National Hardwood Magazine - October 2023

The October 2023 issue of National Hardwood Magazine features stories on E.F. San Juan, Classic American Hardwoods, Forest Products EXPO and more. The issue also includes industry news, business trends across the United States and Canada, and Who's Who in Hardwoods.

The October 2023 issue of National Hardwood Magazine features stories on E.F. San Juan, Classic American Hardwoods, Forest Products EXPO and more. The issue also includes industry news, business trends across the United States and Canada, and Who's Who in Hardwoods.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Devereaux Sawmill<br />

Specializes in:<br />

4/4 - 10/4<br />

White Hard Maple<br />

OCTOBER <strong>2023</strong><br />

4/4 - 8/4 Distribution<br />

yard quality, color<br />

sorted material in the<br />

following species:<br />

~Basswood<br />

~Cherry<br />

~Hickory<br />

~Soft Maple<br />

~Red Oak<br />

~White Oak<br />

~Walnut<br />

~Tulip Poplar<br />

Rift & Quartered<br />

~Red Oak<br />

~White Oak<br />

~Cherry<br />

~Walnut<br />

~Hard Maple<br />

Rustic Sorts<br />

Ripped to Width<br />

Mixed Loads Welcome<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 1

ONE SOFTWARE PARTNER<br />

FROM TIMBER TO CONSUMER<br />

TIMBER, LOGGING & LUMBER<br />

Handheld & desktop software<br />

DISTRIBUTION AND RETAIL<br />

Inventory and order management<br />

• Tigerton Lumber Co., providing<br />

quality hardwoods since 1887<br />

• 80-acre site; 95,000 sq. ft. under roof<br />

• 50,000 acres of our own forest lands<br />

in Wisconsin, USA<br />

• Sawing 18,400,000 board feet/year<br />

• 12 on-site KDS Kilns drying up to<br />

780,000 board feet/month<br />

• 1,500,000 board feet of inventory<br />

to meet your needs<br />

• We offer color, width & length sorts to<br />

your specifications behind our planer<br />

• Export prep capabilities<br />

Unparalleled in quality, rich consistent color and<br />

exceptionally tight grain make northern hardwoods the premier<br />

choice in wood flooring, kitchen cabinets, architectural millwork,<br />

moldings, door & stair parts.<br />

From the forests of northern Wisconsin and Michigan, where<br />

rich soil, cold winters and a short growing season combine<br />

to create the perfect atmosphere for producing hardwoods<br />

of unrivaled excellence and beauty … Tigerton Lumber brings<br />

you a full line of premium northern hardwoods.<br />

Available for export worldwide!<br />

Contact Mike Schulke today!<br />

715.535.2181<br />

mike@tigertonlumber.com<br />

www.tigertonlumber.com<br />

HARDWOOD END TALLIES<br />

Mobile app with A.I.<br />

VISIT DMSi.COM TO LEARN MORE<br />

2 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 1

Devereaux Sawmill<br />

Specializes in:<br />

4/4 - 10/4<br />

White Hard Maple<br />

4/4 - 8/4 Distribution<br />

yard quality, color<br />

sorted material in the<br />

following species:<br />

~Basswood<br />

~Cherry<br />

~Hickory<br />

~Soft Maple<br />

~Red Oak<br />

~White Oak<br />

~Walnut<br />

~Tulip Poplar<br />

Rift & Quartered<br />

~Red Oak<br />

~White Oak<br />

~Cherry<br />

~Walnut<br />

~Hard Maple<br />

Rustic Sorts<br />

Ripped to Width<br />

Mixed Loads Welcome<br />

Oct <strong>2023</strong> Deveroux Mag Cover.indd 1<br />

OCTOBER <strong>2023</strong><br />

8/30/23 1:31 PM<br />

Contents<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> OCTOBER <strong>2023</strong> Volume 97 No. 9<br />

