National Hardwood Magazine - March 2011

Check out the National Hardwood Magazine's latest issue and stay up-to-date on all the trends, news, and industry info you need.

Check out the National Hardwood Magazine's latest issue and stay up-to-date on all the trends, news, and industry info you need.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>March</strong> <strong>2011</strong><br />

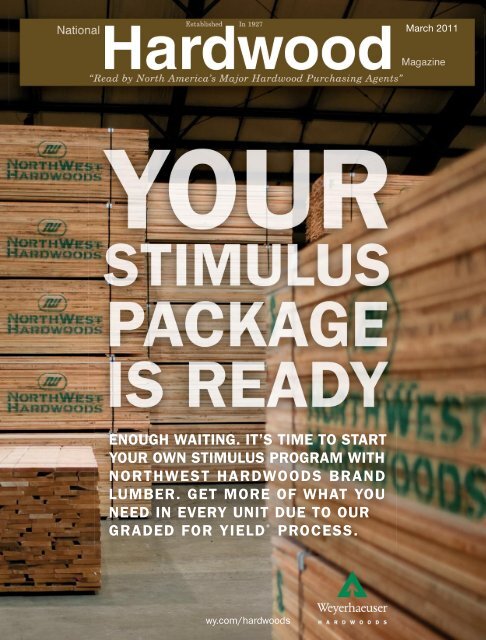

ENOUGH WAITING. IT’S TIME TO START<br />

YOUR OWN STIMULUS PROGRAM WITH<br />

NORTHWEST HARDWOODS BRAND<br />

LUMBER. GET MORE OF WHAT YOU<br />

NEED IN EVERY UNIT DUE TO OUR<br />

GRADED FOR YIELD ®<br />

PROCESS.<br />

wy.com/hardwoods

And We Think The World Of You Too!<br />

For more than 40 years, the<br />

Walter M. Fields Lumber Company<br />

has built a reputation for producing<br />

only the finest textured White Ash<br />

for users worldwide. We have more<br />

than 300,000 board feet of dry kilns,<br />

200,000 board feet of air drying buildings,<br />

and a 2 million board foot dry<br />

storage building. As well as on-site<br />

rail, truck and container shipping.<br />

And we’re located in Memphis,<br />

Tennessee, the hardwood capital of<br />

the world. A lot of wood. A lot of<br />

history. A dedication to meeting your<br />

most exacting standards. When it<br />

comes to ash, the world comes to<br />

Fields Lumber. Call us at 901/948-7751<br />

or visit www.fieldslumber.com<br />

Walter M. Fields Lumber Company<br />

Southern & Appalachian <strong>Hardwood</strong>s<br />

Quality • Service • Dependability<br />

P .O. Box 13231 • 2401 Harbor Avenue • Presidents Island • Memphis, TN 38113<br />

Phone: 901/948-7751 • Fax: 901/948-7752 • Website: www.fieldslumber.com

In today’s complex world<br />

at least one thing is plain and simple.<br />

At Cersosimo we provide you with the<br />

largest and most consistent supply of<br />

quality hardwood—from the heart of<br />

New England forests. And we’ve been<br />

doing it for over 55 years. You’ve come<br />

to count on us to be there and deliver<br />

the best—and do it consistently.<br />

It’s straight talk from folks who are<br />

easy to talk to, who know the business<br />

inside and out—and whose integrity<br />

is as solid as the lumber we provide.<br />

www.cersosimolumber.com

PUT SOME<br />

WIND<br />

BEHIND YOUR<br />

RECOVERY<br />

Dry kiln owners worldwide are<br />

stimulating their profits with<br />

Smithco propellers. Smithco's<br />

4, 6, 8 and 12 bladed propellers,<br />

ranging in size from 30" to 84,"<br />

can be configured for maximum<br />

air flow with lowest power<br />

consumption. Our reversible,<br />

adjustable blade propellers allow<br />

you to optimize the cost/benefit<br />

ratio for your kiln application.<br />

100% reversibility for uniform drying<br />

cycles and maximum through-put<br />

Permanent mold S-profile aluminum<br />

blades and hubs, heat-treated for<br />

longest life in kiln environment<br />

Precision hubs with stainless steel<br />

hardware, balanced for low-noise,<br />

vibration-free operation<br />

Fast, accurate blade pitch angle<br />

setting with Smithco’s exclusive<br />

Degree Gauge<br />

So choose the propeller with<br />

a proven return — Smithco!<br />

SMITHCO<br />

MANUFACTURING, INC.<br />

7911 N.E. 33rd Dr. Portland, OR 97211<br />

503-295-6590 Fax 503-295-6822<br />

800-764-8456 U.S.<br />

e-mail: sales@smithcomfg.com<br />

www.smithcomfg.com<br />

Contents:<br />

Features:<br />

Lebanon Oak Flooring: Over A Century Of Success, And Still Going Strong ...18<br />

Neff Lumber – Manufacturing Quality Appalachian <strong>Hardwood</strong>s .........................20<br />

Winter Wisconsin Meeting Enjoyed By LSLA Attendees......................................22<br />

NASCAR Spotter Offers Report To Appalachian Group .......................................24<br />

Dwight Lewis/Lewis Lumber Co-Host First Penn-York Meeting For <strong>2011</strong> ..........26<br />

International Builders Show Convenes In Orlando...............................................28<br />

SURFACESʼ Attendees Gain Guidance On Meeting Goals...................................32<br />

Departments:<br />

<strong>Hardwood</strong> Calendar.......................................................................................................4<br />

U.S.A. Trends .................................................................................................................6<br />

Canadian Trends............................................................................................................7<br />

Eye On Technology .......................................................................................................8<br />

NHLA News................................................................................................................10<br />

HMA & Solid <strong>Hardwood</strong> Promotion.........................................................................12<br />

AHEC Update ............................................................................................................14<br />

WCMA Component Trends.......................................................................................16<br />

Whoʼs Who ................................................................................................................44<br />

Trade Talk ..................................................................................................................48<br />

Classified Opportunities ..........................................................................................58<br />

Advertisers Index......................................................................................................60<br />

The publisher reserves the right to accept or reject<br />

editorial content and Ads at the staff’s discretion.<br />

2 <strong>Hardwood</strong>s...The All-Purpose Material

<strong>March</strong>, <strong>2011</strong> Vol. 85, No. 2<br />

The Cover<br />

Weyerhaeuser <strong>Hardwood</strong>s provides<br />

the furniture, cabinet and millwork<br />

industries with a single source for a<br />

broad range of products. The company<br />

is a manufacturer and global supplier<br />

of a wide range of hardwood lumber<br />

including: alder, hard and soft maple,<br />

cherry, red and white oak, hickory,<br />

walnut, yellow poplar and European<br />

beech.<br />

Also available are hardwood and<br />

softwood plywood and wood components.<br />

For more information call 866-870-3040, email – hardwoods@weyerhaeuser.com<br />

or visit the company website:<br />

www.wy.com/hardwoods.<br />

G.F. <strong>Hardwood</strong>s, Inc.<br />

“A Company You Can Depend On”<br />

Species<br />

9880 Clay County Hwy.<br />

Moss, TN 38575-6332<br />

Phone: 1-800-844-3944<br />

Fax 1-931-258-3517<br />

Kevin Sweezy<br />

kevin@gfhardwoods.com<br />

Quality Appalachian<br />

<strong>Hardwood</strong> Lumber<br />

Services<br />

Facilities<br />

• Red Oak<br />

• Poplar<br />

• Hard Maple<br />

• White Oak<br />

• Ash<br />

• Cherry<br />

• Own Trucks<br />

• Cut 4/4<br />

through 8/4<br />

• Grade After Kiln<br />

Drying<br />

• Computer Tally<br />

• 5 Length<br />

Separations<br />

• 800,000 B.F.<br />

Kiln Capacity<br />

• 500,000 B.F.<br />

Predryer<br />

Capacity<br />

• Yates American<br />

Planer<br />

Founded in 1927 by:<br />

O.L. MILLER - 1894 - 1963<br />

Publisher: PAUL J. MILLER - 1963 - 2010<br />

The <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> is the product of a company and its affiliates that have<br />

been in the publishing business for 84 years.<br />

Other publications edited for specialized markets and distributed worldwide include:<br />

Forest Products Export Directory • <strong>Hardwood</strong> Purchasing Handbook • Dimension & Wood<br />

Components Buyer’s Guide • Import/Export Wood Purchasing News • Imported Wood<br />

Purchasing Guide • Green Book’s <strong>Hardwood</strong> Marketing Directory • Green Book’s Softwood<br />

Marketing Directory • The Softwood Forest Products Buyer<br />

Paul J. Miller, Jr.................................................................................................................President<br />

Central States Editor<br />

Terry Miller ...........................................................................................Vice President – Sales Mgr.<br />

Northeast Editor<br />

Wayne Miller..............................................................................................................Vice President<br />

Canada & West Coast Editor<br />

Gary Miller .................................................................................................................Vice President<br />

Southeast Editor<br />

Barbara King ...........................................................................................................Travel Manager<br />

Virginia Sorensen....................................................................................................Finance Officer<br />

Sue Putnam.............................................................................................................................Editor<br />

Michelle Keller .......................................................................................................Associate Editor<br />

