The New Spruce Forge Manual of Locksmithing: A Blacksmith’s Guide to Simple Lock Mechanisms

The New Spruce Forge Manual of Locksmithing: a Blacksmith’s Guide to Simple Lock Mechanisms is a totally revised and expanded version of the original work from 1999. This new hardcover edition, at 304 pages and with more than 800 color photos and illustrations, is more than double the size of the original manual. It is divided into two distinct sections: Technical Information - This section is a reference manual in itself that covers the specific tools and techniques needed to build all the parts for each lock, as well as providing the information needed to understand the assembly instructions outlined in the second section. The Locks: Patterns & Instructions - This section provides the plans and detailed instructions for each of the 14 lock projects in this new edition. The clear assembly instructions describe when and how to use the technical information provided in section one. The authors have maintained their original trademark style that relies on well-illustrated step-by-step instructions that guide you through the whole lock-making process. They have also kept their low-tech approach that demonstrates how to go about creating good work using only a handful of simple tools. Making blacksmith locks is an age-old skill the authors of this manual are helping to preserve by passing on their knowledge to this book’s readers. The New Spruce Forge Manual of Locksmithing is also an excellent introduction to benchwork, which is a useful skill for any blacksmith to acquire. This manual will become a valuable, trusted and often referred to sourcebook in your blacksmithing library. Hardcover, 304 pages, more than 800 photos and illustrations.

The New Spruce Forge Manual of Locksmithing: a Blacksmith’s Guide to Simple Lock Mechanisms is a totally revised and expanded version of the original work from 1999. This new hardcover edition, at 304 pages and with more than 800 color photos and illustrations, is more than double the size of the original manual.

It is divided into two distinct sections:

Technical Information - This section is a reference manual in itself that covers the specific tools and techniques needed to build all the parts for each lock, as well as providing the information needed to understand the assembly instructions outlined in the second section.

The Locks: Patterns & Instructions - This section provides the plans and detailed instructions for each of the 14 lock projects in this new edition. The clear assembly instructions describe when and how to use the technical information provided in section one.

The authors have maintained their original trademark style that relies on well-illustrated step-by-step instructions that guide you through the whole lock-making process. They have also kept their low-tech approach that demonstrates how to go about creating good work using only a handful of simple tools.

Making blacksmith locks is an age-old skill the authors of this manual are helping to preserve by passing on their knowledge to this book’s readers. The New Spruce Forge Manual of Locksmithing is also an excellent introduction to benchwork, which is a useful skill for any blacksmith to acquire. This manual will become a valuable, trusted and often referred to sourcebook in your blacksmithing library.

Hardcover, 304 pages, more than 800 photos and illustrations.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

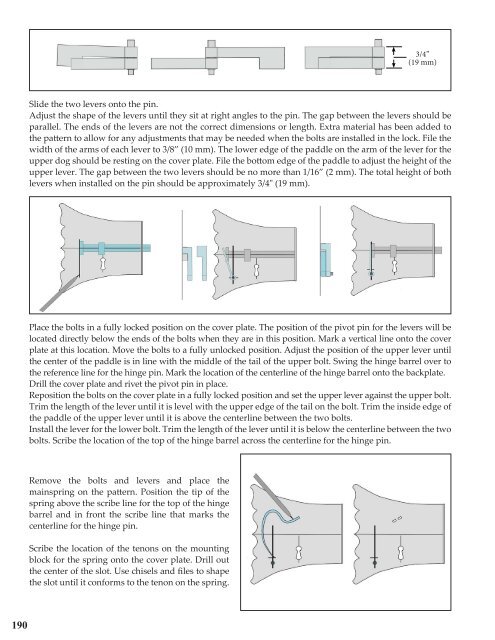

3/4”<br />

(19 mm)<br />

Slide the two levers on<strong>to</strong> the pin.<br />

Adjust the shape <strong>of</strong> the levers until they sit at right angles <strong>to</strong> the pin. <strong>The</strong> gap between the levers should be<br />

parallel. <strong>The</strong> ends <strong>of</strong> the levers are not the correct dimensions or length. Extra material has been added <strong>to</strong><br />

the pattern <strong>to</strong> allow for any adjustments that may be needed when the bolts are installed in the lock. File the<br />

width <strong>of</strong> the arms <strong>of</strong> each lever <strong>to</strong> 3/8” (10 mm). <strong>The</strong> lower edge <strong>of</strong> the paddle on the arm <strong>of</strong> the lever for the<br />

upper dog should be resting on the cover plate. File the bot<strong>to</strong>m edge <strong>of</strong> the paddle <strong>to</strong> adjust the height <strong>of</strong> the<br />

upper lever. <strong>The</strong> gap between the two levers should be no more than 1/16” (2 mm). <strong>The</strong> <strong>to</strong>tal height <strong>of</strong> both<br />

levers when installed on the pin should be approximately 3/4" (19 mm).<br />

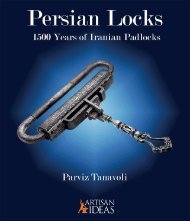

Place the bolts in a fully locked position on the cover plate. <strong>The</strong> position <strong>of</strong> the pivot pin for the levers will be<br />

located directly below the ends <strong>of</strong> the bolts when they are in this position. Mark a vertical line on<strong>to</strong> the cover<br />

plate at this location. Move the bolts <strong>to</strong> a fully unlocked position. Adjust the position <strong>of</strong> the upper lever until<br />

the center <strong>of</strong> the paddle is in line with the middle <strong>of</strong> the tail <strong>of</strong> the upper bolt. Swing the hinge barrel over <strong>to</strong><br />

the reference line for the hinge pin. Mark the location <strong>of</strong> the centerline <strong>of</strong> the hinge barrel on<strong>to</strong> the backplate.<br />

Drill the cover plate and rivet the pivot pin in place.<br />

Reposition the bolts on the cover plate in a fully locked position and set the upper lever against the upper bolt.<br />

Trim the length <strong>of</strong> the lever until it is level with the upper edge <strong>of</strong> the tail on the bolt. Trim the inside edge <strong>of</strong><br />

the paddle <strong>of</strong> the upper lever until it is above the centerline between the two bolts.<br />

Install the lever for the lower bolt. Trim the length <strong>of</strong> the lever until it is below the centerline between the two<br />

bolts. Scribe the location <strong>of</strong> the <strong>to</strong>p <strong>of</strong> the hinge barrel across the centerline for the hinge pin.<br />

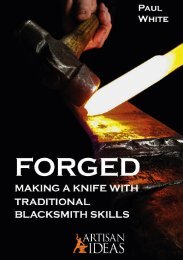

Remove the bolts and levers and place the<br />

mainspring on the pattern. Position the tip <strong>of</strong> the<br />

spring above the scribe line for the <strong>to</strong>p <strong>of</strong> the hinge<br />

barrel and in front the scribe line that marks the<br />

centerline for the hinge pin.<br />

Scribe the location <strong>of</strong> the tenons on the mounting<br />

block for the spring on<strong>to</strong> the cover plate. Drill out<br />

the center <strong>of</strong> the slot. Use chisels and files <strong>to</strong> shape<br />

the slot until it conforms <strong>to</strong> the tenon on the spring.<br />

190