components.<br />

For more information call 866-870-3040, email – hardwoods@weyerhaeuser.com<br />

or visit the company website:<br />

www.wy.com/hardwoods.<br />

G.F. <strong>Hardwood</strong>s, Inc.<br />

“A Company You Can Depend On”<br />

Species<br />

9880 Clay County Hwy.<br />

Moss, TN 38575-6332<br />

Phone: 1-800-844-3944<br />

Fax 1-931-258-3517<br />

Kevin Sweezy<br />

kevin@gfhardwoods.com<br />

Quality Appalachian<br />

<strong>Hardwood</strong> Lumber<br />

Services<br />

Facilities<br />

• Red Oak<br />

• Poplar<br />

• Hard Maple<br />

• White Oak<br />

• Ash<br />

• Cherry<br />

• Own Trucks<br />

• Cut 4/4<br />

through 8/4<br />

• Grade After Kiln<br />

Drying<br />

• Computer Tally<br />

• 5 Length<br />

Separations<br />

• 800,000 B.F.<br />

Kiln Capacity<br />

• 500,000 B.F.<br />

Predryer<br />

Capacity<br />

• Yates American<br />

Planer<br />

Founded in 1927 by:<br />

O.L. MILLER - 1894 - 1963<br />

Publisher: PAUL J. MILLER - 1963 - 2010<br />

The <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> is the product of a company and its affiliates that have<br />

been in the publishing business for 84 years.<br />

Other publications edited for specialized markets and distributed worldwide include:<br />

Forest Products Export Directory • <strong>Hardwood</strong> Purchasing Handbook • Dimension & Wood<br />

Components Buyer’s Guide • Import/Export Wood Purchasing News • Imported Wood<br />

Purchasing Guide • Green Book’s <strong>Hardwood</strong> Marketing Directory • Green Book’s Softwood<br />

Marketing Directory • The Softwood Forest Products Buyer<br />

Paul J. Miller, Jr.................................................................................................................President<br />

Central States Editor<br />

Terry Miller ...........................................................................................Vice President – Sales Mgr.<br />

Northeast Editor<br />

Wayne Miller..............................................................................................................Vice President<br />

Canada & West Coast Editor<br />

Gary Miller .................................................................................................................Vice President<br />

Southeast Editor<br />

Barbara King ...........................................................................................................Travel Manager<br />

Virginia Sorensen....................................................................................................Finance Officer<br />

Sue Putnam.............................................................................................................................Editor<br />

Michelle Keller .......................................................................................................Associate Editor<br />

John Gray, Jr .................................................................................................................Art Director<br />

Walter Lee .....................................................................................................Associate Art Director<br />

Tammy Daugherty...........................................................................................Production Manager<br />

Charlene Jumper.................................................................................Green Book …Market Sales<br />

Lisa Carpenter.................................................................................................Circulation Manager<br />

Lexi Hardin ..........................................................................................Subscription & List Services<br />

ADVERTISING OFFICES:<br />

1235 Sycamore View, Memphis, TN 38134<br />

901-372-8280 FAX 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

e-mail addresses: ADVERTISING: tammy@millerpublishing.com<br />

EDITORIAL: editor@millerpublishing.com<br />

SUBSCRIPTIONS: circ@millerpublishing.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published monthly, except for<br />

two issues in December, for $55.00 per year and $65.00 (U.S. dollars) per year for Canada<br />

by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc., 1235 Sycamore View, Memphis, TN 38134.<br />

Periodicals Postage paid at Memphis, TN, and at additional mailing offices. POSTMASTER:<br />

Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, P.O. Box 34908, Memphis, TN<br />

38184. Publications mail agreement No. 40739074. Return undeliverable Canadian<br />

addresses to: P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

Website: www.gfhardwoods.com<br />

LUMBER FOR<br />

SALE<br />

FROM<br />

HAROLD WHITE<br />

LUMBER, INC.<br />

Manufacturers of Quality Appalachian <strong>Hardwood</strong> Lumber<br />

Harold White Lumber, Inc. features:<br />

* Quality bandsawn lumber<br />

* Excellent color and texture<br />

* 500,000 bf of kiln capacity<br />

* Planing mill facility<br />

* Moulding facility specializing in paneling, flooring,<br />

casing, doors and fingerjoint<br />

* Individual package tally and<br />

on-site container loading<br />

PROMPT WORLDWIDE SHIPMENTS<br />

CONTACT MIKE WHITE<br />

For Moulding and Millwork requests<br />

CONTACT LEE WHITE<br />

Harold White Lumber, Inc.<br />

2920 Flemingsburg Road • Morehead, KY 40351<br />

Phone (606) 784-7573 • Fax (606) 784-2624<br />

Email: mwhite@haroldwhitelumber.com<br />

MARCH/<strong>2011</strong> 3

HARDWOOD CALENDAR<br />

MARCH<br />

Appalachian Lumbermen’s Club, Meeting,<br />

Grandover Resort, Greensboro, N.C.<br />

Contact: 828-397-7481. <strong>March</strong> 10.<br />

<strong>Hardwood</strong> Manufacturers Association, <strong>2011</strong><br />

<strong>National</strong> Conference and Expo, Charleston,<br />

S.C. Contact: 412-244-0440. Mar. 14-16.<br />

APRIL<br />

Penn-York Lumbermen’s Club, Monthly<br />

Meeting, Host: Penn-Sylvan International,<br />

Seven Springs, Pa. Contact: 814-694-2311.<br />

April 18.<br />

NWFA, Annual Convention and Wood<br />

Flooring Expo, San Diego, Calif. Contact:<br />

Convention@NWFA.org. April 26-29.<br />

MAY<br />

Woodworking Industry Conference,<br />

Marriott Marco Island Resort & Spa, Marco<br />

Island, Fla. Contact: 800-438-4373. May 3-<br />

6.<br />

WHAT ARE YOU UP TO NOW?<br />

Expanding your facilities, adding personnel or equipment, holding a meeting or convention?<br />

The <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> would like to know so that we can publish your announcement.<br />

Send news items to:<br />

editor@nationalhardwoodmag.com<br />

Appalachian Lumbermen’s Club, Meeting,<br />

Ocean Reef Resort, Myrtle Beach, S.C.<br />

Contact: 828-397-7481. May 12-15.<br />

Penn-York Lumbermen’s Club, Monthly<br />

Meeting, Host: Babcock Lumber, Seven<br />

Springs, Pa. Contact: 814-694-2311. May 16.<br />

•<br />

www.bingamanlumber.com<br />

12 Species<br />

Logs<br />

Lumber<br />

Strips<br />

Dimensions<br />

Ripping<br />

Surfacing<br />

More Than 10 Million<br />

Board Feet of Inventory<br />

More Than 1 Million<br />

Board Feet of Kiln Capacity<br />

Consistent Quality<br />

Decades of Experience<br />

Commitment to Service<br />

Bingaman & Son Lumber, Inc.<br />

P.O. Box 247 Kreamer, PA 17833 USA<br />

570.374.1108 Fax: 570.374.5342<br />

E-mail: info@bingamanlumber.com<br />

4 <strong>Hardwood</strong>s Have Versatility

YOUR OPERATION NEEDS TO BE MORE EFFICIENT THAN EVER.<br />

YOU NEED TO CUT COSTS AND INCREASE PRODUCTIVITY.<br />

AND THERE’S NO ROOM FOR ERROR.<br />

Today’s business climate demands you<br />

get more done with less resources. With<br />

an order this tall, you’ll need Hyster lift<br />

trucks to fi ll it. Tough, durable and reliable,<br />

they derive their power to perform from<br />

80 years of engineering excellence.<br />

This economy has extended a clear<br />

challenge. And our reply is, bring it.<br />

11HST3498<br />

#1 IN TOUGH APPS WORLD-CLASS SERVICE FULL PRODUCT LINE INDUSTRIAL GRADE PARTS<br />

PURPOSE-BUILT RETURN ON INVESTMENT PROVEN HERITAGE STRONG DEALER NETWORK<br />

hysteramericas.com<br />

© <strong>2011</strong> Copyright Hyster Company. Hyster and are registered trademarks of Hyster Company.