Features & Industry Events<br />

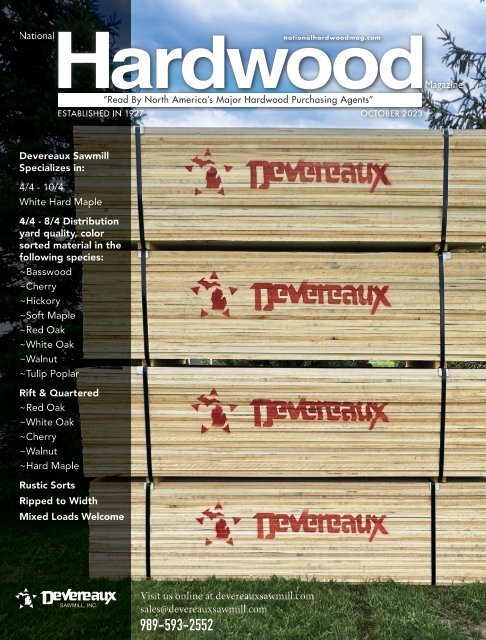

About The Cover<br />

DEVEREAUX SAWMILL<br />

Devereaux Sawmill is a quality focused<br />

hardwood lumber producer located in the<br />

heart of Michigan, a region long known for<br />

growing fine hardwood timber. From a humble<br />

beginning over 55 years ago, the Devereaux<br />

family has worked hard, reinvested and grown<br />

the company to be one of the largest in the<br />

northern state. The combination of sawmill<br />

operation and concentration yard provides the<br />

perfect scenario to procure a wide range of<br />

high quality hardwoods in almost every option<br />

imaginable. Striving to please the most discerning customer, Devereaux<br />

carries a vast inventory composed of all domestic species in thicknesses<br />

from 4/4-10/4. In addition to traditionally sawn lumber, Devereaux<br />

offers live sawn Rustic and Rift and Quarter Sawn. Finish Quality<br />

Surface and Ripped to Width or Pulled to Width services are also<br />

available. The focus at Devereaux is not on grade alone but also color,<br />

texture and any other requirement a customer might request. Because<br />

that’s the goal - to provide exactly what the customer needs when they<br />

need it.<br />

Check out the virtual pack link on our website to see a sample of what<br />

Devereaux has to offer. www.devereauxsawmill.com/virtual-packs/<br />

For prices and availability, please contact our sales staff at (989)593-<br />

2552 or email sales@devereauxsawmill.com.<br />

Save 10-25%<br />

on your monthly<br />

saw blade purchases<br />

by using Lubie ®<br />

Mention code NH23 to<br />

receive a $100 shipping<br />

credit on a new Lubie<br />

1000 spray system<br />

32<br />

36<br />

40<br />

E. F. San Juan Is Building A Legacy<br />

Classic American <strong>Hardwood</strong>s,<br />

Investing In Themselves, Their<br />

Customers And The Future<br />

Forest Products EXPO Brings Global<br />

Sawmill Industry Together In Nashville<br />

Departments<br />

52<br />

58<br />

Speakers Provide Important Industry<br />

Updates At WHA Annual Convention<br />

Penn-York Members Gather In Titusville<br />

36<br />

Founded in 1927 by: O.L. Miller – 1894-1963<br />

Publisher: Paul J. Miller – 1963-2010<br />

• Forest Products Export Directory • Imported Wood Purchasing Guide<br />

• Import/Export Wood Purchasing News • <strong>Hardwood</strong> Purchasing Handbook<br />

• Green Books’s <strong>Hardwood</strong> Marketing Directory<br />

• Green Books’s Softwood Marketing Directory<br />

• The Softwood Forest Products Buyer<br />

Paul J. Miller Jr. – President<br />

Terry Miller – Vice President<br />

Zach Miller – Sales Executive<br />

Chris Fehr – Sales Executive<br />

Sue Putnam – Editor<br />

Cadance Hanson - Staff Writer<br />

Dolores Buchanan - Who’s Who Coordinator<br />

Rachael Stokes – Graphic Artist<br />

Camille Campbell – Graphic Artist<br />

Tammy Daugherty – Production Manager<br />

Jennifer Trentman – Green Book Market Sales<br />

Lisa Carpenter – Circulation Manager<br />

Lexi Hardin – Subscription & List Services<br />

ADVERTISING OFFICES:<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134<br />

901-372-8280 FAX: 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

E-mail addresses:<br />

ADVERTISING: tammy@millerwoodtradepub.com<br />

EDITORIAL: editor@millerwoodtradepub.com<br />

SUBSCRIPTIONS: circ@millerwoodtradepub.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