John Gray, Jr .................................................................................................................Art Director<br />

Walter Lee .....................................................................................................Associate Art Director<br />

Tammy Daugherty...........................................................................................Production Manager<br />

Charlene Jumper.................................................................................Green Book …Market Sales<br />

Lisa Carpenter.................................................................................................Circulation Manager<br />

Lexi Hardin ..........................................................................................Subscription & List Services<br />

ADVERTISING OFFICES:<br />

1235 Sycamore View, Memphis, TN 38134<br />

901-372-8280 FAX 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

e-mail addresses: ADVERTISING: tammy@millerpublishing.com<br />

EDITORIAL: editor@millerpublishing.com<br />

SUBSCRIPTIONS: circ@millerpublishing.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published monthly, except for<br />

two issues in December, for $55.00 per year and $65.00 (U.S. dollars) per year for Canada<br />

by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc., 1235 Sycamore View, Memphis, TN 38134.<br />

Periodicals Postage paid at Memphis, TN, and at additional mailing offices. POSTMASTER:<br />

Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, P.O. Box 34908, Memphis, TN<br />

38184. Publications mail agreement No. 40739074. Return undeliverable Canadian<br />

addresses to: P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

Website: www.gfhardwoods.com<br />

LUMBER FOR<br />

SALE<br />

FROM<br />

HAROLD WHITE<br />

LUMBER, INC.<br />

Manufacturers of Quality Appalachian <strong>Hardwood</strong> Lumber<br />

Harold White Lumber, Inc. features:<br />

* Quality bandsawn lumber<br />

* Excellent color and texture<br />

* 500,000 bf of kiln capacity<br />

* Planing mill facility<br />

* Moulding facility specializing in paneling, flooring,<br />

casing, doors and fingerjoint<br />

* Individual package tally and<br />

on-site container loading<br />

PROMPT WORLDWIDE SHIPMENTS<br />

CONTACT MIKE WHITE<br />

For Moulding and Millwork requests<br />

CONTACT LEE WHITE<br />

Harold White Lumber, Inc.<br />

2920 Flemingsburg Road • Morehead, KY 40351<br />

Phone (606) 784-7573 • Fax (606) 784-2624<br />

Email: mwhite@haroldwhitelumber.com<br />

MARCH/<strong>2011</strong> 3

HARDWOOD CALENDAR<br />

MARCH<br />

Appalachian Lumbermen’s Club, Meeting,<br />

Grandover Resort, Greensboro, N.C.<br />

Contact: 828-397-7481. <strong>March</strong> 10.<br />

<strong>Hardwood</strong> Manufacturers Association, <strong>2011</strong><br />

<strong>National</strong> Conference and Expo, Charleston,<br />

S.C. Contact: 412-244-0440. Mar. 14-16.<br />

APRIL<br />

Penn-York Lumbermen’s Club, Monthly<br />

Meeting, Host: Penn-Sylvan International,<br />

Seven Springs, Pa. Contact: 814-694-2311.<br />

April 18.<br />

NWFA, Annual Convention and Wood<br />

Flooring Expo, San Diego, Calif. Contact:<br />

Convention@NWFA.org. April 26-29.<br />

MAY<br />

Woodworking Industry Conference,<br />

Marriott Marco Island Resort & Spa, Marco<br />

Island, Fla. Contact: 800-438-4373. May 3-<br />

6.<br />

WHAT ARE YOU UP TO NOW?<br />

Expanding your facilities, adding personnel or equipment, holding a meeting or convention?<br />

The <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> would like to know so that we can publish your announcement.<br />

Send news items to:<br />

editor@nationalhardwoodmag.com<br />

Appalachian Lumbermen’s Club, Meeting,<br />

Ocean Reef Resort, Myrtle Beach, S.C.<br />

Contact: 828-397-7481. May 12-15.<br />

Penn-York Lumbermen’s Club, Monthly<br />

Meeting, Host: Babcock Lumber, Seven<br />

Springs, Pa. Contact: 814-694-2311. May 16.<br />

•<br />

www.bingamanlumber.com<br />

12 Species<br />

Logs<br />

Lumber<br />

Strips<br />

Dimensions<br />

Ripping<br />

Surfacing<br />

More Than 10 Million<br />

Board Feet of Inventory<br />

More Than 1 Million<br />

Board Feet of Kiln Capacity<br />

Consistent Quality<br />

Decades of Experience<br />

Commitment to Service<br />

Bingaman & Son Lumber, Inc.<br />

P.O. Box 247 Kreamer, PA 17833 USA<br />

570.374.1108 Fax: 570.374.5342<br />

E-mail: info@bingamanlumber.com<br />

4 <strong>Hardwood</strong>s Have Versatility

YOUR OPERATION NEEDS TO BE MORE EFFICIENT THAN EVER.<br />

YOU NEED TO CUT COSTS AND INCREASE PRODUCTIVITY.<br />

AND THERE’S NO ROOM FOR ERROR.<br />

Today’s business climate demands you<br />

get more done with less resources. With<br />

an order this tall, you’ll need Hyster lift<br />

trucks to fi ll it. Tough, durable and reliable,<br />

they derive their power to perform from<br />

80 years of engineering excellence.<br />

This economy has extended a clear<br />

challenge. And our reply is, bring it.<br />

11HST3498<br />

#1 IN TOUGH APPS WORLD-CLASS SERVICE FULL PRODUCT LINE INDUSTRIAL GRADE PARTS<br />

PURPOSE-BUILT RETURN ON INVESTMENT PROVEN HERITAGE STRONG DEALER NETWORK<br />

hysteramericas.com<br />

© <strong>2011</strong> Copyright Hyster Company. Hyster and are registered trademarks of Hyster Company.

Supplier news about sales, labor, prices, trends, expansions and inventories.<br />