Supplier news about sales, labor, prices, trends, expansions and inventories.<br />

SOUTHEAST LAKE STATES WEST COAST<br />

<strong>Hardwood</strong> lumber suppliers<br />

throughout the southeast region<br />

account for spotty weather conditions,<br />

which make logging activity<br />

difficult. “Our winter has been<br />

challenging to say the least,” a<br />

source in Arkansas noted.<br />

“We’ve had heavy rain and snow<br />

with cold then warm weather following.”<br />

As a result the supplier said<br />

green lumber production for his<br />

particular operation has been limited.<br />

“There are other, larger<br />

mills that have adequate log<br />

decks right now. We’re a small<br />

mill and weather conditions tend<br />

to hit our operation in a big way.”<br />

He commented that he expects<br />

competition for green lumber<br />

orders to intensify as we move<br />

into warmer temperatures in the<br />

spring. “At the end of 2010 we<br />

had a decrease in sawmill production<br />

due to weak market conditions,”<br />

he explained. “That<br />

short decrease eased oversupply<br />

issues. I think that competition<br />

for green orders will be intense<br />

for the second quarter and prices<br />

will come up on many species,<br />

particularly in the Common<br />

grades.”<br />

<strong>Hardwood</strong> lumber suppliers in<br />

the Lake States region report<br />

mixed market conditions. An<br />

Indiana source described business<br />

as “terrible,” while a contact<br />

in Michigan said sales activity<br />

for his operation is on an upward<br />

pace.<br />

“Activity in Indiana is slow<br />

right now,” the supplier said. “We<br />

don’t have a lot of inventory<br />

because we don’t see any<br />

demand.”<br />

Marketing Red and White Oak,<br />

Walnut, Ash, Cherry and Hard<br />

and Soft Maple, she said Red and<br />

White Oak and Walnut is her best<br />

moving species and Cherry is the<br />

slowest. She mentioned she was<br />

thankful for their export markets.<br />

“If we didn’t have our exports, I<br />

don’t know where we would be<br />

right now. Our domestic markets<br />

are not good right now but our<br />

exports have been very good,”<br />

she explained.<br />

As for transportation issues she<br />

said her customers have been<br />

having a difficult time. “Our customers<br />

are responsible for their<br />

own trucking and several of them<br />

have mentioned they are having<br />

trouble finding trucks to pick it<br />

Please turn to page 42 Please turn to page 42<br />

<strong>Hardwood</strong> lumber market activity<br />

on the West Coast is spotty.<br />

Suppliers in California report no<br />

real change in sales movement<br />

while Oregon sources describe<br />

continued improvement in overall<br />

business conditions<br />

“We are seeing a lot of positive<br />

signs for an increase in business in<br />

the coming months,” a <strong>Hardwood</strong><br />

supplier in Oregon stated. “Many<br />

of us made decisions in the previous<br />

two years that are benefiting<br />

us right now. Some of us had to<br />

cut our labor cost along with<br />

inventories. Others had to stop<br />

producing for a while and some<br />

never came back. All those decisions<br />

put us in the position we are<br />

in today. It’s been a slow recovery,<br />

but it is a recovery.<br />

“The overall attitude in our<br />

industry has seen a vast improvement<br />

in the past six months.<br />

Nobody expects an overnight<br />

overhaul, but we look for some<br />

increases by the third quarter,” he<br />

continued.<br />

The source, who handles most<br />

domestic <strong>Hardwood</strong> species and a<br />

few exotics, also mentioned most<br />

of his furniture, flooring and cabinet<br />

manufacturer customers report<br />

Please turn to page 54<br />

NORTHEAST<br />

Contacts in the northeast region<br />

account for varied degrees of<br />

<strong>Hardwood</strong> lumber market activity.<br />

A Pennsylvania <strong>Hardwood</strong> supplier<br />

said his local markets are<br />

stable. “I think we hit the bottom<br />

several months ago on the<br />

demand side. On the price side<br />

we’re still seeing some price<br />

reductions on low-grade lumber.<br />

The prices on our No. 2 and 3<br />

Common Red and White Oak<br />

have firmed up recently along<br />

with log prices.”<br />

Expecting a seasonal pick-up in<br />

activity he said, “Hopefully as we<br />

move into the spring months into<br />

the second quarter I think we’ll<br />

see a pick-up. Exports are going<br />

really strong. Globally we’ve<br />

seen an uptick in business overall.<br />

Domestically we’re starting<br />

to see orders pick up as well. It’s<br />

nothing that’s going to cause us<br />

to increase our production hours<br />

here, but none the less, it’s a<br />

pleasant surprise to see the orders<br />

increase from the domestic side.”<br />

In Connecticut, a source commented,<br />

“It’s tough sledding right<br />

now with no profit margins.”<br />

When asked to what he attrib-<br />

Please turn to page 55<br />

6 <strong>Hardwood</strong>s...A Renewable Resource

QUEBEC<br />

As 2010 came to a close, several executives at lumber companies<br />

offered a glimmer of hope going into the new year. They said, however,<br />

not to expect a dramatic turnaround. Most sectors within the<br />

industry, they added, are looking at a continuing slow economic<br />

recovery. It should be seen as a gradual occurrence; taking several<br />

quarters, rather than several months.<br />

One of the lessons they learned as a result of the U.S. housing<br />

crash, is the importance of developing a more diverse customer<br />

base. Several companies expanded their customer base not only to<br />

other Canadian provinces but to overseas markets as well, such as<br />

China, India and Europe. Others have successfully diversified or<br />

completely changed their product offerings.<br />

Heads of companies also forecasted that mills will run for the year<br />

rather than just parts of it, with shifts getting back on track, and<br />

companies that had closed indefinitely possibly restarting.<br />

Most sawmills reported adequate log supplies for current market<br />

conditions, but expressed concerns about the future, stating that<br />

with current lumber prices they were unable to replace the standing<br />

timber they were logging, and their log inventory was dropping<br />

fast. Most mills were trying to push down log and timber prices, but<br />

some raised their buying prices slightly to help keep supplies flowing.<br />

Component manufacturers provided some activity for Ash suppliers,<br />

as they bought large quantities of the species while demand<br />

from other sectors was at slower pace. Sales of Basswood had<br />

increased according to manufacturing contacts. Yellow Birch sales<br />

were still difficult to come by, but things usually pick up for this<br />

species by spring.<br />

However, on the furniture manufacturing side and the residential<br />

interior fittings, things have slowed somewhat. Business for sports<br />

flooring has been holding up, which was of great surprise to many<br />

in the industry.<br />

News from suppliers about prices,<br />

trends, sales and inventories.<br />

ONTARIO<br />

Many sawmills and wood products manufacturers resumed operations<br />

in mid- to late January, while others remained closed following<br />

the Christmas break, and staying closed for another month or<br />

two due to poor market conditions. Many sawmills were trying to<br />

push log prices lower, and were uncertain if they would have<br />

enough supply to build log decks for the spring thaw period. It was<br />

also reported that exports to most European markets stayed slow<br />

over the past few months.<br />

One moulding manufacturer stated he was using more Basswood<br />

because customers were looking for something cheaper than<br />

Cherry, Red Oak or Soft Maple. Hard Maple was not one of the<br />

best sellers of 2010, with its recent activity being rated as very<br />

slow. And, recent sales of Hard Maple were hard to come by, but<br />

there was a noted general softening of most grades during the<br />

month, with sales dropping slightly.<br />

One source contacted commented that No. 1 Common Soft Maple<br />

was being used as a substitute for Cherry, reducing the premium<br />

manufacturers were willing to pay for Sap/Better stock.<br />

There has been increased consumer interest in Red Oak, albeit the<br />

shift has been minor. Red Oak sales had been slower towards the<br />

end of 2010. White Oak prices continued to mildly soften under<br />

pressure from slowing exports. Walnut demand has increased<br />

again, making a sufficient supply of this species difficult to find.<br />

The species was reported as a consistent seller in the U.S. border<br />

states.<br />

According to industry forecasts, business conditions will be quite<br />

challenging for <strong>Hardwood</strong> strip flooring manufacturers during the<br />

first six months of <strong>2011</strong>, and some even say most likely for the<br />