Lubie® Saw Lubes for all species<br />

• Non-flammable<br />

• No odor<br />

• Biodegradable<br />

Installs on:<br />

• Head Rigs<br />

• Line Bars<br />

• Edgers<br />

• Pallet Saws<br />

• Gang Rips<br />

• Finger Jointers<br />

12 <strong>Hardwood</strong> Calendar<br />

14&16 U.S.A. Trends<br />

18 Canadian Trends<br />

20 Industry News<br />

22 HMA Update<br />

24 AHEC Report<br />

26 <strong>Hardwood</strong> Federation<br />

Info<br />

28 NAFF Bulletin<br />

30 NHLA: Why Knot...<br />

62 In Memoriam<br />

78 Who’s Who<br />

84 Classified Profit<br />

Opportunities<br />

87 Advertisers Index<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published<br />

monthly, except for two issues in December, for $55.00 per year and<br />

$65.00 (U.S. dollars) per year for Canada by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc.,<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134. Periodicals Postage paid at<br />

Memphis, TN, and at additional mailing offices.<br />

POSTMASTER: Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>,<br />

P.O. Box 34908, Memphis, TN 38184.<br />

Publications mail agreement No. 40739074.<br />

Return undeliverable Canadian addresses to:<br />

P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

The publisher reserves the right to accept or reject editorial<br />

content and Ads at the staff’s discretion.<br />

BIOLUBE<br />

The home of Lubie® saw lubricating systems and Lubie lubricants.<br />

www.biolube1.com • 260-414-9633<br />

email: sales@biolube1.com<br />

2 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 3

High Quality Northern <strong>Hardwood</strong>s<br />

Specializing High Quality in Green and Northern Kiln Dried Hard <strong>Hardwood</strong>s<br />

Maple and Birch<br />

- QUALITY AND SUSTAINABILITY SINCE 1882 -<br />

Specializing in Green and Kiln Dried Hard Maple and Birch<br />

- QUALITY AND SUSTA INABILITY Contact for more SINCE info: 1882 -<br />

Over 40 million FBM annual<br />

production of hardwood makes<br />

Over J.D. Irving, 40 million Limited FBM one of annual the<br />

largest producers in Eastern<br />

J.D.<br />

Canada<br />

Irving,<br />

and<br />

Limited<br />

New England.<br />

one of the<br />

largest As one of producers the top 5 private in Eastern<br />

Canada landowners and in New North England. America<br />

we ensure a long term quality<br />

As wood one supply. of the top 5 private<br />

landowners in North America<br />

we ensure a long term quality<br />

wood supply.<br />

Denis Dubé, Sales Manager<br />

506.992.9025<br />

dube.denis@jdirving.com<br />

Contact for more info:<br />

Jan Coburn, Sales Coordinator<br />

506.992.5360 Denis Dubé, Sales Manager<br />

coburn.jan@jdirving.com<br />

506.992.9025<br />

dube.denis@jdirving.com<br />

Eric Desjardins, Sales Representative<br />

506.401.0060<br />

Jonathan Connely, Sales Representave<br />

desjardins.eric@jdirving.com<br />

506.992.9024<br />

connely.jonathan@jdirving.com<br />

Jan Coburn, Sales Coordinator<br />

506.992.9040<br />

coburn.jan@jdirving.com<br />

Visit us online:<br />

Visit us online:<br />

4 www.JDIrvingLumber.com<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 5

<strong>Hardwood</strong> marketIng dIrectory<br />

online will give you access to over 6,000 buyers!<br />

Green Book’s<br />

<strong>Hardwood</strong><br />

Marketing<br />

directory<br />

“The World’s Leading Information Source on <strong>Hardwood</strong> Markets!”<br />

71st Edition/<strong>2023</strong><br />

The HARDWOOD PRODUCTS SALES GUIDE that tells you the species, grades, thicknesses and quantities of<br />