SOUTHEAST LAKE STATES WEST COAST<br />

<strong>Hardwood</strong> lumber suppliers<br />

throughout the southeast region<br />

account for spotty weather conditions,<br />

which make logging activity<br />

difficult. “Our winter has been<br />

challenging to say the least,” a<br />

source in Arkansas noted.<br />

“We’ve had heavy rain and snow<br />

with cold then warm weather following.”<br />

As a result the supplier said<br />

green lumber production for his<br />

particular operation has been limited.<br />

“There are other, larger<br />

mills that have adequate log<br />

decks right now. We’re a small<br />

mill and weather conditions tend<br />

to hit our operation in a big way.”<br />

He commented that he expects<br />

competition for green lumber<br />

orders to intensify as we move<br />

into warmer temperatures in the<br />

spring. “At the end of 2010 we<br />

had a decrease in sawmill production<br />

due to weak market conditions,”<br />

he explained. “That<br />

short decrease eased oversupply<br />

issues. I think that competition<br />

for green orders will be intense<br />

for the second quarter and prices<br />

will come up on many species,<br />

particularly in the Common<br />

grades.”<br />

<strong>Hardwood</strong> lumber suppliers in<br />

the Lake States region report<br />

mixed market conditions. An<br />

Indiana source described business<br />

as “terrible,” while a contact<br />

in Michigan said sales activity<br />

for his operation is on an upward<br />

pace.<br />

“Activity in Indiana is slow<br />

right now,” the supplier said. “We<br />

don’t have a lot of inventory<br />

because we don’t see any<br />

demand.”<br />

Marketing Red and White Oak,<br />

Walnut, Ash, Cherry and Hard<br />

and Soft Maple, she said Red and<br />

White Oak and Walnut is her best<br />

moving species and Cherry is the<br />

slowest. She mentioned she was<br />

thankful for their export markets.<br />

“If we didn’t have our exports, I<br />

don’t know where we would be<br />

right now. Our domestic markets<br />

are not good right now but our<br />

exports have been very good,”<br />

she explained.<br />

As for transportation issues she<br />

said her customers have been<br />

having a difficult time. “Our customers<br />

are responsible for their<br />

own trucking and several of them<br />

have mentioned they are having<br />

trouble finding trucks to pick it<br />

Please turn to page 42 Please turn to page 42<br />

<strong>Hardwood</strong> lumber market activity<br />

on the West Coast is spotty.<br />

Suppliers in California report no<br />

real change in sales movement<br />

while Oregon sources describe<br />

continued improvement in overall<br />

business conditions<br />

“We are seeing a lot of positive<br />

signs for an increase in business in<br />

the coming months,” a <strong>Hardwood</strong><br />

supplier in Oregon stated. “Many<br />

of us made decisions in the previous<br />

two years that are benefiting<br />

us right now. Some of us had to<br />

cut our labor cost along with<br />

inventories. Others had to stop<br />

producing for a while and some<br />

never came back. All those decisions<br />

put us in the position we are<br />

in today. It’s been a slow recovery,<br />

but it is a recovery.<br />

“The overall attitude in our<br />

industry has seen a vast improvement<br />

in the past six months.<br />

Nobody expects an overnight<br />

overhaul, but we look for some<br />

increases by the third quarter,” he<br />

continued.<br />

The source, who handles most<br />

domestic <strong>Hardwood</strong> species and a<br />

few exotics, also mentioned most<br />

of his furniture, flooring and cabinet<br />

manufacturer customers report<br />

Please turn to page 54<br />

NORTHEAST<br />

Contacts in the northeast region<br />

account for varied degrees of<br />

<strong>Hardwood</strong> lumber market activity.<br />

A Pennsylvania <strong>Hardwood</strong> supplier<br />

said his local markets are<br />

stable. “I think we hit the bottom<br />

several months ago on the<br />

demand side. On the price side<br />

we’re still seeing some price<br />

reductions on low-grade lumber.<br />

The prices on our No. 2 and 3<br />

Common Red and White Oak<br />

have firmed up recently along<br />

with log prices.”<br />

Expecting a seasonal pick-up in<br />

activity he said, “Hopefully as we<br />

move into the spring months into<br />

the second quarter I think we’ll<br />

see a pick-up. Exports are going<br />

really strong. Globally we’ve<br />

seen an uptick in business overall.<br />

Domestically we’re starting<br />

to see orders pick up as well. It’s<br />

nothing that’s going to cause us<br />

to increase our production hours<br />

here, but none the less, it’s a<br />

pleasant surprise to see the orders<br />

increase from the domestic side.”<br />

In Connecticut, a source commented,<br />

“It’s tough sledding right<br />

now with no profit margins.”<br />

When asked to what he attrib-<br />

Please turn to page 55<br />

6 <strong>Hardwood</strong>s...A Renewable Resource

QUEBEC<br />

As 2010 came to a close, several executives at lumber companies<br />

offered a glimmer of hope going into the new year. They said, however,<br />

not to expect a dramatic turnaround. Most sectors within the<br />

industry, they added, are looking at a continuing slow economic<br />

recovery. It should be seen as a gradual occurrence; taking several<br />

quarters, rather than several months.<br />

One of the lessons they learned as a result of the U.S. housing<br />

crash, is the importance of developing a more diverse customer<br />

base. Several companies expanded their customer base not only to<br />

other Canadian provinces but to overseas markets as well, such as<br />

China, India and Europe. Others have successfully diversified or<br />

completely changed their product offerings.<br />

Heads of companies also forecasted that mills will run for the year<br />

rather than just parts of it, with shifts getting back on track, and<br />

companies that had closed indefinitely possibly restarting.<br />

Most sawmills reported adequate log supplies for current market<br />

conditions, but expressed concerns about the future, stating that<br />

with current lumber prices they were unable to replace the standing<br />

timber they were logging, and their log inventory was dropping<br />

fast. Most mills were trying to push down log and timber prices, but<br />

some raised their buying prices slightly to help keep supplies flowing.<br />

Component manufacturers provided some activity for Ash suppliers,<br />

as they bought large quantities of the species while demand<br />

from other sectors was at slower pace. Sales of Basswood had<br />

increased according to manufacturing contacts. Yellow Birch sales<br />

were still difficult to come by, but things usually pick up for this<br />

species by spring.<br />

However, on the furniture manufacturing side and the residential<br />

interior fittings, things have slowed somewhat. Business for sports<br />

flooring has been holding up, which was of great surprise to many<br />

in the industry.<br />

News from suppliers about prices,<br />

trends, sales and inventories.<br />

ONTARIO<br />

Many sawmills and wood products manufacturers resumed operations<br />

in mid- to late January, while others remained closed following<br />

the Christmas break, and staying closed for another month or<br />

two due to poor market conditions. Many sawmills were trying to<br />

push log prices lower, and were uncertain if they would have<br />

enough supply to build log decks for the spring thaw period. It was<br />

also reported that exports to most European markets stayed slow<br />

over the past few months.<br />

One moulding manufacturer stated he was using more Basswood<br />

because customers were looking for something cheaper than<br />

Cherry, Red Oak or Soft Maple. Hard Maple was not one of the<br />

best sellers of 2010, with its recent activity being rated as very<br />

slow. And, recent sales of Hard Maple were hard to come by, but<br />

there was a noted general softening of most grades during the<br />

month, with sales dropping slightly.<br />

One source contacted commented that No. 1 Common Soft Maple<br />

was being used as a substitute for Cherry, reducing the premium<br />

manufacturers were willing to pay for Sap/Better stock.<br />

There has been increased consumer interest in Red Oak, albeit the<br />

shift has been minor. Red Oak sales had been slower towards the<br />

end of 2010. White Oak prices continued to mildly soften under<br />

pressure from slowing exports. Walnut demand has increased<br />

again, making a sufficient supply of this species difficult to find.<br />

The species was reported as a consistent seller in the U.S. border<br />

states.<br />

According to industry forecasts, business conditions will be quite<br />

challenging for <strong>Hardwood</strong> strip flooring manufacturers during the<br />

first six months of <strong>2011</strong>, and some even say most likely for the<br />

whole year. This is caused by the slow housing recovery in the<br />

U.S., the high Canadian dollar, the slower new home construction<br />

and existing home sales being down as well in certain parts of<br />

Canada. Several flooring manufacturers took extended downtime,<br />

Please turn to page 56 Please turn to page 57<br />

MARCH/<strong>2011</strong> 7

Eye On Technology<br />

HYSTER SHOWCASES H300HD LIFT TRUCK<br />

AND INTRODUCES E30-40XN SERIES<br />

Hyster Co., based in Danville, Ill., recently showcased its H190-<br />

360HD heavy-duty pneumatic lift truck series at a World of Concrete<br />

Show.<br />

The H190-360HD series, with lifting capacities of 19,000 to 36,000<br />

lbs., features a standard low-emission Cummins QSB 6.7 Tier 3<br />

industrial diesel engine with turbocharger and intercooler.<br />

Hyster also unveiled its next generation of electric lift trucks recently.<br />

The new Hyster E30-40XN series delivers lifting capacities of<br />

3,000 to 4,000 lbs. and offers significant performance and versatility<br />

for a wide variety of material handling applications.<br />

“The E30-40XN series is one of the most operator-friendly ACpowered<br />

lift trucks in the world,” said Brett Schemerhorn, vice president<br />

of dealer sales, Hyster Company. “It sets a new standard in electric<br />

lift trucks by lowering overall operating costs and energy consumption<br />

while maximizing productivity. You can count on this workhorse<br />

to get the job done.”<br />

Hyster H300HD Lift Truck and Hyster E30-40XN series<br />

“This is a tough, smart and purpose-built lift truck,” Schemerhorn<br />

said. “It’s what you expect from Hyster.”<br />

Hyster Company is an operating division of NACCO Materials<br />

Handling Group, Inc. (NMHG), which employs approximately 4,500<br />

people worldwide. NMHG is headquartered in Cleveland, Ohio, and is<br />

8 <strong>Hardwood</strong>s Have Workability

Installation, Products and Services<br />

a wholly owned subsidiary of NACCO Industries, Inc. (NYSE:NC).<br />

Hyster and are registered trademarks of Hyster Company in the<br />

U.S. and other countries.<br />

MCDONOUGH MANUFACTURING REPORTS RECENT ACTIVITY<br />

Pike Lumber Co.’s new mill in Milan, Ind., started up the 1 st week<br />

of January. The new mill includes a McDonough 6-foot headrig as<br />

well as McDonough’s 7 th edger system. This edger system features<br />

McDonough’s ValueMax system, which allows an operator assisted<br />

visual defect upgrade of the optimizer’s solution and is Pike Lumber’s<br />

2 nd edger system of this kind.<br />

Rex Lumber Co.’s new tandem arbor lineal edger, for their new<br />

facility in Brookhaven, Miss., was tested in the shop in early January<br />

and shipped to the customer. This innovative machine design features<br />

two skewing saw boxes in one machine center. Sold to perform up to<br />

50 pieces per minute, once operating this will be one of, if not the,<br />

fastest edger in the world. This will be McDonough’s 8 th edger product<br />

since they started making edger’s just three years ago.<br />

For more information on McDonough Manufacturing’s custom line<br />

of sawmill machinery call 715-834-7755.<br />

PIERCE CONSTRUCTION ANNOUNCES ADDITIONS<br />

Pierce Construction and Machine of Petal, Mississippi announces<br />

two major additions to its already comprehensive line of Forest<br />

Products Equipment. Seeing a need for a small yet sturdy band mill<br />

head rig, Pierce purchased a proven design from Filer and Stowell.<br />

According to a Pierce representative, the new PCM High Air Strain<br />

48” Band Mill offers extreme flexibility. The same basic design can<br />

be used as a head rig, vertical resaw, or horizontal resaw. The representative<br />