whole year. This is caused by the slow housing recovery in the<br />

U.S., the high Canadian dollar, the slower new home construction<br />

and existing home sales being down as well in certain parts of<br />

Canada. Several flooring manufacturers took extended downtime,<br />

Please turn to page 56 Please turn to page 57<br />

MARCH/<strong>2011</strong> 7

Eye On Technology<br />

HYSTER SHOWCASES H300HD LIFT TRUCK<br />

AND INTRODUCES E30-40XN SERIES<br />

Hyster Co., based in Danville, Ill., recently showcased its H190-<br />

360HD heavy-duty pneumatic lift truck series at a World of Concrete<br />

Show.<br />

The H190-360HD series, with lifting capacities of 19,000 to 36,000<br />

lbs., features a standard low-emission Cummins QSB 6.7 Tier 3<br />

industrial diesel engine with turbocharger and intercooler.<br />

Hyster also unveiled its next generation of electric lift trucks recently.<br />

The new Hyster E30-40XN series delivers lifting capacities of<br />

3,000 to 4,000 lbs. and offers significant performance and versatility<br />

for a wide variety of material handling applications.<br />

“The E30-40XN series is one of the most operator-friendly ACpowered<br />

lift trucks in the world,” said Brett Schemerhorn, vice president<br />

of dealer sales, Hyster Company. “It sets a new standard in electric<br />

lift trucks by lowering overall operating costs and energy consumption<br />

while maximizing productivity. You can count on this workhorse<br />

to get the job done.”<br />

Hyster H300HD Lift Truck and Hyster E30-40XN series<br />

“This is a tough, smart and purpose-built lift truck,” Schemerhorn<br />

said. “It’s what you expect from Hyster.”<br />

Hyster Company is an operating division of NACCO Materials<br />

Handling Group, Inc. (NMHG), which employs approximately 4,500<br />

people worldwide. NMHG is headquartered in Cleveland, Ohio, and is<br />

8 <strong>Hardwood</strong>s Have Workability

Installation, Products and Services<br />

a wholly owned subsidiary of NACCO Industries, Inc. (NYSE:NC).<br />

Hyster and are registered trademarks of Hyster Company in the<br />

U.S. and other countries.<br />

MCDONOUGH MANUFACTURING REPORTS RECENT ACTIVITY<br />

Pike Lumber Co.’s new mill in Milan, Ind., started up the 1 st week<br />

of January. The new mill includes a McDonough 6-foot headrig as<br />

well as McDonough’s 7 th edger system. This edger system features<br />

McDonough’s ValueMax system, which allows an operator assisted<br />

visual defect upgrade of the optimizer’s solution and is Pike Lumber’s<br />

2 nd edger system of this kind.<br />

Rex Lumber Co.’s new tandem arbor lineal edger, for their new<br />

facility in Brookhaven, Miss., was tested in the shop in early January<br />

and shipped to the customer. This innovative machine design features<br />

two skewing saw boxes in one machine center. Sold to perform up to<br />

50 pieces per minute, once operating this will be one of, if not the,<br />

fastest edger in the world. This will be McDonough’s 8 th edger product<br />

since they started making edger’s just three years ago.<br />

For more information on McDonough Manufacturing’s custom line<br />

of sawmill machinery call 715-834-7755.<br />

PIERCE CONSTRUCTION ANNOUNCES ADDITIONS<br />

Pierce Construction and Machine of Petal, Mississippi announces<br />

two major additions to its already comprehensive line of Forest<br />

Products Equipment. Seeing a need for a small yet sturdy band mill<br />

head rig, Pierce purchased a proven design from Filer and Stowell.<br />

According to a Pierce representative, the new PCM High Air Strain<br />

48” Band Mill offers extreme flexibility. The same basic design can<br />

be used as a head rig, vertical resaw, or horizontal resaw. The representative<br />

also said using 18 – 20 gauge saws and kerfs as low as .080”<br />

will provide a mill maximum recovery from their logs.<br />

Coupled with the new PCM band mill head rig is the PCM Carriage.<br />

After an exhaustive research project Pierce took a clean sheet of paper<br />

and incorporated the best features it had found in current carriages.<br />

The PCM Carriage is offered in a set shaft and linear positioner models<br />

with 36”– 48” openings and two to five knees as required by the<br />

customer.<br />

•<br />

Many <strong>Hardwood</strong> suppliers’ footprints<br />

have come and gone, but one has stood<br />

bold and distinct for four generations<br />

in the Walnut business...<br />

Missouri-Pacific<br />

Lumber Co., Inc.<br />

Quality <strong>Hardwood</strong>s Since 1935<br />

694 DD Highway • Fayette, Missouri 65248-9635<br />

Phone: 800-279-7997 • Fax 660-248-2508<br />

www.mopaclumber.com<br />

MARCH/<strong>2011</strong> 9

NHLA News<br />

NHLA Offers A Multitude Of Educational Programs In <strong>2011</strong><br />

As <strong>2011</strong> begins, NHLA is unveiling plans for an<br />

exciting year to come. One particular area of interest<br />

is in educational programming. NHLA plans to host<br />

a multitude of educational programs during <strong>2011</strong>;<br />

from lumber grading and kiln drying short courses to<br />

educational seminars at this year's NHLA Annual<br />

Convention in Nashville.<br />

The spring and summer lineup includes two of<br />

NHLA's most favorably reviewed programs:<br />

Leadership, Management and Development<br />

Program and <strong>Hardwood</strong>s 101.<br />

The NHLA Leadership, Management and<br />

Development Program is divided into two sessions.<br />

The first of which will be held April 3-7 at NHLA<br />

headquarters in Memphis, Tenn., directed by Dr.<br />

Vaughn Grisham, a renowned leadership instructor.<br />

Session two will take place May 9-12 in<br />

Washington, D.C. lead by Deb Hawkinson,<br />

Executive Director of the <strong>Hardwood</strong> Federation and<br />

Grace Terpstra of Terpstra and Associates. The<br />

NHLA Leadership Program is limited to only 15<br />

participants. Interested individuals should contact<br />

NHLA Director of Education Chris Churchill immediately<br />

to secure their spot.<br />

by CHRIS CHURCHILL<br />

Director of Education<br />

<strong>National</strong> <strong>Hardwood</strong> Lumber Assoc.<br />

Memphis, Tenn.<br />

<strong>Hardwood</strong>s 101, is a four-day forest<br />

to market course that is truly an<br />

essential building block for a strong<br />

foundation within the <strong>Hardwood</strong><br />

industry. The program is perfect for office personnel<br />

or sales professionals who need to know more<br />

about the inner-workings of the business. The<br />

course will be held June 12-16 and offers a great<br />

line-up of speakers and instructors.<br />

We at NHLA continue in our pursuit to meet the<br />

needs of the <strong>Hardwood</strong> lumber industry and look<br />

forward to seeing industry members participating in<br />

all that NHLA has to offer in <strong>2011</strong>. For a complete<br />

list of all NHLA educational opportunities including<br />

the NHLA Inspector Training School please visit<br />

www.nhla.com or contact Chris Churchill at 901-<br />

399-7555 or c.churchill@nhla.com.<br />

•<br />

10 <strong>Hardwood</strong>s Have Resiliency

HMA & Solid <strong>Hardwood</strong><br />

Promotion<br />

Is There A Big Picture For American <strong>Hardwood</strong>s?<br />

Are you familiar with IBM Cognos’ advertisement “Business<br />

Intelligence is not an oxymoron?” (No, I’m not endorsing software or<br />

computer-based data analysis techniques.) The ad’s word usage was<br />

an attention-getter and it got me thinking about the meaning of these<br />

powerful words.<br />

• Business – “a commercial or industrial enterprise and the people<br />

who constitute it; the units that perform most of the economic activity<br />

in our economy”<br />

• Intelligence – “the ability to comprehend; to understand and profit<br />

from experience; aptitude in grasping truths, relationships, facts,<br />

meanings, etc.”<br />

• Oxymoron – “two words that conflict with each; words that do not<br />

agree with each other”<br />

For my money, “Business Intelligence” is not a contradiction of<br />

terms. (I’m siding with IBM on this one.) The words “business intelligence”<br />

do belong together. They compliment each other, significantly.<br />

For those of you that attended HMA’s recent <strong>National</strong> Conference<br />

and Expo in Charleston, I hope you will agree that there were more<br />

than a few great minds in that meeting room. And were it possible to<br />

tally the years of business experience on hand in that room, it would<br />

be a phenomenal number. For me, that’s business intelligence.<br />

In terms of the American <strong>Hardwood</strong> industry, I’m inspired when I<br />

think of HMA member businesses and the countless other <strong>Hardwood</strong>related<br />

businesses that have successfully “made their way” through<br />

by LINDA JOVANOVICH<br />

Executive Vice President<br />

<strong>Hardwood</strong> Manufacturers Association<br />

Pittsburgh, Pa.<br />

these difficult times. They did it by working “smart.” For me, that’s<br />

business intelligence.<br />

As an industry then, how should we be “connecting the dots” for<br />

the Big picture?<br />

From where I’m sitting - aligning projects with objectives; combining<br />

efforts, rather than duplicating them; putting aside all else,<br />

resolved to work for the industry’s greater good - will indeed connect<br />

the dots. For me, that’s business intelligence.<br />

If it takes a village to raise a child, it will be the unified voice of the<br />