HARDWOOD LUMBER, IMPORTED WOODS, PLYWOOD, DIMENSION, ETC. purchased by woodworking<br />

plants in the United States and Canada.<br />

FEBRUARY COVERS <strong>2023</strong>.in d 1 1/16/23 10:40 AM<br />

You can get your share of this market<br />

quicker when these buyers know who you are<br />

and where you’re located!<br />

Advertising Sparks Sales!<br />

These are high grade & low grade<br />

buyers listed with their buying<br />

specifications including distribution/<br />

concentration yards that buy 100,000<br />

board feet or more throughout North<br />

America!<br />

LEASE ONLINE NOW<br />

FOR $2,100.00!<br />

Red Oak .........................2535<br />

White Oak .......................1692<br />

Poplar .............................1644<br />

Ash .................................788<br />

Hard Maple .....................1810<br />

Soft Maple ......................1451<br />

Walnut ............................1203<br />

Cherry .............................1673<br />

Imported Buyers<br />

Mahogany .................... 746<br />

Sapele ......................... 221<br />

Teak ............................. 125<br />

These are the BIG THREE species in our Imported section<br />

of the <strong>Hardwood</strong> Marketing Directory online!<br />

The <strong>Hardwood</strong> Marketing Directory has 68 years of research helping firms discover new<br />

buying opportunities and contains all North American species and also Imported Woods.<br />

GREEN BOOK, INC.<br />

P.O. Box 34908 Memphis, TN 38184<br />

Phone: (901) 372-8280 FAX: (901) 373-6180<br />

www.millerwoodtradepub.com E-mail: greenbook@millerwoodtradepub.com<br />

6 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 7

Our industry has<br />

stories to tell.<br />

MERIDIEN HARDWOODS OF PA., INC.<br />

“Everything You’ll Ever Need From The Forest”<br />

We’re telling them.<br />

45,000 ft. steamer loaded with 4/4<br />

Face & Better Walnut<br />

4/4 Face & Better Walnut ready<br />

for shipment<br />

n 18 Acre Concentration Yard<br />

n 2 Trim Lines (50 Sorts)<br />

n Straight Line Ripping and S2S Facilities<br />

n We Offer Export Preparations, Container Loading,<br />

Mixed Species & Thicknesses<br />

n Custom Walnut Steaming Available<br />

n 800,000ʹ Dry Storage • Dry Kiln Capacity 250,000'<br />

n All KD Lumber End Pictured and Tallied via TallyExpress<br />

BUILD YOUR OWN LOAD<br />

Contribute Now to Build Your World<br />

Contribute Now to Build Your World<br />

Contribute Now to Build Your World<br />

The Real American <strong>Hardwood</strong> Coalition has launched its Build Your World<br />

campaign<br />

The Real American<br />

in partnership<br />

<strong>Hardwood</strong><br />

with Magnolia<br />

Coalition<br />

Network.<br />

has launched<br />

The ads<br />

its Build<br />

are inspiring<br />

Your World<br />

national<br />

audience<br />

campaign The Real American<br />

by<br />

in partnership <strong>Hardwood</strong><br />

educating them<br />

with<br />

on<br />

Magnolia Coalition<br />

the benefits<br />

Network. has launched<br />

of Real<br />

The<br />

American<br />

ads its Build are inspiring Your World<br />

<strong>Hardwood</strong>®<br />

a national<br />

products.<br />

audience campaign by in partnership educating them with on Magnolia the benefits Network. of Real The American ads are inspiring <strong>Hardwood</strong>® a national products.<br />

audience by educating them on the benefits of Real American <strong>Hardwood</strong>® products.<br />

The campaign was made possible thanks to voluntary contributions from the<br />

hardwood<br />

The campaign<br />

industry.<br />

was made<br />

Your continued<br />

possible thanks<br />

support<br />

to<br />

is<br />

voluntary<br />

critical to<br />

contributions<br />

advance the<br />

from<br />

initiative<br />

the<br />

and<br />

reclaim<br />

hardwood The campaign<br />

market<br />

industry. was made<br />

share<br />

Your<br />

for the<br />

continued possible thanks<br />

benefit<br />

support to<br />

of all industry<br />

is voluntary critical<br />

stakeholders.<br />

to contributions advance the from initiative the and<br />

reclaim hardwood market industry. share Your for the continued benefit support of all industry is critical stakeholders.<br />

to advance the initiative and<br />

reclaim market share for the benefit of all industry stakeholders.<br />

Help Build Your World. Learn more about the RAHC’s promotion efforts,<br />

see<br />

Help Build<br />

list of<br />

Your<br />

supporters,<br />

World. Learn<br />

and make<br />

more about<br />

voluntary,<br />

the RAHC’s<br />

tax-deductible<br />

promotion<br />

contribution<br />

efforts,<br />

at<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

see Help a Build list of Your supporters, World. Learn and make more a about voluntary, the RAHC’s<br />

or scan<br />

tax-deductible promotion<br />

the QR code.<br />

contribution efforts, at<br />

RealAmerican<strong>Hardwood</strong>.com/industry see a list of supporters, and make a voluntary, or scan tax-deductible the QR code. contribution at<br />