also said using 18 – 20 gauge saws and kerfs as low as .080”<br />

will provide a mill maximum recovery from their logs.<br />

Coupled with the new PCM band mill head rig is the PCM Carriage.<br />

After an exhaustive research project Pierce took a clean sheet of paper<br />

and incorporated the best features it had found in current carriages.<br />

The PCM Carriage is offered in a set shaft and linear positioner models<br />

with 36”– 48” openings and two to five knees as required by the<br />

customer.<br />

•<br />

Many <strong>Hardwood</strong> suppliers’ footprints<br />

have come and gone, but one has stood<br />

bold and distinct for four generations<br />

in the Walnut business...<br />

Missouri-Pacific<br />

Lumber Co., Inc.<br />

Quality <strong>Hardwood</strong>s Since 1935<br />

694 DD Highway • Fayette, Missouri 65248-9635<br />

Phone: 800-279-7997 • Fax 660-248-2508<br />

www.mopaclumber.com<br />

MARCH/<strong>2011</strong> 9

NHLA News<br />

NHLA Offers A Multitude Of Educational Programs In <strong>2011</strong><br />

As <strong>2011</strong> begins, NHLA is unveiling plans for an<br />

exciting year to come. One particular area of interest<br />

is in educational programming. NHLA plans to host<br />

a multitude of educational programs during <strong>2011</strong>;<br />

from lumber grading and kiln drying short courses to<br />

educational seminars at this year's NHLA Annual<br />

Convention in Nashville.<br />

The spring and summer lineup includes two of<br />

NHLA's most favorably reviewed programs:<br />

Leadership, Management and Development<br />

Program and <strong>Hardwood</strong>s 101.<br />

The NHLA Leadership, Management and<br />

Development Program is divided into two sessions.<br />

The first of which will be held April 3-7 at NHLA<br />

headquarters in Memphis, Tenn., directed by Dr.<br />

Vaughn Grisham, a renowned leadership instructor.<br />

Session two will take place May 9-12 in<br />

Washington, D.C. lead by Deb Hawkinson,<br />

Executive Director of the <strong>Hardwood</strong> Federation and<br />

Grace Terpstra of Terpstra and Associates. The<br />

NHLA Leadership Program is limited to only 15<br />

participants. Interested individuals should contact<br />

NHLA Director of Education Chris Churchill immediately<br />

to secure their spot.<br />

by CHRIS CHURCHILL<br />

Director of Education<br />

<strong>National</strong> <strong>Hardwood</strong> Lumber Assoc.<br />

Memphis, Tenn.<br />

<strong>Hardwood</strong>s 101, is a four-day forest<br />

to market course that is truly an<br />

essential building block for a strong<br />

foundation within the <strong>Hardwood</strong><br />

industry. The program is perfect for office personnel<br />

or sales professionals who need to know more<br />

about the inner-workings of the business. The<br />

course will be held June 12-16 and offers a great<br />

line-up of speakers and instructors.<br />

We at NHLA continue in our pursuit to meet the<br />

needs of the <strong>Hardwood</strong> lumber industry and look<br />

forward to seeing industry members participating in<br />

all that NHLA has to offer in <strong>2011</strong>. For a complete<br />

list of all NHLA educational opportunities including<br />

the NHLA Inspector Training School please visit<br />

www.nhla.com or contact Chris Churchill at 901-<br />

399-7555 or c.churchill@nhla.com.<br />

•<br />

10 <strong>Hardwood</strong>s Have Resiliency

HMA & Solid <strong>Hardwood</strong><br />

Promotion<br />

Is There A Big Picture For American <strong>Hardwood</strong>s?<br />

Are you familiar with IBM Cognos’ advertisement “Business<br />

Intelligence is not an oxymoron?” (No, I’m not endorsing software or<br />

computer-based data analysis techniques.) The ad’s word usage was<br />

an attention-getter and it got me thinking about the meaning of these<br />

powerful words.<br />

• Business – “a commercial or industrial enterprise and the people<br />

who constitute it; the units that perform most of the economic activity<br />

in our economy”<br />

• Intelligence – “the ability to comprehend; to understand and profit<br />

from experience; aptitude in grasping truths, relationships, facts,<br />

meanings, etc.”<br />

• Oxymoron – “two words that conflict with each; words that do not<br />

agree with each other”<br />

For my money, “Business Intelligence” is not a contradiction of<br />

terms. (I’m siding with IBM on this one.) The words “business intelligence”<br />

do belong together. They compliment each other, significantly.<br />

For those of you that attended HMA’s recent <strong>National</strong> Conference<br />

and Expo in Charleston, I hope you will agree that there were more<br />

than a few great minds in that meeting room. And were it possible to<br />

tally the years of business experience on hand in that room, it would<br />

be a phenomenal number. For me, that’s business intelligence.<br />

In terms of the American <strong>Hardwood</strong> industry, I’m inspired when I<br />

think of HMA member businesses and the countless other <strong>Hardwood</strong>related<br />

businesses that have successfully “made their way” through<br />

by LINDA JOVANOVICH<br />

Executive Vice President<br />

<strong>Hardwood</strong> Manufacturers Association<br />

Pittsburgh, Pa.<br />

these difficult times. They did it by working “smart.” For me, that’s<br />

business intelligence.<br />

As an industry then, how should we be “connecting the dots” for<br />

the Big picture?<br />

From where I’m sitting - aligning projects with objectives; combining<br />

efforts, rather than duplicating them; putting aside all else,<br />

resolved to work for the industry’s greater good - will indeed connect<br />

the dots. For me, that’s business intelligence.<br />

If it takes a village to raise a child, it will be the unified voice of the<br />

American <strong>Hardwood</strong> industry that will make a difference in the marketplace.<br />

So as an industry, we need to think big! As an industry, we<br />

need to be aggressive! As an industry, we need to collaborate in order<br />

to impact change. For me, that’s business intelligence!<br />

The <strong>Hardwood</strong> Manufacturers Association is the only national<br />

<strong>Hardwood</strong> trade association with membership limited to U.S. sawmill<br />

and concentration yards. For more information about the work that<br />

we do for our membership, visit our websites at<br />

www.<strong>Hardwood</strong>Info.com; www.<strong>Hardwood</strong>Council.com, and<br />

www.HMAmembers.org or call (412) 244-0440.<br />

•<br />

12 <strong>Hardwood</strong>s...The All-Purpose Material

SFI<br />

SHELTER FOREST<br />

INTERNATIONAL<br />

CLIENT PROFILE<br />

CHRISTENSEN SHIPYARDS, LTD.<br />

VANCOUVER, WA. USA<br />

Shelter Forest International is a proud supply partner to the<br />

craftsmen of Christensen Shipyards. These craftsmen use<br />

TigerLITE panels for the interior cabinetry of their latest<br />

line of super yachts. TigerLITE sets a new standard in<br />

performance, with its high strength to weight ratio.<br />

SFI has set up an efcient, vertically integrated supply chain<br />

to design, produce and deliver TigerPLY to the worlds most<br />

demanding craftsmen.<br />

Photos by Stephen Cridland<br />

TigerLITE Specs:<br />

Available in Thickness size of:<br />

12mm x 4’ x 8‘ ..............32 lbs<br />

15mm x 4’ x 8‘ ..............39 lbs<br />

18mm x 4’ x 8‘ ..............46 lbs<br />

Available Face Species:<br />

White Birch, Natural Birch, White Maple, Alder,<br />

Okume, and now in Bamboo.<br />

Performance Data:<br />

AVG. MOR(Strength) =<br />

MOE (Stiffness) =<br />

Screw Withdrawal<br />

Peak Load =<br />

CARB Phase 2 Certied.<br />

5099psi<br />

497,000psi<br />

266 lbs<br />

www.tigerply.com<br />

Shelter Forest International<br />

Portland, Oregon U.S.A.<br />

877-505-0900<br />

www.shelterforest.com<br />

MARCH/<strong>2011</strong> 13

AHEC Update<br />

Cautious Optimism In Europe, But Still A Ways To Go...<br />

As <strong>2011</strong> gets underway, European <strong>Hardwood</strong> traders and end-users<br />

are reporting a clear positive trend in most markets, but, activity is<br />

still well below pre-recession levels, and there is concern that the real<br />

impact of the economic crisis, in terms of job losses and spending<br />

cuts, is yet to be fully felt in many markets. There is much uncertainty<br />

about the prospects for the coming year. A brief look at four of the<br />

most important markets for U.S. <strong>Hardwood</strong>s highlights some of the<br />

positive and negative aspects of the current conditions and shows that<br />

not all markets are doing better:<br />

Germany<br />

According to the trade press the German market for wood is<br />

improving. It appears that 2010 has been a better year for timber sales<br />

than many traders and importers had predicted. However, trading<br />

conditions are still far from ideal, but the year has ended with the<br />

<strong>Hardwood</strong> sector in reasonably good mood. German manufacturers<br />

and traders have seen the benefit of an improving domestic market,<br />

as their economy is doing better than most others in Europe. This also<br />

means it is a key target for export industries from other EU markets.<br />

For example, Germany is the most important export market for many<br />

high-end Italian furniture and kitchen producers.<br />

Construction is picking up again after a very slow 2009, although<br />

demand for new builds remains low but there is much more refurbishment<br />

and renovation going on as a result of consumers switching<br />

investment away from stocks and shares and back into property. This<br />

increased activity is helping demand for a range of <strong>Hardwood</strong> industries,<br />

especially the flooring sector. In terms of <strong>Hardwood</strong> demand,<br />