American <strong>Hardwood</strong> industry that will make a difference in the marketplace.<br />

So as an industry, we need to think big! As an industry, we<br />

need to be aggressive! As an industry, we need to collaborate in order<br />

to impact change. For me, that’s business intelligence!<br />

The <strong>Hardwood</strong> Manufacturers Association is the only national<br />

<strong>Hardwood</strong> trade association with membership limited to U.S. sawmill<br />

and concentration yards. For more information about the work that<br />

we do for our membership, visit our websites at<br />

www.<strong>Hardwood</strong>Info.com; www.<strong>Hardwood</strong>Council.com, and<br />

www.HMAmembers.org or call (412) 244-0440.<br />

•<br />

12 <strong>Hardwood</strong>s...The All-Purpose Material

SFI<br />

SHELTER FOREST<br />

INTERNATIONAL<br />

CLIENT PROFILE<br />

CHRISTENSEN SHIPYARDS, LTD.<br />

VANCOUVER, WA. USA<br />

Shelter Forest International is a proud supply partner to the<br />

craftsmen of Christensen Shipyards. These craftsmen use<br />

TigerLITE panels for the interior cabinetry of their latest<br />

line of super yachts. TigerLITE sets a new standard in<br />

performance, with its high strength to weight ratio.<br />

SFI has set up an efcient, vertically integrated supply chain<br />

to design, produce and deliver TigerPLY to the worlds most<br />

demanding craftsmen.<br />

Photos by Stephen Cridland<br />

TigerLITE Specs:<br />

Available in Thickness size of:<br />

12mm x 4’ x 8‘ ..............32 lbs<br />

15mm x 4’ x 8‘ ..............39 lbs<br />

18mm x 4’ x 8‘ ..............46 lbs<br />

Available Face Species:<br />

White Birch, Natural Birch, White Maple, Alder,<br />

Okume, and now in Bamboo.<br />

Performance Data:<br />

AVG. MOR(Strength) =<br />

MOE (Stiffness) =<br />

Screw Withdrawal<br />

Peak Load =<br />

CARB Phase 2 Certied.<br />

5099psi<br />

497,000psi<br />

266 lbs<br />

www.tigerply.com<br />

Shelter Forest International<br />

Portland, Oregon U.S.A.<br />

877-505-0900<br />

www.shelterforest.com<br />

MARCH/<strong>2011</strong> 13

AHEC Update<br />

Cautious Optimism In Europe, But Still A Ways To Go...<br />

As <strong>2011</strong> gets underway, European <strong>Hardwood</strong> traders and end-users<br />

are reporting a clear positive trend in most markets, but, activity is<br />

still well below pre-recession levels, and there is concern that the real<br />

impact of the economic crisis, in terms of job losses and spending<br />

cuts, is yet to be fully felt in many markets. There is much uncertainty<br />

about the prospects for the coming year. A brief look at four of the<br />

most important markets for U.S. <strong>Hardwood</strong>s highlights some of the<br />

positive and negative aspects of the current conditions and shows that<br />

not all markets are doing better:<br />

Germany<br />

According to the trade press the German market for wood is<br />

improving. It appears that 2010 has been a better year for timber sales<br />

than many traders and importers had predicted. However, trading<br />

conditions are still far from ideal, but the year has ended with the<br />

<strong>Hardwood</strong> sector in reasonably good mood. German manufacturers<br />

and traders have seen the benefit of an improving domestic market,<br />

as their economy is doing better than most others in Europe. This also<br />

means it is a key target for export industries from other EU markets.<br />

For example, Germany is the most important export market for many<br />

high-end Italian furniture and kitchen producers.<br />

Construction is picking up again after a very slow 2009, although<br />

demand for new builds remains low but there is much more refurbishment<br />

and renovation going on as a result of consumers switching<br />

investment away from stocks and shares and back into property. This<br />

increased activity is helping demand for a range of <strong>Hardwood</strong> industries,<br />

especially the flooring sector. In terms of <strong>Hardwood</strong> demand,<br />

Oak is still number one and remains fashionable in all sectors. Beech<br />

demand continues to be poor and the same can be said of Maple and<br />

Cherry. The good news for U.S. <strong>Hardwood</strong> exporters is that German<br />

importers are important suppliers of <strong>Hardwood</strong> to manufacturers in<br />

central and eastern Europe, which helps explain why U.S. <strong>Hardwood</strong><br />

exports to Germany have been increasing even during a time of recession.<br />

On another positive note there are reports of increasing demand<br />

for Tulipwood.<br />

UK<br />

According to an article in the UK trade magazine, TTJ “the<br />

<strong>Hardwood</strong> business is hardly going to finish the year with a bang, but<br />

it’s not going out with a whimper either.” The article goes on to comment<br />

on reports from <strong>Hardwood</strong> traders that suggest that 2010 has<br />

been a satisfactory year overall as there has definitely been an<br />

improvement in trade from 2009. But business remains tough with<br />

importers and manufacturers continuing to take the short-term<br />

approach of buying little and often and for immediate delivery. With<br />

so much uncertainty still out there no one wants to hold more stock<br />

than is absolutely necessary but on the other hand, no wood, no sale!<br />

The joinery sector, so important to UK <strong>Hardwood</strong> consumption, is<br />

reasonably busy mainly related to renovation of existing buildings,<br />

by MICHAEL SNOW<br />

Executive Director<br />

American <strong>Hardwood</strong> Export Council<br />

Reston, Va.<br />

although recent reports suggest there may be a<br />

slight pick up in new build projects. There is<br />

also a bit more activity in the shop-fitting sector.<br />

Then of course there is the Olympics, this<br />

will only be applicable to the approved suppliers<br />

but many projects are now reaching the stage where <strong>Hardwood</strong> is<br />

required for interior fit outs. According to the TTJ report, the “top<br />

performing temperate species in 2010 were American White and<br />

European Oak.” American Walnut demand has also been good and<br />

Tulipwood demand has been strong in the joinery sector. However<br />

trade in Maple and Cherry is way down on a few years ago and Red<br />

Oak is still failing to make much headway and improve its market<br />

share. One key topic of conversation in the UK trade is Ash and the<br />

Emerald Ash Borer (EAB). UK has always been a good market for<br />

American Ash and demand has picked up again in recent years. Quite<br />

a few importers are reporting healthy sales of Ash but are concerned<br />

about supplies from the USA and some have had containers sent back<br />

because of non-compliance with current UK phyto-sanitary requirements.<br />

There are also reports of increased European Ash offers from<br />

suppliers trying to cash in on concerns about EAB. However, feedback<br />

suggests that the market generally prefers American Ash as it<br />

has a more consistent color and grain.<br />

There is also much discussion about the new illegal timber law and<br />

the implications for <strong>Hardwood</strong> importers. There is concern that there<br />

will be increased demand for third party certification to ensure legality<br />

and that this might restrict EU access for U.S. <strong>Hardwood</strong>s. The<br />