RealAmerican<strong>Hardwood</strong>.com/industry or scan the QR code.<br />

8 OCTOBER Real <strong>2023</strong> American n NATIONAL <strong>Hardwood</strong> HARDWOOD is a registered MAGAZINE trademark, and Build Your World is a trademark of the Real American RealAmerican<strong>Hardwood</strong>.com/industry<br />

Coalition.<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 9<br />

Real American <strong>Hardwood</strong> is a registered trademark, and Build Your World is a trademark of the Real American <strong>Hardwood</strong> Coalition.<br />

Real American <strong>Hardwood</strong> is a registered trademark, and Build Your World is a trademark of the Real American <strong>Hardwood</strong> Coalition.<br />

Shade-Dri ® Protection<br />

Brandon Ferman<br />

Office: 814-563-4614<br />

Cell: 814-688-6691<br />

Email: brandonferman@hotmail.com<br />

Dan Ferman<br />

Office: 814-563-4614<br />

Michael Songer<br />

Office: 814-486-1711<br />

Cell: 814-594-0827<br />

Email: mjs@zitomedia.net<br />

(800) 780-3187 FAX: (800) 292-5773<br />

Jeff Childs<br />

Office: 740-392-7727<br />

Cell: 740-398-3474<br />

Email: jeffchilds7@yahoo.com<br />

Website: www.meridienpa.com • Email: meridien@penn.com<br />

Yard Address: Old Pittsfield Rd., Pittsfield, PA 16340

GET A KICK.<br />

Introducing...<br />

VisionTally set a new standard for end-tally accuracy, automatically scanning<br />

and measuring bundles from both ends at once with unmatched laser accuracy.<br />

Now, the next generation VisionTallyHD pushes that standard even further:<br />

• Higher accuracy<br />

• Reduced labor<br />

• Increased reliability<br />

• Faster scanning under 1 minute<br />

• Enhanced wane detection<br />

• Improved dark lumber scanning<br />

C<br />

M<br />

Y<br />

CM<br />

The VisionTally Difference<br />

• The most accurate, automated,<br />

complete end-tally solution available<br />

MY<br />

CY<br />

CMY<br />

K<br />

• The only end-tally device that measures<br />

actual width and actual length<br />

• The only device certified by the NHLA<br />

Tally Machine Certification Program<br />

• World-wide reputation for accuracy that<br />

gives you confidence and builds trust with<br />

your customers<br />

Improving your bottom line is our goal line. That’s why we quote fairly and<br />

deliver hardwood to maximize quality and help minimize waste. We also offer<br />

mixed species and sizing with J.I.T. shipments to reduce inventory costs.<br />

And those are just two of our plays.<br />

CALL COLE TODAY. WE’RE ON YOUR TEAM.<br />

HARDWOOD LUMBER FOR ALL YOUR HARDWOOD NEEDS<br />

Quotes: 800-536-3151 • Export: 574-753-3151 • colehardwood.com<br />

<br />

Industrial Vision Systems, Inc.<br />

Sawmill MD<br />

sales@visiontally.com<br />

SawmillMD@mindspring.com<br />

(215) 393-5300<br />

Mike Ballard (850) 974-1195<br />

10 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE www.VisionTally.com<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 11

HARDWOOD CALENDAR<br />

<strong>October</strong><br />

<strong>National</strong> <strong>Hardwood</strong> Lumber Association, Omni Louisville Hotel, Louisville, KY. www.nhla.com.<br />

Oct. 4-6.<br />

Funding<br />

For your Neck of the Woods<br />

High Point Market, High Point, NC. www.highpointmarket.org. Oct. 14-18.<br />

Railway Tie Association, Westin Buckhead, Atlanta, GA. www.rta.org. Oct. 16-19.<br />

November<br />

Appalachian Lumbermen’s Club, Carnegie Hotel, Johnson City, TN. www.lumberclub.org. Nov. 14. n<br />