Oak is still number one and remains fashionable in all sectors. Beech<br />

demand continues to be poor and the same can be said of Maple and<br />

Cherry. The good news for U.S. <strong>Hardwood</strong> exporters is that German<br />

importers are important suppliers of <strong>Hardwood</strong> to manufacturers in<br />

central and eastern Europe, which helps explain why U.S. <strong>Hardwood</strong><br />

exports to Germany have been increasing even during a time of recession.<br />

On another positive note there are reports of increasing demand<br />

for Tulipwood.<br />

UK<br />

According to an article in the UK trade magazine, TTJ “the<br />

<strong>Hardwood</strong> business is hardly going to finish the year with a bang, but<br />

it’s not going out with a whimper either.” The article goes on to comment<br />

on reports from <strong>Hardwood</strong> traders that suggest that 2010 has<br />

been a satisfactory year overall as there has definitely been an<br />

improvement in trade from 2009. But business remains tough with<br />

importers and manufacturers continuing to take the short-term<br />

approach of buying little and often and for immediate delivery. With<br />

so much uncertainty still out there no one wants to hold more stock<br />

than is absolutely necessary but on the other hand, no wood, no sale!<br />

The joinery sector, so important to UK <strong>Hardwood</strong> consumption, is<br />

reasonably busy mainly related to renovation of existing buildings,<br />

by MICHAEL SNOW<br />

Executive Director<br />

American <strong>Hardwood</strong> Export Council<br />

Reston, Va.<br />

although recent reports suggest there may be a<br />

slight pick up in new build projects. There is<br />

also a bit more activity in the shop-fitting sector.<br />

Then of course there is the Olympics, this<br />

will only be applicable to the approved suppliers<br />

but many projects are now reaching the stage where <strong>Hardwood</strong> is<br />

required for interior fit outs. According to the TTJ report, the “top<br />

performing temperate species in 2010 were American White and<br />

European Oak.” American Walnut demand has also been good and<br />

Tulipwood demand has been strong in the joinery sector. However<br />

trade in Maple and Cherry is way down on a few years ago and Red<br />

Oak is still failing to make much headway and improve its market<br />

share. One key topic of conversation in the UK trade is Ash and the<br />

Emerald Ash Borer (EAB). UK has always been a good market for<br />

American Ash and demand has picked up again in recent years. Quite<br />

a few importers are reporting healthy sales of Ash but are concerned<br />

about supplies from the USA and some have had containers sent back<br />

because of non-compliance with current UK phyto-sanitary requirements.<br />

There are also reports of increased European Ash offers from<br />

suppliers trying to cash in on concerns about EAB. However, feedback<br />

suggests that the market generally prefers American Ash as it<br />

has a more consistent color and grain.<br />

There is also much discussion about the new illegal timber law and<br />

the implications for <strong>Hardwood</strong> importers. There is concern that there<br />

will be increased demand for third party certification to ensure legality<br />

and that this might restrict EU access for U.S. <strong>Hardwood</strong>s. The<br />

TTJ report suggested this might not be the case and quoted one<br />

importer as saying, “U.S. timber is widely perceived as legal and sustainable<br />

so I don’t think the EU legislation will be a barrier.” In<br />

response to whether there would be a shift more to European<br />

<strong>Hardwood</strong>s he concluded, “the Americans have a breadth of specification<br />

and, in key species, notably Oak, price in their favor.”<br />

Italy<br />

After a poor year for <strong>Hardwood</strong> sales in 2009, at least by Italian<br />

standards, 2010 has proved a better year. Importers and manufacturers<br />

are buying again having previously run their stocks right down.<br />

Of course we have not returned to pre-recession activity but there is<br />

a bit more optimism about than there was at the beginning of the year.<br />

Italy is the most important European market for U.S. <strong>Hardwood</strong> lumber<br />

sales and exports have improved this year. The latest import figures<br />

also confirm this trend with Italian imports of American<br />

Please turn to page 41<br />

14 <strong>Hardwood</strong>s Have Versatility

Component Trends<br />

WCMA To Update Cost Accounting Manual<br />

Given the current economic conditions and pressures of global competition,<br />

the <strong>Hardwood</strong> component industry is facing serious challenges<br />

to remain a profitable manufacturing sector of our economy.<br />

Wood component production is of critical importance to the<br />

<strong>Hardwood</strong> value chain as it provides a market for the higher value<br />

and more profitable <strong>Hardwood</strong> products derived from our nation’s<br />

forests. To assure continued viability of the component industry,<br />

manufacturers need to improve their knowledge and use of product<br />

costing methodologies to facilitate better business decisions.<br />

To meet this need, the Wood Component Manufacturers Association<br />

(WCMA) is conducting a value-added <strong>Hardwood</strong> products costing<br />

project in cooperation with the Wood Education & Resource Center<br />

(WERC). A big part of this project will be to update the WCMA’s<br />

existing “Cost Accounting Manual.” The manual will be revised in<br />

close cooperation with WCMA member companies and be of major<br />

benefit to all <strong>Hardwood</strong> dimension and component producers.<br />

Primary researchers for the project are Urs Buehlmann with the<br />

Department of Wood Science & Forest Products at Virginia Tech and<br />

Jan Wiedenbeck with the Forestry Sciences Laboratory of the U.S.<br />

Forest Service. This project will investigate current product costing<br />

practices of <strong>Hardwood</strong> component producers, then update those practices<br />

using state-of-the-art knowledge, and disseminate this information<br />

to the industry.<br />

Accurate product costing, i.e. the accounting for all expenses<br />

incurred when designing, manufacturing, selling, and servicing a<br />

product, is very important to the success of any business. Yet, it is<br />

one of the most difficult and poorly executed activities in many businesses,<br />

including the <strong>Hardwood</strong> industry. Better cost information has<br />

been identified as one of the most critical needs for success for<br />

dimension and component manufacturers. This is because component<br />

producers respond to many sales inquiries on a regular basis and<br />

need to give potential buyers fast and accurate quotes. With today’s<br />

competitive pressures, these quotes need to be as accurate as possible<br />

in order to gain the business while still generating a profit.<br />

Cost information has four major purposes:<br />

• To determine the cost of producing products<br />

• To aid in pricing products<br />

• To aid in measuring performance<br />

• To aid in decisions on purchasing new machinery or equipment<br />

Product costing, an activity under the umbrella of cost accounting,<br />

is a critical tool for manufacturers to know, with a high-degree of<br />

by STEVE LAWSER, CAE<br />

Executive Director<br />

Wood Component<br />

Manufacturers Assoc.<br />

Marietta, Ga.<br />

accuracy, the full cost profile of all products<br />

being manufactured. Only by knowing accurate<br />

and true product costs can businesses make<br />

decisions and transactions based on reliable<br />

information, thus enabling the optimization of<br />

their business success. The costing process begins with the receipt of<br />

green lumber, through drying, rough mill, finish mill, and shipping.<br />

The updated cost accounting manual will include sections on<br />

• Cost accounting principles<br />

• Different types of cost accounting systems<br />

• Accounting for and controlling material costs<br />

• Accounting for and controlling labor costs<br />

• Accounting for and controlling overhead costs<br />

• Pricing techniques<br />

• Management reports<br />

• Implementation and use of costing systems<br />

The manual will also include a “cost of doing business” section to<br />

develop a basis for comparing financial information, similar to Dun<br />

& Bradstreet. The WCMA conducts a “cost of doing business” study<br />

of their members biennially. This survey reports on 25 key financial<br />

operating ratios in the critical areas of profitability, financial management,<br />