TTJ report suggested this might not be the case and quoted one<br />

importer as saying, “U.S. timber is widely perceived as legal and sustainable<br />

so I don’t think the EU legislation will be a barrier.” In<br />

response to whether there would be a shift more to European<br />

<strong>Hardwood</strong>s he concluded, “the Americans have a breadth of specification<br />

and, in key species, notably Oak, price in their favor.”<br />

Italy<br />

After a poor year for <strong>Hardwood</strong> sales in 2009, at least by Italian<br />

standards, 2010 has proved a better year. Importers and manufacturers<br />

are buying again having previously run their stocks right down.<br />

Of course we have not returned to pre-recession activity but there is<br />

a bit more optimism about than there was at the beginning of the year.<br />

Italy is the most important European market for U.S. <strong>Hardwood</strong> lumber<br />

sales and exports have improved this year. The latest import figures<br />

also confirm this trend with Italian imports of American<br />

Please turn to page 41<br />

14 <strong>Hardwood</strong>s Have Versatility

Component Trends<br />

WCMA To Update Cost Accounting Manual<br />

Given the current economic conditions and pressures of global competition,<br />

the <strong>Hardwood</strong> component industry is facing serious challenges<br />

to remain a profitable manufacturing sector of our economy.<br />

Wood component production is of critical importance to the<br />

<strong>Hardwood</strong> value chain as it provides a market for the higher value<br />

and more profitable <strong>Hardwood</strong> products derived from our nation’s<br />

forests. To assure continued viability of the component industry,<br />

manufacturers need to improve their knowledge and use of product<br />

costing methodologies to facilitate better business decisions.<br />

To meet this need, the Wood Component Manufacturers Association<br />

(WCMA) is conducting a value-added <strong>Hardwood</strong> products costing<br />

project in cooperation with the Wood Education & Resource Center<br />

(WERC). A big part of this project will be to update the WCMA’s<br />

existing “Cost Accounting Manual.” The manual will be revised in<br />

close cooperation with WCMA member companies and be of major<br />

benefit to all <strong>Hardwood</strong> dimension and component producers.<br />

Primary researchers for the project are Urs Buehlmann with the<br />

Department of Wood Science & Forest Products at Virginia Tech and<br />

Jan Wiedenbeck with the Forestry Sciences Laboratory of the U.S.<br />

Forest Service. This project will investigate current product costing<br />

practices of <strong>Hardwood</strong> component producers, then update those practices<br />

using state-of-the-art knowledge, and disseminate this information<br />

to the industry.<br />

Accurate product costing, i.e. the accounting for all expenses<br />

incurred when designing, manufacturing, selling, and servicing a<br />

product, is very important to the success of any business. Yet, it is<br />

one of the most difficult and poorly executed activities in many businesses,<br />

including the <strong>Hardwood</strong> industry. Better cost information has<br />

been identified as one of the most critical needs for success for<br />

dimension and component manufacturers. This is because component<br />

producers respond to many sales inquiries on a regular basis and<br />

need to give potential buyers fast and accurate quotes. With today’s<br />

competitive pressures, these quotes need to be as accurate as possible<br />

in order to gain the business while still generating a profit.<br />

Cost information has four major purposes:<br />

• To determine the cost of producing products<br />

• To aid in pricing products<br />

• To aid in measuring performance<br />

• To aid in decisions on purchasing new machinery or equipment<br />

Product costing, an activity under the umbrella of cost accounting,<br />

is a critical tool for manufacturers to know, with a high-degree of<br />

by STEVE LAWSER, CAE<br />

Executive Director<br />

Wood Component<br />

Manufacturers Assoc.<br />

Marietta, Ga.<br />

accuracy, the full cost profile of all products<br />

being manufactured. Only by knowing accurate<br />

and true product costs can businesses make<br />

decisions and transactions based on reliable<br />

information, thus enabling the optimization of<br />

their business success. The costing process begins with the receipt of<br />

green lumber, through drying, rough mill, finish mill, and shipping.<br />

The updated cost accounting manual will include sections on<br />

• Cost accounting principles<br />

• Different types of cost accounting systems<br />

• Accounting for and controlling material costs<br />

• Accounting for and controlling labor costs<br />

• Accounting for and controlling overhead costs<br />

• Pricing techniques<br />

• Management reports<br />

• Implementation and use of costing systems<br />

The manual will also include a “cost of doing business” section to<br />

develop a basis for comparing financial information, similar to Dun<br />

& Bradstreet. The WCMA conducts a “cost of doing business” study<br />

of their members biennially. This survey reports on 25 key financial<br />

operating ratios in the critical areas of profitability, financial management,<br />