Big corporate banks can<br />

feel distant and disconnected.<br />

We offer lending solutions that are<br />

a little closer to home. Farm Credit<br />

Mid-America understands the<br />

unique financial neds of the forest<br />

products and timber business, and<br />

we are right here in your backyard.<br />

LET’S CONNECT.<br />

Get started at:<br />

FCMA.COM/FOREST-PRODUCTS<br />

Loans subject to credit approval. Additional terms and<br />

conditions may apply. Farm Credit Mid-America is an<br />

equal opportunity lender.<br />

12 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry

U.S.A. TRENDS<br />

Supplier news about<br />

sales, labor, prices, trends,<br />

expansions and inventories<br />

INDUSTRIES<br />

CONTROLS<br />

LAKE STATES<br />

In the Lake States region, sources from different states<br />

are sharing a generally positive outlook on their market<br />

conditions. Notably, two sources have mentioned that the<br />

Red Oak market is showing stronger performance in their<br />

region.<br />

In Indiana, a lumber saleswoman mentioned that her<br />

inventory is growing, but she’s seeing certain wood species<br />

gain popularity, notably in her higher-grade products.<br />

“Our inventory is a little heavy right now, but some<br />

things are changing. I am seeing a lot of export orders<br />

come in for Red Oak. I am optimistic that is going to take<br />

a dent out of our inventory and help get some of those<br />

prices back up. Hard Maple has changed some and I am<br />

sold out of it in 4/4 Select and Better and have been able<br />

to get its price back up here recently. White Oak is su-<br />

NORTHEAST<br />

In the Northeast region, various sources from different<br />

states provided insights into the market conditions.<br />

While one source described the situation as slightly<br />

improving and steady, another source commented that<br />

their markets were starting to cool down. Additionally,<br />

consistent with other sources, White Oak sales have<br />

been performing good at the time of this writing.<br />

In Pennsylvania a <strong>Hardwood</strong> saleswoman said that<br />

her markets slowed down overall but she is having<br />

some success with the demand for her White Oak.<br />

“It seems to have gotten a little slower. I think it is the<br />

typical end of the summer slowdown especially with the<br />

heat we have all had. The White Oak has been a bright<br />

spot for us and is helping us get through these tough<br />

times. White Oak prices seem to be staying stable and<br />

CLEEREMAN LUMBER COMPANY 1930’s CLEEREMAN INDUSTRIES 1955 CLEEREMAN CONTROLS 2019<br />

TODAY<br />

For optimal efficiency. . .<br />

knows what a sawmill needs:<br />

Now, TWO ENTITIES TO SERVE YOU BETTER!<br />

Please turn to page 64 Please turn to page 65<br />

Rustic Wood Products cuts the finest Appalachian <strong>Hardwood</strong><br />

lumber, cants and railroad ties for our customers, and those<br />

in need of these wood products.<br />

Call us today at (573) 547-8227 when we can be of service!<br />

Some of the key products we make, and services we offer, are:<br />

• green, air dried and/or kiln dried lumber in 4/4 and 5/4 thicknesses<br />

• S2S Now Available<br />

• species like Red Oak, Walnut, White Oak, Hard Maple, Ash, Poplar,<br />

Cottonwood and Cherry, in 6-16 foot lengths<br />

• all lumber is band sawn and double end trimmed<br />

• 250,000 board feet per charge of dry kiln capacity<br />

• 300,000 board feet of kiln dried inventory<br />

In Business<br />

• 1,000,000 board feet of air dried inventory under cover<br />

Harvesting the finest <strong>Hardwood</strong>s since 1972<br />

• our own trucks and logging crew<br />

6347 Highway 51 • Perryville, MO 63775<br />

Phone: (573) 547-8227 • Fax: (573) 547-2288<br />

CELEBRATING<br />

Website: www.rwpinc.net<br />

Sales: Kurt Rehagen<br />

CLEEREMAN The most trusted name in carriages<br />

n Over 1240 Carriages sold<br />

n Lowest cost of ownership<br />

n All parts in stock and reasonably priced<br />

n In-house engineering department<br />

n Everything from single piece equipment to<br />

turn-key mills<br />

14 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry Sales<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 15<br />

