The New Spruce Forge Manual of Locksmithing: A Blacksmith’s Guide to Simple Lock Mechanisms

The New Spruce Forge Manual of Locksmithing: a Blacksmith’s Guide to Simple Lock Mechanisms is a totally revised and expanded version of the original work from 1999. This new hardcover edition, at 304 pages and with more than 800 color photos and illustrations, is more than double the size of the original manual. It is divided into two distinct sections: Technical Information - This section is a reference manual in itself that covers the specific tools and techniques needed to build all the parts for each lock, as well as providing the information needed to understand the assembly instructions outlined in the second section. The Locks: Patterns & Instructions - This section provides the plans and detailed instructions for each of the 14 lock projects in this new edition. The clear assembly instructions describe when and how to use the technical information provided in section one. The authors have maintained their original trademark style that relies on well-illustrated step-by-step instructions that guide you through the whole lock-making process. They have also kept their low-tech approach that demonstrates how to go about creating good work using only a handful of simple tools. Making blacksmith locks is an age-old skill the authors of this manual are helping to preserve by passing on their knowledge to this book’s readers. The New Spruce Forge Manual of Locksmithing is also an excellent introduction to benchwork, which is a useful skill for any blacksmith to acquire. This manual will become a valuable, trusted and often referred to sourcebook in your blacksmithing library. Hardcover, 304 pages, more than 800 photos and illustrations.

The New Spruce Forge Manual of Locksmithing: a Blacksmith’s Guide to Simple Lock Mechanisms is a totally revised and expanded version of the original work from 1999. This new hardcover edition, at 304 pages and with more than 800 color photos and illustrations, is more than double the size of the original manual.

It is divided into two distinct sections:

Technical Information - This section is a reference manual in itself that covers the specific tools and techniques needed to build all the parts for each lock, as well as providing the information needed to understand the assembly instructions outlined in the second section.

The Locks: Patterns & Instructions - This section provides the plans and detailed instructions for each of the 14 lock projects in this new edition. The clear assembly instructions describe when and how to use the technical information provided in section one.

The authors have maintained their original trademark style that relies on well-illustrated step-by-step instructions that guide you through the whole lock-making process. They have also kept their low-tech approach that demonstrates how to go about creating good work using only a handful of simple tools.

Making blacksmith locks is an age-old skill the authors of this manual are helping to preserve by passing on their knowledge to this book’s readers. The New Spruce Forge Manual of Locksmithing is also an excellent introduction to benchwork, which is a useful skill for any blacksmith to acquire. This manual will become a valuable, trusted and often referred to sourcebook in your blacksmithing library.

Hardcover, 304 pages, more than 800 photos and illustrations.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

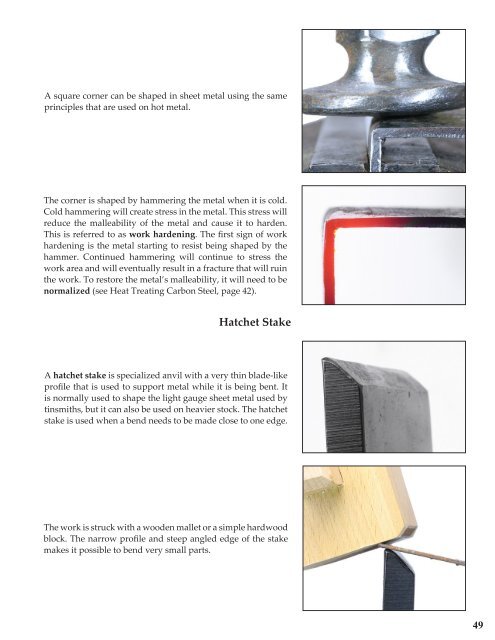

A square corner can be shaped in sheet metal using the same<br />

principles that are used on hot metal.<br />

<strong>The</strong> corner is shaped by hammering the metal when it is cold.<br />

Cold hammering will create stress in the metal. This stress will<br />

reduce the malleability <strong>of</strong> the metal and cause it <strong>to</strong> harden.<br />

This is referred <strong>to</strong> as work hardening. <strong>The</strong> first sign <strong>of</strong> work<br />

hardening is the metal starting <strong>to</strong> resist being shaped by the<br />

hammer. Continued hammering will continue <strong>to</strong> stress the<br />

work area and will eventually result in a fracture that will ruin<br />

the work. To res<strong>to</strong>re the metal’s malleability, it will need <strong>to</strong> be<br />

normalized (see Heat Treating Carbon Steel, page 42).<br />

Hatchet Stake<br />

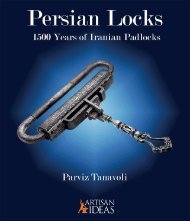

A hatchet stake is specialized anvil with a very thin blade-like<br />

pr<strong>of</strong>ile that is used <strong>to</strong> support metal while it is being bent. It<br />

is normally used <strong>to</strong> shape the light gauge sheet metal used by<br />

tinsmiths, but it can also be used on heavier s<strong>to</strong>ck. <strong>The</strong> hatchet<br />

stake is used when a bend needs <strong>to</strong> be made close <strong>to</strong> one edge.<br />

<strong>The</strong> work is struck with a wooden mallet or a simple hardwood<br />

block. <strong>The</strong> narrow pr<strong>of</strong>ile and steep angled edge <strong>of</strong> the stake<br />

makes it possible <strong>to</strong> bend very small parts.<br />

49