asset management, inventory management, investment management,<br />

cost management, and worker productivity. Participants<br />

are then able to compare their own company’s performance to the<br />

industry standards and norms, allowing them to target areas for<br />

improvement within their own operations.<br />

The WCMA represents 130 manufacturers of dimension and wood<br />

component products for the cabinet, furniture, moulding & millwork,<br />

flooring, building products, and related decorative wood products<br />

industries. Member companies are located throughout the United<br />

States and Canada.<br />

For more information, contact the WCMA office at Tel: (770) 565-<br />

6660. Email: wcma@woodcomponents.org. Or visit the WCMA’s<br />

website at www.woodcomponents.org.<br />

•<br />

16 <strong>Hardwood</strong>s...A Renewable Resource

•<br />

Web Site – www.fitzweller.com<br />

Sales – Dana Fitzpatrick, Greg Fitzpatrick, Joe Snyder,<br />

J.C. Fritz, Jeremy Stitt<br />

Products – Balusters, Bed Posts, Bench Tops,<br />

Bendings, Blanks, Blocks & Cleats,<br />

Boxes/Crates/Container Panels, Brush Blocks, Bun<br />

Feet, Cabinet Doors, Cabinet Parts/Accessories,<br />

Carvings, Case Good Parts, Chair Parts, Columns,<br />

Component Part, Crib Parts/Slats, Cue Blanks,<br />

Custom Shapes, Cut Stock, Cutting Boards,<br />

Dimension Parts/Components, Doors, Door Parts,<br />

Dowels/Dowel Parts, Drawers and/or Drawer Parts,<br />

Finger Joint & Finger Joint Edge-Glued Parts,<br />

Flooring, Frame Parts, Furniture Parts/Components,<br />

Handles, Handrails, Industrial/Display Components,<br />

Jambs, Joining Biscuits, Kiln/Stacking Sticks, Legs,<br />

Lumber, Machined & Semi-Machined Components,<br />

Millwork, Moudings-Crown, Custom, Dentil, Embossed,<br />

Moulded & Tenoned Parts, Moulder Blanks, Mouldings,<br />

Musical Instrument Parts, Newels/Newel Posts,<br />

Pallets-Heat Treated, Paneling, Panels, Pedestals,<br />

Posts, Profiles (Decorative Parts), Pulls, Shelving,<br />

Specialty Items, Squares, Stair Treads, Stairs/Stair<br />

Parts, Stiles and/or Rail Stock, Store Fixture, Parts,<br />

Strip, Surveyor Stakes, Table Tops/Parts, Toy Parts,<br />

Trim, Turnings, Window Parts<br />

Species – Hard & Soft Maple, Cherry, Red & White<br />

Oak, Ash, Poplar, Walnut, Mahogany<br />

Machining Capabilities – Boring, Sanding, Tenoning,<br />

Moulding, CNC Machine Center<br />

Dry Kiln Cap. – 400,000 BF<br />

Indiana Dimension, Inc. (Page 15)<br />

1621 W. Market St., P.O. Box 568, Logansport, IN 46947<br />

Tel: (888)875-4434 Fax: (574)739-2818<br />

Web Site: www.indianadimension.com<br />

Sales – Jeremy Rentschler, Roy Rentschler<br />

Marketing Areas – International, <strong>National</strong><br />

Products - Mouldings, Cabinet Doors, Edge Glued<br />

Panels, S4S Products, <strong>Hardwood</strong> Dimension, Ready-to-<br />

Assemble Component Parts, Blanks, Cabinet Parts, Cut<br />

Stock, Doors, Door Parts, Furniture Parts, Moulded<br />

Parts<br />

Species - Northern & Appalachian <strong>Hardwood</strong>s,Poplar,<br />

Red Oak, Ash, Hickory, Hard Maple, Cherry, Walnut,<br />

Alder, White Soft Maple, White Oak<br />

Machining Capabilities – Sanding, Shaping, Tenoning,<br />

Water Based Finishing Capabilities<br />

Inter-Continental <strong>Hardwood</strong>s, Inc.<br />

(Inside Front Cover)<br />

6841 Malpass Corner Road<br />

P.O. Drawer 119, Currie, NC 28435<br />

Tel: (910)283-9960<br />

Fax: (910)283-9964<br />

Web Site - www.ichardwoods.com<br />

E-Mail – info@ichardwoods.com<br />

Sales –Jim Mills, Lenny Shibley, Fred Coffrin<br />

Marketing Areas – <strong>National</strong>, International<br />

Products - Squares, Dimension, Flooring, Machined<br />

Products, Lumber<br />

Species - Bloodwood, Lacewood, Jatoba, Iroko, Ipe,<br />

Goncalo Alves, Spanish Cedar, Morado, European<br />

Beech, Bubinga, Aniegre, Cumaru, Afrormosia, Teak,<br />

Zebrawood, Genuine Mahogany, Sipo Utile, African<br />

Mahogany, Santos Mahogany, Purpleheart, Peruvian<br />

Walnut, Sapele, Padauk, Mansonia, Makore, Wenge<br />

Machining Capabilities - Distribution/Concentration<br />

Yard, 5 Dry Kilns, 3 Warehouses, Pre-Dryers,<br />

Green/Dry Chain, Sawmills in Gabon, Congo – Ghana,<br />

Offices in Africa, Asia, Europe, South America<br />

Jay-Gee Wood Products Co., Inc. (Page 5)<br />

28W206 Commercial Avenue, Barrington, IL 60010<br />

Tel: (847)381-7200<br />

Fax: (847)381-0078<br />

Web Site – www.jaygeewood.com<br />

E-Mail – pfreund@jaygeewood.com<br />

Sales – Peter C. Freund<br />

Marketing Areas – International, <strong>National</strong><br />

Products - Cutting Boards, Blanks, Edge-Glued Panels,<br />

RTA Furniture Parts, Mouldings, Kitchen Items, Desk<br />

Accessories, Flooring, Laminated Squares, Clocks,<br />

Plaques, Flat Panels, Picture Frames<br />

Species - Ash, Walnut, Hard Maple, Soft Maple, Red<br />

Oak, Poplar, Cherry, All North American <strong>Hardwood</strong>s,<br />

Machining Capabilities - Full Finish Capabilities, Boring,<br />

Routing, Sanding, Shaping, Finishing, Cut-to-Size,<br />

Color & Grain Matching, CNC Machining<br />

Appalachian Lumber Co., Inc. (Page 6)<br />

5879 W. US Hwy 421, Wilkesboro, NC 28697<br />

Tel: (336) 973-7205/ (800) 298-3202<br />

Fax: (336) 973-8356<br />

Web Site – www.appalachianlumber.net<br />

Email – plankfloors@wilkes.net<br />

Sales – William Church, William Parsons, Scotty Roten<br />

Marketing Areas – <strong>National</strong><br />

Products – Edge-glued Panels, Stair Treads, Stair<br />

Risers, Architectural Mouldings, Custom Mouldings,<br />

Plank Flooring, Paneling, Moulder Blanks<br />

Species – Red Oak, White Oak, Hard Maple, Soft<br />

Maple, Poplar, Walnut, Ash, Cherry, Hickory, Eastern<br />

White Pine, Eastern Yellow Pine<br />

Machine Capabilities – Moulding, Sanding, Tenoning,<br />

Edge Gluing<br />

Dry Storage Cap. – 500,000 BF<br />

Begley Lumber Company, Inc. (Binder & Page 32)<br />

P.O. Box 2800, London, KY 40743<br />

Tel: (606)877-1228<br />

Fax: (606)877-1230<br />

www.begleylumber.com<br />

Email – jpatterson@beglumber.com<br />

Sales – Matt Begley, John Patterson<br />

Products - Mining, Flooring, Pallet Lumber, <strong>Hardwood</strong><br />

Mulch, High Grade Appalachian <strong>Hardwood</strong>s<br />

Species - Walnut, Red Oak, White Oak, Chestnut Oak,<br />

Hickory, Poplar, Beech, Soft Maple, Ash, Hard Maple<br />

Machining Capabilities - Hyden, KY - Bandmill,<br />

Automatic Band Mill, Bull-Edger, Trimmer, Debarker,<br />

Chipper, Anti-Stain and Bug Dip, Mulch Processing<br />

Dry Kiln Cap. – 740,000 BF<br />

Dry Storage Cap. – 3,000,000’<br />

Churchtown Woodcraft (Inside Back Cover)<br />

2095 Main St., Churchtown, PA 17555<br />

Tel: (717)445-7988<br />

Fax: (717)445-4872<br />

E-mail – churchtownwoodcraft@frontiernet.net<br />

Sales – Carl E. Zimmerman<br />

Marketing Areas – Regional<br />

Products - Jambs, Bench Tops, Drapery Rods,<br />

Drawers, Frame Parts, Furniture Parts/Components,<br />

Dimension Parts/Components, Industrail Components,<br />

Decking, Legs, Machined Components, Millwork,<br />

Moldings (Custom), Moulded Parts, Moulder Blanks,<br />

Handles, Chair Parts, Blanks, Blocks, Brush Blocks,<br />

Cabinet Doors, Cabinet Parts/Accessories, Doors,<br />

Case Good Parts, Profiles (Decorative Parts), Columns,<br />

Component Parts, Crib Parts/Slats, Custom Shapes,<br />

Cut Stock, Cutting Boards, Carvings, Toy Parts, Semi-<br />

Machined Components, Display Components, Musical<br />

Instrument Parts, Tenoned Parts, Posts, Rail Stock,<br />

Door Parts, Drawer Parts, Cleats, Trim, Window Parts,<br />

Table Tops/Parts, Store Fixture Parts, Stiles, Stairs,<br />

Stair Treads, Specialty Items, Shelving, Stair Parts,<br />

Brackets<br />

Species – All types of Wood – Domestic, Imports &<br />

Exports<br />

Machining Capabilities – CNC Routing Machine, Chop<br />

Saws, Wide Belt Sanders, Table Saw, Jointer, CNC<br />

Tenoner Machine, CNC Laser Engraver, Sign Carving,<br />

5,000 SF Plant.<br />

Custom Molding (Page 19)<br />

9061 E. 875 N., Odon, IN 47562<br />

Tel: (812)636-7110<br />

Fax: (812)636-0044<br />

Sales – John Graber<br />

Marketing Areas – Regional<br />

Products - Exterior Doors, Rope Moldings, Legs,<br />

Jambs, Handrails, Flooring, Components, Dimension<br />

Parts, Cut Stock, Bunfeet, Molder Blanks, Stairway<br />

Parts, Shelving, Interior Doors, Handles, Vinyl<br />

Windows, Turnings, Cabinet Parts, Furniture Parts,<br />

Blanks, Embossed <strong>Hardwood</strong> Moldings, <strong>Hardwood</strong><br />

