Wood In Architecture Issue 1, 2023

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

STRUCTURAL ELEMENTS<br />

Structure (SVES), a flooring and wall<br />

module that aims to replace precast<br />

concrete floor slabs, built using<br />

homogeneous reconstituted timber<br />

(HRT) developed by Onewood.<br />

1<br />

WHAT ARE SVES AND<br />

RECONSTITUTED TIMBER?<br />

As its name suggests, the SVES has<br />

an eggcrate structure sandwiched in<br />

between two panels. The eggcrate<br />

structure is formed using a mould —<br />

made using a computerised numerical<br />

control (CNC) machine — that presses<br />

laminated layers of wood fibres into the<br />

eggcrate-like shape. There are two types<br />

of SVES: The wall module uses a single<br />

directional eggcrate structure that allows<br />

conduits and wirings to pass through the<br />

hollow space, and the flooring module<br />

uses a double directional structure that<br />

allows higher durability and strength.<br />

Currently, the SVES withstands 1.5kN<br />

of standing force. Furthermore, once<br />

fire retardant foam is pumped into the<br />

hollow spaces, the SVES can become a<br />

Class 0 component, which means it can<br />

be used in residential houses since it can<br />

slow the spread of fire.<br />

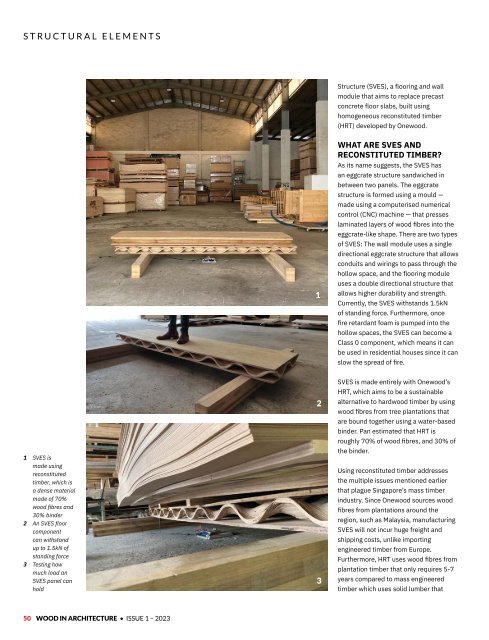

1 SVES is<br />

made using<br />

reconstituted<br />

timber, which is<br />

a dense material<br />

made of 70%<br />

wood fibres and<br />

30% binder<br />

2 An SVES floor<br />

component<br />

can withstand<br />

up to 1.5kN of<br />

standing force<br />

3 Testing how<br />

much load an<br />

SVES panel can<br />

hold<br />

2<br />

3<br />

SVES is made entirely with Onewood’s<br />

HRT, which aims to be a sustainable<br />

alternative to hardwood timber by using<br />

wood fibres from tree plantations that<br />

are bound together using a water-based<br />

binder. Pan estimated that HRT is<br />

roughly 70% of wood fibres, and 30% of<br />

the binder.<br />

Using reconstituted timber addresses<br />

the multiple issues mentioned earlier<br />

that plague Singapore’s mass timber<br />

industry. Since Onewood sources wood<br />

fibres from plantations around the<br />

region, such as Malaysia, manufacturing<br />

SVES will not incur huge freight and<br />

shipping costs, unlike importing<br />

engineered timber from Europe.<br />

Furthermore, HRT uses wood fibres from<br />

plantation timber that only requires 5-7<br />

years compared to mass engineered<br />

timber which uses solid lumber that<br />

50 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>