asset management, inventory management, investment management,<br />

cost management, and worker productivity. Participants<br />

are then able to compare their own company’s performance to the<br />

industry standards and norms, allowing them to target areas for<br />

improvement within their own operations.<br />

The WCMA represents 130 manufacturers of dimension and wood<br />

component products for the cabinet, furniture, moulding & millwork,<br />

flooring, building products, and related decorative wood products<br />

industries. Member companies are located throughout the United<br />

States and Canada.<br />

For more information, contact the WCMA office at Tel: (770) 565-<br />

6660. Email: wcma@woodcomponents.org. Or visit the WCMA’s<br />

website at www.woodcomponents.org.<br />

•<br />

16 <strong>Hardwood</strong>s...A Renewable Resource

•<br />

Web Site – www.fitzweller.com<br />

Sales – Dana Fitzpatrick, Greg Fitzpatrick, Joe Snyder,<br />

J.C. Fritz, Jeremy Stitt<br />

Products – Balusters, Bed Posts, Bench Tops,<br />

Bendings, Blanks, Blocks & Cleats,<br />

Boxes/Crates/Container Panels, Brush Blocks, Bun<br />

Feet, Cabinet Doors, Cabinet Parts/Accessories,<br />

Carvings, Case Good Parts, Chair Parts, Columns,<br />

Component Part, Crib Parts/Slats, Cue Blanks,<br />

Custom Shapes, Cut Stock, Cutting Boards,<br />

Dimension Parts/Components, Doors, Door Parts,<br />

Dowels/Dowel Parts, Drawers and/or Drawer Parts,<br />

Finger Joint & Finger Joint Edge-Glued Parts,<br />

Flooring, Frame Parts, Furniture Parts/Components,<br />

Handles, Handrails, Industrial/Display Components,<br />

Jambs, Joining Biscuits, Kiln/Stacking Sticks, Legs,<br />

Lumber, Machined & Semi-Machined Components,<br />

Millwork, Moudings-Crown, Custom, Dentil, Embossed,<br />

Moulded & Tenoned Parts, Moulder Blanks, Mouldings,<br />

Musical Instrument Parts, Newels/Newel Posts,<br />

Pallets-Heat Treated, Paneling, Panels, Pedestals,<br />

Posts, Profiles (Decorative Parts), Pulls, Shelving,<br />

Specialty Items, Squares, Stair Treads, Stairs/Stair<br />

Parts, Stiles and/or Rail Stock, Store Fixture, Parts,<br />

Strip, Surveyor Stakes, Table Tops/Parts, Toy Parts,<br />

Trim, Turnings, Window Parts<br />

Species – Hard & Soft Maple, Cherry, Red & White<br />

Oak, Ash, Poplar, Walnut, Mahogany<br />

Machining Capabilities – Boring, Sanding, Tenoning,<br />

Moulding, CNC Machine Center<br />

Dry Kiln Cap. – 400,000 BF<br />

Indiana Dimension, Inc. (Page 15)<br />

1621 W. Market St., P.O. Box 568, Logansport, IN 46947<br />

Tel: (888)875-4434 Fax: (574)739-2818<br />

Web Site: www.indianadimension.com<br />

Sales – Jeremy Rentschler, Roy Rentschler<br />

Marketing Areas – International, <strong>National</strong><br />

Products - Mouldings, Cabinet Doors, Edge Glued<br />

Panels, S4S Products, <strong>Hardwood</strong> Dimension, Ready-to-<br />

Assemble Component Parts, Blanks, Cabinet Parts, Cut<br />

Stock, Doors, Door Parts, Furniture Parts, Moulded<br />

Parts<br />

Species - Northern & Appalachian <strong>Hardwood</strong>s,Poplar,<br />

Red Oak, Ash, Hickory, Hard Maple, Cherry, Walnut,<br />

Alder, White Soft Maple, White Oak<br />

Machining Capabilities – Sanding, Shaping, Tenoning,<br />

Water Based Finishing Capabilities<br />

Inter-Continental <strong>Hardwood</strong>s, Inc.<br />

(Inside Front Cover)<br />

6841 Malpass Corner Road<br />

P.O. Drawer 119, Currie, NC 28435<br />

Tel: (910)283-9960<br />

Fax: (910)283-9964<br />

Web Site - www.ichardwoods.com<br />

E-Mail – info@ichardwoods.com<br />

Sales –Jim Mills, Lenny Shibley, Fred Coffrin<br />

Marketing Areas – <strong>National</strong>, International<br />

Products - Squares, Dimension, Flooring, Machined<br />

Products, Lumber<br />

Species - Bloodwood, Lacewood, Jatoba, Iroko, Ipe,<br />

Goncalo Alves, Spanish Cedar, Morado, European<br />

Beech, Bubinga, Aniegre, Cumaru, Afrormosia, Teak,<br />

Zebrawood, Genuine Mahogany, Sipo Utile, African<br />

Mahogany, Santos Mahogany, Purpleheart, Peruvian<br />

Walnut, Sapele, Padauk, Mansonia, Makore, Wenge<br />

Machining Capabilities - Distribution/Concentration<br />

Yard, 5 Dry Kilns, 3 Warehouses, Pre-Dryers,<br />

Green/Dry Chain, Sawmills in Gabon, Congo – Ghana,<br />

Offices in Africa, Asia, Europe, South America<br />

Jay-Gee Wood Products Co., Inc. (Page 5)<br />

28W206 Commercial Avenue, Barrington, IL 60010<br />

Tel: (847)381-7200<br />

Fax: (847)381-0078<br />

Web Site – www.jaygeewood.com<br />

E-Mail – pfreund@jaygeewood.com<br />

Sales – Peter C. Freund<br />

Marketing Areas – International, <strong>National</strong><br />

Products - Cutting Boards, Blanks, Edge-Glued Panels,<br />

RTA Furniture Parts, Mouldings, Kitchen Items, Desk<br />

Accessories, Flooring, Laminated Squares, Clocks,<br />

Plaques, Flat Panels, Picture Frames<br />

Species - Ash, Walnut, Hard Maple, Soft Maple, Red<br />

Oak, Poplar, Cherry, All North American <strong>Hardwood</strong>s,<br />

Machining Capabilities - Full Finish Capabilities, Boring,<br />

Routing, Sanding, Shaping, Finishing, Cut-to-Size,<br />

Color & Grain Matching, CNC Machining<br />

Appalachian Lumber Co., Inc. (Page 6)<br />

5879 W. US Hwy 421, Wilkesboro, NC 28697<br />

Tel: (336) 973-7205/ (800) 298-3202<br />

Fax: (336) 973-8356<br />

Web Site – www.appalachianlumber.net<br />

Email – plankfloors@wilkes.net<br />

Sales – William Church, William Parsons, Scotty Roten<br />

Marketing Areas – <strong>National</strong><br />

Products – Edge-glued Panels, Stair Treads, Stair<br />

Risers, Architectural Mouldings, Custom Mouldings,<br />

Plank Flooring, Paneling, Moulder Blanks<br />

Species – Red Oak, White Oak, Hard Maple, Soft<br />

Maple, Poplar, Walnut, Ash, Cherry, Hickory, Eastern<br />

White Pine, Eastern Yellow Pine<br />

Machine Capabilities – Moulding, Sanding, Tenoning,<br />

Edge Gluing<br />

Dry Storage Cap. – 500,000 BF<br />

Begley Lumber Company, Inc. (Binder & Page 32)<br />

P.O. Box 2800, London, KY 40743<br />

Tel: (606)877-1228<br />

Fax: (606)877-1230<br />

www.begleylumber.com<br />

Email – jpatterson@beglumber.com<br />

Sales – Matt Begley, John Patterson<br />

Products - Mining, Flooring, Pallet Lumber, <strong>Hardwood</strong><br />

Mulch, High Grade Appalachian <strong>Hardwood</strong>s<br />

Species - Walnut, Red Oak, White Oak, Chestnut Oak,<br />

Hickory, Poplar, Beech, Soft Maple, Ash, Hard Maple<br />

Machining Capabilities - Hyden, KY - Bandmill,<br />

Automatic Band Mill, Bull-Edger, Trimmer, Debarker,<br />

Chipper, Anti-Stain and Bug Dip, Mulch Processing<br />

Dry Kiln Cap. – 740,000 BF<br />

Dry Storage Cap. – 3,000,000’<br />

Churchtown Woodcraft (Inside Back Cover)<br />

2095 Main St., Churchtown, PA 17555<br />

Tel: (717)445-7988<br />

Fax: (717)445-4872<br />

E-mail – churchtownwoodcraft@frontiernet.net<br />

Sales – Carl E. Zimmerman<br />

Marketing Areas – Regional<br />

Products - Jambs, Bench Tops, Drapery Rods,<br />

Drawers, Frame Parts, Furniture Parts/Components,<br />

Dimension Parts/Components, Industrail Components,<br />

Decking, Legs, Machined Components, Millwork,<br />

Moldings (Custom), Moulded Parts, Moulder Blanks,<br />

Handles, Chair Parts, Blanks, Blocks, Brush Blocks,<br />

Cabinet Doors, Cabinet Parts/Accessories, Doors,<br />

Case Good Parts, Profiles (Decorative Parts), Columns,<br />

Component Parts, Crib Parts/Slats, Custom Shapes,<br />

Cut Stock, Cutting Boards, Carvings, Toy Parts, Semi-<br />

Machined Components, Display Components, Musical<br />

Instrument Parts, Tenoned Parts, Posts, Rail Stock,<br />

Door Parts, Drawer Parts, Cleats, Trim, Window Parts,<br />

Table Tops/Parts, Store Fixture Parts, Stiles, Stairs,<br />

Stair Treads, Specialty Items, Shelving, Stair Parts,<br />

Brackets<br />

Species – All types of Wood – Domestic, Imports &<br />

Exports<br />

Machining Capabilities – CNC Routing Machine, Chop<br />

Saws, Wide Belt Sanders, Table Saw, Jointer, CNC<br />

Tenoner Machine, CNC Laser Engraver, Sign Carving,<br />

5,000 SF Plant.<br />

Custom Molding (Page 19)<br />

9061 E. 875 N., Odon, IN 47562<br />

Tel: (812)636-7110<br />

Fax: (812)636-0044<br />

Sales – John Graber<br />

Marketing Areas – Regional<br />

Products - Exterior Doors, Rope Moldings, Legs,<br />

Jambs, Handrails, Flooring, Components, Dimension<br />

Parts, Cut Stock, Bunfeet, Molder Blanks, Stairway<br />

Parts, Shelving, Interior Doors, Handles, Vinyl<br />

Windows, Turnings, Cabinet Parts, Furniture Parts,<br />

Blanks, Embossed <strong>Hardwood</strong> Moldings, <strong>Hardwood</strong><br />