Moldings, Dentil Moldings, Lumber, Stiles, Rail Stock,<br />

Strips, Surveyor Stakes, Millwork<br />

Species - White Oak, Poplar, Red Oak, Soft Maple,<br />

Hard Maple, Hickory, Cherry, Ash, Walnut<br />

Machining Capabilites - Molder, Embossing Machine,<br />

Rope Molder, Straight Line Ripsaw, Sanding, Shapers,<br />

Planers, Bandsaw, Resaw<br />

Dry Storage Cap. – 50,000 SF<br />

Fitzpatrick & Weller, Inc. (Page 9)<br />

12 Mill St., P. O. Box 490, Ellicottville, NY 14731<br />

Tel: (716)699-2393 Fax: (716)699-2893<br />

E-Mail – sales@fitzweller.com<br />

BUYERS!<br />

• •<br />

Lebanon Oak Flooring Co. LLC (Page 1)<br />

215 Taylor Ave., P.O. Box 669, Lebanon, KY 40033-0669<br />

Tel: (270)692-2128<br />

Fax: (270)692-2128<br />

Web Site – www.lebanonoak.com<br />

E-mail – lebanonoakflooring@windstream.net<br />

Sales – Robert L. Goodin, Richard T. Goodin<br />

Lumber Sales – Richard T. Goodin, Charles R. Goodin<br />

Marketing Areas – <strong>National</strong><br />

Products - Mouldings, Furniture, Kitchen Dimension<br />

Parts, Panels, Panels Edge- Glued, Stair Treads,<br />

Risers, Railing, Blanks, 5/16 sq. Edged Flooring, Strips<br />

& Plank, 3/8 x 1 1/2, 2”, 1/2 x 1 1/2, 2 1/4, 3/4 x 2 1/4,<br />

3 1/4, Drawer Sides, Tongue & Groove Flooring<br />

Species - Walnut, Red Oak, White Oak, Maple, Hickory,<br />

Cherry, Ash<br />

Machining Capabilities – Finger Jointing, Sanding<br />

Dry Kiln Cap. – 270,000’ (4 Kilns) per week<br />

Dry Storage Cap. – 5-600,000’<br />

MJB Wood Group, Inc. (Page 17)<br />

14780 SW Osprey Dr. #325, Beaverton, OR 97007<br />

Tel: (503)521-9663<br />

Fax: (503)521-9664<br />

Web Site – www.mjbwood.com<br />

E-Mail – bmonroe@mjbwood.com<br />

Sales – Brent Monroe<br />

Marketing Areas – <strong>National</strong>, International<br />

Products – Dimension, Plywood, MDF, Particleboard,<br />

Lumber/LVL, Panel Products, Mouldings & Millwork,<br />

Component Parts, Specialty Products<br />

Species – Domestic, Imports, Red Alder, PC Poplar<br />

Sitco Lumber Company (Page 23 & Back Cover)<br />

2050 Kestrel Avenue, DeSoto, TX 75115<br />

Tel: (972) 225-4283<br />

(800) 627-4826<br />

Fax: (972) 228-5987<br />

Web Site – www.sitco.com<br />

E-Mail- info@sitco.com sales@sitco.com<br />

Sales – Jess Fulcher – j.fulcher@sitco.com<br />

Steve McKeever – s.mckeever@sitco.com<br />

Pudge Shatzer – p.shatzer@sitco.com<br />

Bob Williams – b.williams@sitco.com<br />

Marc Barany – m.barany@sitcosa.com<br />

Jon Pappas – j.pappas@sitco.com<br />

Tony Jackson – t.jackson@sitco.com<br />

Kathy Mota – k.mota@sitco.com<br />

Marketing Areas – <strong>National</strong>, International<br />

Products – Lumber, Plywood, S2S, <strong>Hardwood</strong>s &<br />

Exotics<br />

Species – Domestic, Exotic & Imported <strong>Hardwood</strong>s<br />

Southland Wood Products, Inc. (Page 13)<br />

270 Newsome Rd., Wilsonville, AL 35186<br />

Tel: (205)669-1959<br />

Fax: (205)669-1959<br />

E-Mail – southlandwoodproducts@yahoo.com<br />

Sales – Tad Lidikay<br />

Marketing Areas – <strong>National</strong>, Regional<br />

Products - Cabinet Parts, Furniture, Rails, Dimension,<br />

Cut Stock, Blanks, Mouldings<br />

Species – Softwoods & <strong>Hardwood</strong>s<br />

Machining Capabilities - Profile Grinding Machine, 6-<br />

Head Wadkin Moulder, Straight Line Ripping, Gang<br />

Ripping, Moulding<br />

Dry Storage Cap. – 100,000 BF<br />

Stanley Woodworking, Inc. (Page 155)<br />

4113 White Top Rd., Middleburg, PA 17842<br />

Tel: (570)837-6434<br />

Fax: (570)837-1637<br />

Web Site – www.hardwoodparts.com<br />

E-Mail – contact.us@hardwoodparts.com<br />

Sales – Tom Fitzgerald<br />

Marketing Areas – <strong>National</strong><br />

Products – S4S Stock, Laminated Parts, Billiard & Pool<br />

Table Parts, Edge-glued Panels, Mouldings, Dimension,<br />

Squares, Stair Parts, Furniture Parts<br />

Species - Mahogany, Red Oak, White Oak, Cherry,<br />

Maples, Ash, Hickory, Walnut, Basswood, Poplar<br />

Machining Capabilities - Ripping, Chopsaws, Gluing,<br />

Moulding, Tenoning, Sanding, Finger Joint<br />

Dry Storage Cap. -1,000,000’<br />

Thompson Forest Products Intʼl (Page 2)<br />

24-B Battleground Court (27408)<br />

P. O. Box 9206, Greensboro, NC 27429<br />

Tel: (336)373-1117 Fax: (336)373-1119<br />

Web Site – www.thompsonforestproducts.com<br />

FOR MORE DETAILED SUPPLIER INFORMATION CHECK YOUR<br />

COPY OF THE DIMENSION & WOOD COMPONENTS BUYERʼS<br />

GUIDE. EACH FIRMʼS AD APPEARS ON THE PAGE NUMBER<br />

INDICATED IN “THE DIMENSION BOOK” ITSELF!<br />

TO LEARN MORE ABOUT OUR ANNUAL WOOD COMPONENT DIRECTORY, CONTACT US AT<br />

(901) 372-8280<br />

ITʼS THE ONLY WOOD TRADE PUBLICATION IN EXISTENCE THAT SOLELY PROMOTES THE DIMENSION AND WOOD COMPONENT INDUSTRY.<br />

E-Mail – billy@thompsonforestproducts.com<br />

bob@thompsonforestproducts.com<br />

Sales – Billy Thompson, Bob Thompson<br />

Marketing Areas – <strong>National</strong>, International<br />

Products - Dimension, Table Legs, Dowels, Bed Posts,<br />

CNC Shaped Parts, Components, Chair Assemblies,<br />

Mouldings, Edge Glued Panels, Turnings, Squares,<br />

Panels<br />

Species - Hickory, Ash, Maple, Beech, Gum, Pine, Oak,<br />

Poplar, Birch<br />

Machining Capabilites - Sanding, Tenoning, Moulding,<br />

Shaping, Routing, Boring<br />

Valley Line Wood Products (Page 21)<br />

2935 N. 500 W., Shipshewana, IN 46565<br />

Tel: (260)768-7807 Cell: (574)202-5614<br />

Fax: (260)768-3103<br />

E-Mail – valleyline@pcfreemail.com<br />

Sales – Danny Miller – danny.valleyline@gmail.com<br />

Marketing Areas – <strong>National</strong><br />

Products - Squares, Cabinet Parts, S4S <strong>Hardwood</strong><br />

Lumber, Trim, Edge Glued Panels, Strips, Drawers,<br />

Door Parts, Furniture, Blanks, Mouldings, Face Glued<br />

Panels, Drawer Parts, Stair Parts<br />

Species - Alder, Red Oak, White Oak, Hard Maple,<br />

Cherry, Elm, Ash, Poplar, Walnut, Others, Soft Maple<br />

Machining Capabilities - Sanding, Moulders, Edge<br />

Gluing Equipment, Chop Saws, Planer, Rip Saw,<br />

Optimizing Chop Saw, Shaping<br />

Wood Specialties de Mexico (Page 5)<br />

(Subsidiary of Jay-Gee Wood Products Company, Inc.)<br />

5811 East Dr. Ste. C, Laredo, TX 78041<br />

Tel: (847)381-7200<br />

Fax: (847)381-0078<br />

Web Site – www.jaygeewood.com<br />

E-Mail – pfreund@jaygeewood.com<br />

Sales – Peter C. Freund<br />

Marketing Areas – International, <strong>National</strong><br />

Products - Blanks, Flat Panels, Plaques, Clocks, Desk<br />

Accessories, Cutting Boards, Kitchen Items, Picture<br />

Frames, RTA Furniture, Edge Glued Panels<br />

Species - Hard Maple, Soft Maple, Red Oak, Ash,<br />

Poplar, Pine, Cherry, Walnut<br />

Machining Capabilities - Finishing, Boring, Routing,<br />

Sanding, Shaping<br />

Walnut Creek Planing Ltd. (Page 33)<br />

5778 State Route 515, Millersburg, OH 44654<br />

Tel: (330)893-3244<br />

(800)488-3244<br />

Fax: (330)893-2468<br />

E-Mail – sales@wcplaning.com<br />

Sales – Dwight C. Kratzer, Charles Kratzer<br />

Marketing Areas – International, <strong>National</strong><br />

Products - Balusters, S2S, Component Parts, Squares,<br />

Blanks, Component Parts, Surveyor Stakes, S4S, Door<br />

Stiles, Panels, Stair Treads, Custom Orders Welcome,<br />

Dowels, Chair Parts<br />

Species - Cherry, Maple, Beech, Soft Maple, Red Oak,<br />

Poplar<br />

Machining Capabilities – Sanding, Tenoning, Finger<br />

Jointing, Moulding, Ripping<br />

Yoder Lumber Company, Inc. (Page 210)<br />

4515 Berlin Twp. Rd. 367, Millersburg, OH 44654<br />

Tel: (330)893-3121<br />

Fax: (330)893-3031<br />

Web Site – www.yoderlumber.com<br />

E-Mail – sales@yoderlumber.com<br />

Sales – Paul Dow<br />

Marketing Areas – <strong>National</strong>, International<br />

Products – Moulded Parts, Semi-machined<br />

Components, Moulder Blanks, Machined Components,<br />

Panels, Laminated Squares, Squares, Balusters<br />

Species - Hard Maple, Cherry, Walnut, Soft Maple,<br />

White Oak, Beech, Poplar, Red Oak<br />

Machining Capabilities - PET, Sanding, Gluing, Ripping,<br />

S2S, Moulding<br />

Dry Kiln Cap. – 500,000 BF<br />

Dry Storage Cap. – 2,500,000 BF<br />

MARCH/<strong>2011</strong> 17

LEBANON OA<br />

OVER A CENTU<br />

1<br />

Lebanon, Ky.– It takes a lot to rattle the folks at Lebanon Oak<br />

Flooring Co., LLC. Even the current recession hasn’t been able to keep down<br />

