The New Spruce Forge Manual of Locksmithing: A Blacksmith’s Guide to Simple Lock Mechanisms

The New Spruce Forge Manual of Locksmithing: a Blacksmith’s Guide to Simple Lock Mechanisms is a totally revised and expanded version of the original work from 1999. This new hardcover edition, at 304 pages and with more than 800 color photos and illustrations, is more than double the size of the original manual. It is divided into two distinct sections: Technical Information - This section is a reference manual in itself that covers the specific tools and techniques needed to build all the parts for each lock, as well as providing the information needed to understand the assembly instructions outlined in the second section. The Locks: Patterns & Instructions - This section provides the plans and detailed instructions for each of the 14 lock projects in this new edition. The clear assembly instructions describe when and how to use the technical information provided in section one. The authors have maintained their original trademark style that relies on well-illustrated step-by-step instructions that guide you through the whole lock-making process. They have also kept their low-tech approach that demonstrates how to go about creating good work using only a handful of simple tools. Making blacksmith locks is an age-old skill the authors of this manual are helping to preserve by passing on their knowledge to this book’s readers. The New Spruce Forge Manual of Locksmithing is also an excellent introduction to benchwork, which is a useful skill for any blacksmith to acquire. This manual will become a valuable, trusted and often referred to sourcebook in your blacksmithing library. Hardcover, 304 pages, more than 800 photos and illustrations.

The New Spruce Forge Manual of Locksmithing: a Blacksmith’s Guide to Simple Lock Mechanisms is a totally revised and expanded version of the original work from 1999. This new hardcover edition, at 304 pages and with more than 800 color photos and illustrations, is more than double the size of the original manual.

It is divided into two distinct sections:

Technical Information - This section is a reference manual in itself that covers the specific tools and techniques needed to build all the parts for each lock, as well as providing the information needed to understand the assembly instructions outlined in the second section.

The Locks: Patterns & Instructions - This section provides the plans and detailed instructions for each of the 14 lock projects in this new edition. The clear assembly instructions describe when and how to use the technical information provided in section one.

The authors have maintained their original trademark style that relies on well-illustrated step-by-step instructions that guide you through the whole lock-making process. They have also kept their low-tech approach that demonstrates how to go about creating good work using only a handful of simple tools.

Making blacksmith locks is an age-old skill the authors of this manual are helping to preserve by passing on their knowledge to this book’s readers. The New Spruce Forge Manual of Locksmithing is also an excellent introduction to benchwork, which is a useful skill for any blacksmith to acquire. This manual will become a valuable, trusted and often referred to sourcebook in your blacksmithing library.

Hardcover, 304 pages, more than 800 photos and illustrations.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

This section will introduce you <strong>to</strong> all the basic metalworking skills that will allow you <strong>to</strong> turn raw materials<br />

in<strong>to</strong> <strong>to</strong>ols, hardware or mechanical parts.<br />

Terms Used in This Book<br />

<strong>The</strong> following is a list <strong>of</strong> terms and phrases used throughout the book. Unless specified in the accompanying<br />

text, their meaning is listed below.<br />

• Sheet metal. All sheet metal used is 16 gauge.<br />

• Steel, metal, s<strong>to</strong>ck, round bar (s<strong>to</strong>ck), square bar (s<strong>to</strong>ck), flat bar (s<strong>to</strong>ck), bar s<strong>to</strong>ck = mild steel unless it<br />

is specified as carbon steel.<br />

• Carbon steel. All carbon steel used is from recycled coil or leaf springs.<br />

• Any forging term, e.g.: drawing down, forge down <strong>to</strong> …, fuller, cross peen, implies a heat cycle even if it is<br />

not specified in the description.<br />

• Offsets, shoulder, step, transitions, refer <strong>to</strong> the way a forging changes from one cross section <strong>to</strong> another.<br />

• Rivets & tenons are forged cold unless specified.<br />

• Temper <strong>to</strong> a (color). Parts that need <strong>to</strong> be heat treated will usually have only the final temper color<br />

mentioned. However, it is unders<strong>to</strong>od that it has undergone a complete normalizing and hardening<br />

process before tempering.<br />

• <strong>Spruce</strong> <strong>Forge</strong> <strong>Manual</strong> = the first edition <strong>of</strong> <strong>The</strong> <strong>New</strong> <strong>Spruce</strong> <strong>Forge</strong> <strong>Manual</strong> <strong>of</strong> <strong><strong>Lock</strong>smithing</strong>.<br />

• <strong>The</strong> quenching oil we use is Canola oil (cooking oil). Recycled oils such as mo<strong>to</strong>r oil or hydraulic fluid<br />

can put out <strong>to</strong>xic fumes.<br />

Standard Tools<br />

In any trade, there are always <strong>to</strong>ols that make the difference between doing a job well and merely doing<br />

serviceable work. Making locks is no exception. This section describes some <strong>of</strong> the basic <strong>to</strong>ols that should be<br />

in every shop.<br />

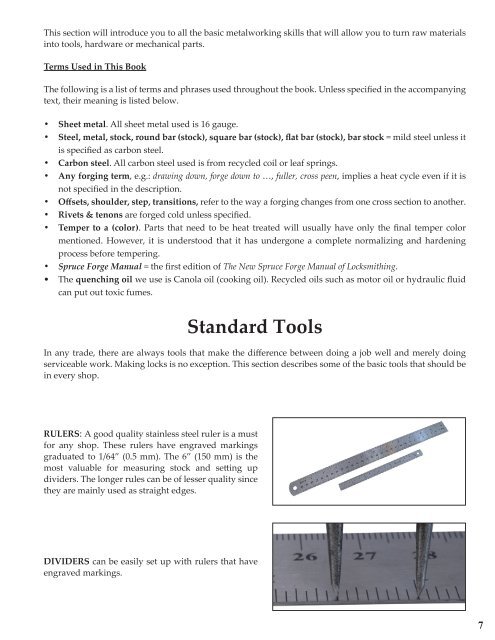

RULERS: A good quality stainless steel ruler is a must<br />

for any shop. <strong>The</strong>se rulers have engraved markings<br />

graduated <strong>to</strong> 1/64” (0.5 mm). <strong>The</strong> 6” (150 mm) is the<br />

most valuable for measuring s<strong>to</strong>ck and setting up<br />

dividers. <strong>The</strong> longer rules can be <strong>of</strong> lesser quality since<br />

they are mainly used as straight edges.<br />

DIVIDERS can be easily set up with rulers that have<br />

engraved markings.<br />

7