Moldings, Dentil Moldings, Lumber, Stiles, Rail Stock,<br />

Strips, Surveyor Stakes, Millwork<br />

Species - White Oak, Poplar, Red Oak, Soft Maple,<br />

Hard Maple, Hickory, Cherry, Ash, Walnut<br />

Machining Capabilites - Molder, Embossing Machine,<br />

Rope Molder, Straight Line Ripsaw, Sanding, Shapers,<br />

Planers, Bandsaw, Resaw<br />

Dry Storage Cap. – 50,000 SF<br />

Fitzpatrick & Weller, Inc. (Page 9)<br />

12 Mill St., P. O. Box 490, Ellicottville, NY 14731<br />

Tel: (716)699-2393 Fax: (716)699-2893<br />

E-Mail – sales@fitzweller.com<br />

BUYERS!<br />

• •<br />

Lebanon Oak Flooring Co. LLC (Page 1)<br />

215 Taylor Ave., P.O. Box 669, Lebanon, KY 40033-0669<br />

Tel: (270)692-2128<br />

Fax: (270)692-2128<br />

Web Site – www.lebanonoak.com<br />

E-mail – lebanonoakflooring@windstream.net<br />

Sales – Robert L. Goodin, Richard T. Goodin<br />

Lumber Sales – Richard T. Goodin, Charles R. Goodin<br />

Marketing Areas – <strong>National</strong><br />

Products - Mouldings, Furniture, Kitchen Dimension<br />

Parts, Panels, Panels Edge- Glued, Stair Treads,<br />

Risers, Railing, Blanks, 5/16 sq. Edged Flooring, Strips<br />

& Plank, 3/8 x 1 1/2, 2”, 1/2 x 1 1/2, 2 1/4, 3/4 x 2 1/4,<br />

3 1/4, Drawer Sides, Tongue & Groove Flooring<br />

Species - Walnut, Red Oak, White Oak, Maple, Hickory,<br />

Cherry, Ash<br />

Machining Capabilities – Finger Jointing, Sanding<br />

Dry Kiln Cap. – 270,000’ (4 Kilns) per week<br />

Dry Storage Cap. – 5-600,000’<br />

MJB Wood Group, Inc. (Page 17)<br />

14780 SW Osprey Dr. #325, Beaverton, OR 97007<br />

Tel: (503)521-9663<br />

Fax: (503)521-9664<br />

Web Site – www.mjbwood.com<br />

E-Mail – bmonroe@mjbwood.com<br />

Sales – Brent Monroe<br />

Marketing Areas – <strong>National</strong>, International<br />

Products – Dimension, Plywood, MDF, Particleboard,<br />

Lumber/LVL, Panel Products, Mouldings & Millwork,<br />

Component Parts, Specialty Products<br />

Species – Domestic, Imports, Red Alder, PC Poplar<br />

Sitco Lumber Company (Page 23 & Back Cover)<br />

2050 Kestrel Avenue, DeSoto, TX 75115<br />

Tel: (972) 225-4283<br />

(800) 627-4826<br />

Fax: (972) 228-5987<br />

Web Site – www.sitco.com<br />

E-Mail- info@sitco.com sales@sitco.com<br />

Sales – Jess Fulcher – j.fulcher@sitco.com<br />

Steve McKeever – s.mckeever@sitco.com<br />

Pudge Shatzer – p.shatzer@sitco.com<br />

Bob Williams – b.williams@sitco.com<br />

Marc Barany – m.barany@sitcosa.com<br />

Jon Pappas – j.pappas@sitco.com<br />

Tony Jackson – t.jackson@sitco.com<br />

Kathy Mota – k.mota@sitco.com<br />

Marketing Areas – <strong>National</strong>, International<br />

Products – Lumber, Plywood, S2S, <strong>Hardwood</strong>s &<br />

Exotics<br />

Species – Domestic, Exotic & Imported <strong>Hardwood</strong>s<br />

Southland Wood Products, Inc. (Page 13)<br />

270 Newsome Rd., Wilsonville, AL 35186<br />

Tel: (205)669-1959<br />

Fax: (205)669-1959<br />

E-Mail – southlandwoodproducts@yahoo.com<br />

Sales – Tad Lidikay<br />

Marketing Areas – <strong>National</strong>, Regional<br />

Products - Cabinet Parts, Furniture, Rails, Dimension,<br />

Cut Stock, Blanks, Mouldings<br />

Species – Softwoods & <strong>Hardwood</strong>s<br />

Machining Capabilities - Profile Grinding Machine, 6-<br />

Head Wadkin Moulder, Straight Line Ripping, Gang<br />

Ripping, Moulding<br />

Dry Storage Cap. – 100,000 BF<br />

Stanley Woodworking, Inc. (Page 155)<br />

4113 White Top Rd., Middleburg, PA 17842<br />

Tel: (570)837-6434<br />

Fax: (570)837-1637<br />

Web Site – www.hardwoodparts.com<br />

E-Mail – contact.us@hardwoodparts.com<br />

Sales – Tom Fitzgerald<br />

Marketing Areas – <strong>National</strong><br />

Products – S4S Stock, Laminated Parts, Billiard & Pool<br />

Table Parts, Edge-glued Panels, Mouldings, Dimension,<br />

Squares, Stair Parts, Furniture Parts<br />

Species - Mahogany, Red Oak, White Oak, Cherry,<br />

Maples, Ash, Hickory, Walnut, Basswood, Poplar<br />

Machining Capabilities - Ripping, Chopsaws, Gluing,<br />

Moulding, Tenoning, Sanding, Finger Joint<br />

Dry Storage Cap. -1,000,000’<br />

Thompson Forest Products Intʼl (Page 2)<br />

24-B Battleground Court (27408)<br />

P. O. Box 9206, Greensboro, NC 27429<br />

Tel: (336)373-1117 Fax: (336)373-1119<br />

Web Site – www.thompsonforestproducts.com<br />

FOR MORE DETAILED SUPPLIER INFORMATION CHECK YOUR<br />

COPY OF THE DIMENSION & WOOD COMPONENTS BUYERʼS<br />

GUIDE. EACH FIRMʼS AD APPEARS ON THE PAGE NUMBER<br />

INDICATED IN “THE DIMENSION BOOK” ITSELF!<br />

TO LEARN MORE ABOUT OUR ANNUAL WOOD COMPONENT DIRECTORY, CONTACT US AT<br />

(901) 372-8280<br />

ITʼS THE ONLY WOOD TRADE PUBLICATION IN EXISTENCE THAT SOLELY PROMOTES THE DIMENSION AND WOOD COMPONENT INDUSTRY.<br />

E-Mail – billy@thompsonforestproducts.com<br />

bob@thompsonforestproducts.com<br />

Sales – Billy Thompson, Bob Thompson<br />

Marketing Areas – <strong>National</strong>, International<br />

Products - Dimension, Table Legs, Dowels, Bed Posts,<br />

CNC Shaped Parts, Components, Chair Assemblies,<br />

Mouldings, Edge Glued Panels, Turnings, Squares,<br />

Panels<br />

Species - Hickory, Ash, Maple, Beech, Gum, Pine, Oak,<br />

Poplar, Birch<br />

Machining Capabilites - Sanding, Tenoning, Moulding,<br />

Shaping, Routing, Boring<br />

Valley Line Wood Products (Page 21)<br />

2935 N. 500 W., Shipshewana, IN 46565<br />

Tel: (260)768-7807 Cell: (574)202-5614<br />

Fax: (260)768-3103<br />

E-Mail – valleyline@pcfreemail.com<br />

Sales – Danny Miller – danny.valleyline@gmail.com<br />

Marketing Areas – <strong>National</strong><br />

Products - Squares, Cabinet Parts, S4S <strong>Hardwood</strong><br />

Lumber, Trim, Edge Glued Panels, Strips, Drawers,<br />

Door Parts, Furniture, Blanks, Mouldings, Face Glued<br />

Panels, Drawer Parts, Stair Parts<br />

Species - Alder, Red Oak, White Oak, Hard Maple,<br />

Cherry, Elm, Ash, Poplar, Walnut, Others, Soft Maple<br />

Machining Capabilities - Sanding, Moulders, Edge<br />

Gluing Equipment, Chop Saws, Planer, Rip Saw,<br />

Optimizing Chop Saw, Shaping<br />

Wood Specialties de Mexico (Page 5)<br />

(Subsidiary of Jay-Gee Wood Products Company, Inc.)<br />

5811 East Dr. Ste. C, Laredo, TX 78041<br />

Tel: (847)381-7200<br />

Fax: (847)381-0078<br />

Web Site – www.jaygeewood.com<br />

E-Mail – pfreund@jaygeewood.com<br />

Sales – Peter C. Freund<br />

Marketing Areas – International, <strong>National</strong><br />

Products - Blanks, Flat Panels, Plaques, Clocks, Desk<br />

Accessories, Cutting Boards, Kitchen Items, Picture<br />

Frames, RTA Furniture, Edge Glued Panels<br />

Species - Hard Maple, Soft Maple, Red Oak, Ash,<br />

Poplar, Pine, Cherry, Walnut<br />

Machining Capabilities - Finishing, Boring, Routing,<br />

Sanding, Shaping<br />

Walnut Creek Planing Ltd. (Page 33)<br />

5778 State Route 515, Millersburg, OH 44654<br />

Tel: (330)893-3244<br />

(800)488-3244<br />

Fax: (330)893-2468<br />

E-Mail – sales@wcplaning.com<br />

Sales – Dwight C. Kratzer, Charles Kratzer<br />

Marketing Areas – International, <strong>National</strong><br />

Products - Balusters, S2S, Component Parts, Squares,<br />

Blanks, Component Parts, Surveyor Stakes, S4S, Door<br />

Stiles, Panels, Stair Treads, Custom Orders Welcome,<br />

Dowels, Chair Parts<br />

Species - Cherry, Maple, Beech, Soft Maple, Red Oak,<br />

Poplar<br />

Machining Capabilities – Sanding, Tenoning, Finger<br />

Jointing, Moulding, Ripping<br />

Yoder Lumber Company, Inc. (Page 210)<br />

4515 Berlin Twp. Rd. 367, Millersburg, OH 44654<br />

Tel: (330)893-3121<br />

Fax: (330)893-3031<br />

Web Site – www.yoderlumber.com<br />

E-Mail – sales@yoderlumber.com<br />

Sales – Paul Dow<br />

Marketing Areas – <strong>National</strong>, International<br />

Products – Moulded Parts, Semi-machined<br />

Components, Moulder Blanks, Machined Components,<br />

Panels, Laminated Squares, Squares, Balusters<br />