a company that’s seen more than its fair share of economic ups and downs<br />

since being founded in the late-1800s.<br />

Where many firms across multiple industries have opted to stick their heads<br />

in the sand and wait out the downturn, Lebanon Oak Flooring is standing tall,<br />

finding new customers and exploring new product and service opportunities.<br />

18 <strong>Hardwood</strong>s Have Workability

K FLOORING<br />

RY OF SUCCESS, AND<br />

STILL GOING STRONG<br />

BY BRIDGET MCCREA<br />

2<br />

3<br />

4<br />

Credit the firm’s long history of success<br />

with insulating it from the negative economic<br />

conditions. A manufacturer of multiple<br />

wood products, including <strong>Hardwood</strong><br />

flooring (which makes up about half of<br />

the firm’s business), stair treads, risers,<br />

handrails, mouldings and edged glued<br />

panels, Lebanon Oak Flooring boasts a<br />

diversified product mix. The 60-employee<br />

company operates from 26 acres of land<br />

and 150,000 square feet of covered space<br />

here.<br />

Lebanon Oak Flooring uses about<br />

300,000 board feet of lumber every<br />

month, primarily 4/4 and 5/4 Red and<br />

White Oak, Maple, Hickory, Cherry,<br />

Ash and Walnut. Rick Goodin, plant<br />

manager, said the firm prefers<br />

Appalachian Oak, which it buys from<br />

sawmills and brokers in Kentucky,<br />

Southern Indiana, Southern Ohio,<br />

Tennessee, West Virginia and North<br />

Carolina. A sales team based in Lebanon<br />

and California sells to customers throughout<br />

North America.<br />

Rewind back to the late-1800s and<br />

Lebanon Oak Flooring got its start as a<br />

sawmill. In the early-1900s, it began man-<br />

Please turn to page 34<br />

1. Sixty employees manufacture Lebanon<br />

Oak’s products from a facility constructed on<br />

26 acres of land.<br />

2. Today, Lebanon Oak Flooring produces<br />

flooring in various thicknesses, including<br />

5/16-inch “top nail flooring,” which is<br />

becoming rare in the U.S.<br />

3. Lebanon Oak’s plant covers 150,000<br />

square feet of space.<br />

4. Other popular flooring sizes produced by<br />

Lebanon Oak Flooring include 3/4, 3/8, and<br />

1/2-inch tongue and groove.<br />

MARCH/<strong>2011</strong> 19

Neff Lumber<br />

Manufacturing Quality Appalachian <strong>Hardwood</strong>s<br />

BY GARY MILLER<br />

Broadway, Va.— From their six-foot band mill operation Neff Lumber Mills<br />

Inc., based here, manufactures green and kiln-dried Appalachian <strong>Hardwood</strong> lumber, heat<br />

treated pallets, skids, survey stakes, fenceboards, chips, mulch, sawdust and strips.<br />

Founded in 1928 by Newton A. Neff and Blair A. Neff, the company<br />

is family-owned and operated and produces approximately 5<br />

million board feet of Appalachian <strong>Hardwood</strong> lumber per year.<br />

Species offered by Neff Lumber include: Red and White Oak,<br />

Ash, Poplar, Cherry and steamed Black Walnut.<br />

In order to satisfy its broad customer base, Neff Lumber uses<br />

state-of-the-art sawmill equipment. Located in the Shenandoah<br />

Valley of Virginia, the 20-acre mill site includes SII dehumidification<br />

dry kilns; a computer operated linear positioner Corley carriage;<br />

a Fulghum debarker; a McDonough band saw; and a six-foot<br />

stacker. Rolling equipment includes Caterpillar forklifts.<br />

The company’s Appalachian <strong>Hardwood</strong> lumber is manufactured<br />

in thicknesses of 4/4 through 16/4. Neff mostly produces high<br />

grade <strong>Hardwood</strong>s and separates production according to customers’<br />

specifications for width and length.<br />

All of Neff’s lumber products are graded to <strong>National</strong> <strong>Hardwood</strong><br />

Lumber Association (NHLA) standards. Log Procurement<br />

Manager Mike Hoover said, “All of our kiln-dried lumber products<br />

are graded twice before they are prepared for shipment, once at the<br />

mill and again after kiln drying.” The firm’s dry kiln capacity is<br />

180,000 board foot per charge utilizing three dry kilns.<br />

Hoover continued, “Our Pendu gang saw has multiple uses. The<br />

industrial grade lumber goes into our Pendu system, which is used<br />

to cut up the lumber for pallets and stakes. The Pendu system is also<br />

used for ripping the lumber into strips in four through eight inch<br />

widths, which are made in six to 12 foot lengths.”<br />

Neff Lumber markets to a multitude of customers including different<br />

types of woodworking plants, <strong>Hardwood</strong> distribution/concentration<br />

lumberyards and exporters. Marijo Wood, sales manager for<br />

Neff Lumber Inc. said, “Our firm exports our lumber products to<br />

countries such as Denmark, Germany, England and China where it’s<br />

used for making <strong>Hardwood</strong> flooring, cabinets, window trim, and<br />

door frames.<br />

Our wood pallets are heat treated for export at 133 degrees,” Wood<br />

explained. “A hole is drilled in a piece of the material and we put a<br />

probe in to measure the temperature. When the temperature in our<br />

pallets reaches 133 degrees and stays at that temperature for about<br />

an hour, our pallets are ready for shipping to our various customers.”<br />

Please turn to page 40<br />

20 <strong>Hardwood</strong>s Have Resiliency

Several family members work at Neff Lumber Mills, Inc., including: Eric Hoover; Katie Hoover; Mike Hoover; Marijo Wood; Chris Hoover; and Matt Hoover.<br />

This is a view of Neff’s computer operated linear positioner Corley carriage and McDonough six-foot<br />

band saw.<br />

Danny Sherman grading the kiln dried lumber.<br />

The Caterpillar forklift operator is pushing the bundles of lumber into a container that will be shipped to one<br />

of Neff Lumber Mills, Inc.’s overseas customers.<br />

Neff Lumber Mills, Inc.’s large log yard has these main species<br />

of logs in inventory: Red and White Oak; Ash; Poplar,<br />

Cherry; and Walnut.<br />

MARCH/<strong>2011</strong> 21

Winter Wisconsin Meeting<br />

Enjoyed By LSLA Attendees<br />

BY WAYNE MILLER<br />

Green Bay, Wis.–<br />

Approximately 140 members and<br />

guests recently attended the <strong>2011</strong> winter<br />

meeting of the Lake States Lumber<br />

Association at the Radisson Hotel &<br />

Conference Center.<br />

Guest speakers for the meeting included<br />

Ross Bernstein, best-selling author of<br />

nearly 50 sports books, and Deb<br />

Hawkinson, executive director of the<br />

<strong>Hardwood</strong> Federation.<br />

Additionally, Travis Allen of the Wood<br />

Technology Center, based in Antigo,<br />

Wis., spoke of new technology in the<br />

wood industry and of the new 28,000<br />

square foot facility from which the center<br />

operates.<br />

Attendees also heard reports about the<br />

overall industry. Sources predicted that in<br />

Please turn to page 40<br />

LSLA Board of Directors are: (front row, from left) Gary Halpin, Riverside Sawmill, Muscoda, Wis.; Liz Russell,<br />

vice president, Stella-Jones Corp., Bangor, Wis.; Dave Sebastian, president, Big River Lumber Corp.,<br />

Trempealeau, Wis.; Scott Sawle, Rockbridge Sawmill Inc., Richland Center, Wis.; Will Borden, Quality<br />

<strong>Hardwood</strong>s Inc., Sunfield, Mich.; Mike Peterson, treasurer, Kretz Lumber Co. Inc., Antigo, Wis.; (back row,<br />