Species - Hard Maple, Cherry, Walnut, Soft Maple,<br />

White Oak, Beech, Poplar, Red Oak<br />

Machining Capabilities - PET, Sanding, Gluing, Ripping,<br />

S2S, Moulding<br />

Dry Kiln Cap. – 500,000 BF<br />

Dry Storage Cap. – 2,500,000 BF<br />

MARCH/<strong>2011</strong> 17

LEBANON OA<br />

OVER A CENTU<br />

1<br />

Lebanon, Ky.– It takes a lot to rattle the folks at Lebanon Oak<br />

Flooring Co., LLC. Even the current recession hasn’t been able to keep down<br />

a company that’s seen more than its fair share of economic ups and downs<br />

since being founded in the late-1800s.<br />

Where many firms across multiple industries have opted to stick their heads<br />

in the sand and wait out the downturn, Lebanon Oak Flooring is standing tall,<br />

finding new customers and exploring new product and service opportunities.<br />

18 <strong>Hardwood</strong>s Have Workability

K FLOORING<br />

RY OF SUCCESS, AND<br />

STILL GOING STRONG<br />

BY BRIDGET MCCREA<br />

2<br />

3<br />

4<br />

Credit the firm’s long history of success<br />

with insulating it from the negative economic<br />

conditions. A manufacturer of multiple<br />

wood products, including <strong>Hardwood</strong><br />

flooring (which makes up about half of<br />

the firm’s business), stair treads, risers,<br />

handrails, mouldings and edged glued<br />

panels, Lebanon Oak Flooring boasts a<br />

diversified product mix. The 60-employee<br />

company operates from 26 acres of land<br />

and 150,000 square feet of covered space<br />

here.<br />

Lebanon Oak Flooring uses about<br />

300,000 board feet of lumber every<br />

month, primarily 4/4 and 5/4 Red and<br />

White Oak, Maple, Hickory, Cherry,<br />

Ash and Walnut. Rick Goodin, plant<br />

manager, said the firm prefers<br />

Appalachian Oak, which it buys from<br />

sawmills and brokers in Kentucky,<br />

Southern Indiana, Southern Ohio,<br />

Tennessee, West Virginia and North<br />

Carolina. A sales team based in Lebanon<br />

and California sells to customers throughout<br />

North America.<br />

Rewind back to the late-1800s and<br />

Lebanon Oak Flooring got its start as a<br />

sawmill. In the early-1900s, it began man-<br />

Please turn to page 34<br />

1. Sixty employees manufacture Lebanon<br />

Oak’s products from a facility constructed on<br />

26 acres of land.<br />

2. Today, Lebanon Oak Flooring produces<br />

flooring in various thicknesses, including<br />

5/16-inch “top nail flooring,” which is<br />

becoming rare in the U.S.<br />

3. Lebanon Oak’s plant covers 150,000<br />

square feet of space.<br />

4. Other popular flooring sizes produced by<br />

Lebanon Oak Flooring include 3/4, 3/8, and<br />

1/2-inch tongue and groove.<br />

MARCH/<strong>2011</strong> 19

Neff Lumber<br />

Manufacturing Quality Appalachian <strong>Hardwood</strong>s<br />

BY GARY MILLER<br />

Broadway, Va.— From their six-foot band mill operation Neff Lumber Mills<br />

Inc., based here, manufactures green and kiln-dried Appalachian <strong>Hardwood</strong> lumber, heat<br />

treated pallets, skids, survey stakes, fenceboards, chips, mulch, sawdust and strips.<br />

Founded in 1928 by Newton A. Neff and Blair A. Neff, the company<br />

is family-owned and operated and produces approximately 5<br />

million board feet of Appalachian <strong>Hardwood</strong> lumber per year.<br />

Species offered by Neff Lumber include: Red and White Oak,<br />

Ash, Poplar, Cherry and steamed Black Walnut.<br />

In order to satisfy its broad customer base, Neff Lumber uses<br />

state-of-the-art sawmill equipment. Located in the Shenandoah<br />

Valley of Virginia, the 20-acre mill site includes SII dehumidification<br />

dry kilns; a computer operated linear positioner Corley carriage;<br />

a Fulghum debarker; a McDonough band saw; and a six-foot<br />

stacker. Rolling equipment includes Caterpillar forklifts.<br />

The company’s Appalachian <strong>Hardwood</strong> lumber is manufactured<br />

in thicknesses of 4/4 through 16/4. Neff mostly produces high<br />

grade <strong>Hardwood</strong>s and separates production according to customers’<br />

specifications for width and length.<br />

All of Neff’s lumber products are graded to <strong>National</strong> <strong>Hardwood</strong><br />

Lumber Association (NHLA) standards. Log Procurement<br />

Manager Mike Hoover said, “All of our kiln-dried lumber products<br />

are graded twice before they are prepared for shipment, once at the<br />

mill and again after kiln drying.” The firm’s dry kiln capacity is<br />

180,000 board foot per charge utilizing three dry kilns.<br />

Hoover continued, “Our Pendu gang saw has multiple uses. The<br />

industrial grade lumber goes into our Pendu system, which is used<br />

to cut up the lumber for pallets and stakes. The Pendu system is also<br />

used for ripping the lumber into strips in four through eight inch<br />

widths, which are made in six to 12 foot lengths.”<br />

Neff Lumber markets to a multitude of customers including different<br />

types of woodworking plants, <strong>Hardwood</strong> distribution/concentration<br />

lumberyards and exporters. Marijo Wood, sales manager for<br />

Neff Lumber Inc. said, “Our firm exports our lumber products to<br />

countries such as Denmark, Germany, England and China where it’s<br />

used for making <strong>Hardwood</strong> flooring, cabinets, window trim, and<br />

door frames.<br />

Our wood pallets are heat treated for export at 133 degrees,” Wood<br />

explained. “A hole is drilled in a piece of the material and we put a<br />

probe in to measure the temperature. When the temperature in our<br />

pallets reaches 133 degrees and stays at that temperature for about<br />

an hour, our pallets are ready for shipping to our various customers.”<br />

Please turn to page 40<br />

20 <strong>Hardwood</strong>s Have Resiliency

Several family members work at Neff Lumber Mills, Inc., including: Eric Hoover; Katie Hoover; Mike Hoover; Marijo Wood; Chris Hoover; and Matt Hoover.<br />

This is a view of Neff’s computer operated linear positioner Corley carriage and McDonough six-foot<br />

band saw.<br />

Danny Sherman grading the kiln dried lumber.<br />

The Caterpillar forklift operator is pushing the bundles of lumber into a container that will be shipped to one<br />

of Neff Lumber Mills, Inc.’s overseas customers.<br />

Neff Lumber Mills, Inc.’s large log yard has these main species<br />

of logs in inventory: Red and White Oak; Ash; Poplar,<br />

Cherry; and Walnut.<br />

MARCH/<strong>2011</strong> 21

Winter Wisconsin Meeting<br />

Enjoyed By LSLA Attendees<br />

BY WAYNE MILLER<br />

Green Bay, Wis.–<br />

Approximately 140 members and<br />

guests recently attended the <strong>2011</strong> winter<br />

meeting of the Lake States Lumber<br />

Association at the Radisson Hotel &<br />

Conference Center.<br />

Guest speakers for the meeting included<br />

Ross Bernstein, best-selling author of<br />

nearly 50 sports books, and Deb<br />

Hawkinson, executive director of the<br />

<strong>Hardwood</strong> Federation.<br />

Additionally, Travis Allen of the Wood<br />

Technology Center, based in Antigo,<br />

Wis., spoke of new technology in the<br />

wood industry and of the new 28,000<br />

square foot facility from which the center<br />

operates.<br />

Attendees also heard reports about the<br />

overall industry. Sources predicted that in<br />

Please turn to page 40<br />

LSLA Board of Directors are: (front row, from left) Gary Halpin, Riverside Sawmill, Muscoda, Wis.; Liz Russell,<br />

vice president, Stella-Jones Corp., Bangor, Wis.; Dave Sebastian, president, Big River Lumber Corp.,<br />

Trempealeau, Wis.; Scott Sawle, Rockbridge Sawmill Inc., Richland Center, Wis.; Will Borden, Quality<br />

<strong>Hardwood</strong>s Inc., Sunfield, Mich.; Mike Peterson, treasurer, Kretz Lumber Co. Inc., Antigo, Wis.; (back row,<br />