STEFAN DRACOBLY<br />

President Of<br />

Controls<br />

PAUL CLEEREMAN<br />

VP Cleereman<br />

Industries & Controls<br />

DAN TOOKE<br />

Senior Optimization<br />

& Controls Engineer<br />

CLEEREMAN the newest name in sawmill controls and optimization<br />

n Simple easy to use touch<br />

screen with additional<br />

tactile buttons<br />

n Remote access for<br />

troubleshooting<br />

n No custom electrical<br />

hardware, all parts are<br />

off-the-shelf components<br />

n Industry JoeScan<br />

JS-50X6 Heads<br />

n 3D data used for<br />

opening the log and<br />

estimating the back of<br />

log profile<br />

n Realistic views of the log<br />

n Sure Grip Joystick<br />

handles<br />

n Operational statistics and<br />

reports<br />

n Over 170 systems sold<br />

Cleereman Industries<br />

and Cleereman Controls<br />

715-674-2700<br />

www.cleereman.com<br />

info@cleereman.com

For over a century, Corley has been<br />

the most trusted name in the industry.<br />

SOUTHEAST<br />

In the Southeast region, various <strong>Hardwood</strong> representatives<br />

from different states are observing the lumber<br />

market to be “Okay”, with White Oak showing notable<br />

strength according to one source.<br />

A <strong>Hardwood</strong> sales representative in Tennessee<br />

reported that his domestic sales of White Oak are<br />

performing well, but he’s encountering difficulties in his<br />

export markets.<br />

“We are doing okay. Certain species are moving better<br />

than others. White Oak has picked up substantially here<br />

recently. It had a little slow down for a while but that is<br />

trending up and we are selling more White Oak now. I<br />

would describe everything else as ranging from okay to<br />

a little below average. Most of our sales right now are<br />

domestic. Pretty much every export market has been<br />

WEST COAST<br />

On the West Coast, different sources provided insights<br />

into their market situations. Two sources mentioned average<br />

and steady business conditions, while another<br />

noted some inconsistency in their markets.<br />

In Washington, a <strong>Hardwood</strong> salesman reported that<br />

his markets show inconsistency, with one week being<br />

different from the next.<br />

“Things are very sporadic. We will have a week or two<br />

where we are busy then will have a few weeks where it<br />

is just dead. There is no consistency in my markets right<br />

now that’s for sure. White Oak is doing good for us but<br />

it’s not just all the White Oak that has some demand.<br />

For us it seems like a lot of people just want wider width<br />

lumber. They are not looking for the random and the narrow<br />

boards. A lot of these higher end flooring people are<br />

Please turn to page 66 Please turn to page 67<br />

BINGAMANLUMBER.COM<br />

PO Box 247, Kreamer, PA 17833<br />

☎ 570.374.1108 | 570.374.5341<br />

Since Since 1905, 1905, our our family-owned business business has has been been built built upon upon a a reputation for for quality, quality, integrity, integrity, and and<br />

old-fashioned business business ethics. ethics. Today, Today, our our partnership with with Lewis LewisControls brings brings you you the the best best in in<br />

equipment and and optimization software. software. From From turnkey turnkey sawmills sawmills to to individual individual machine machine centers centers and and<br />

retrofits, retrofits, we’re we’re committed to to providing providing maximum maximum returns returns on on your your investment—year after after year. year.<br />

Our Our experienced professionals can can help help you you realize realize a a profit profit potential potential you you may may have have never never thought thought<br />

possible. possible. Call Call us us today today or or visit visit our our website website to to discover discover what what lumbermen have have known known for for over over<br />

100 100 years. years. Wood Wood is is Wonderful...and who who knows knows that that better better than than we we do? do?<br />

www.corleymfg.com<br />

www.lewiscontrols.com<br />

P.O. P.O. Box Box 471 471 | Chattanooga, Tennessee Tennessee 37401 37401 | tel: tel: 423-698-0284 | fax: fax: 423-622-3258<br />

16 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 17

ONTARIO<br />

CANADIAN TRENDS<br />

News from suppliers about prices, trends, sales and inventories<br />

QUEBEC<br />

WE’RE CONFIDENT OUR<br />

AI FOR HARDWOOD IS #1<br />

As we head into fall, businesses are looking at ways of<br />

building inventories for later in the season and into early<br />

winter. With the Labor Day weekend behind us, it is business<br />

as usual. However, with lower production levels<br />

over the summer months, businesses are finding it challenging<br />

McMinnville, to get TN the stocks they need. Sawmill contacts<br />

Glen Thompson and Tommy Stiles, A.W. Stiles Contractors Inc.,<br />

say they have not produced excessive amounts of most<br />

species. whose topic Some was expressed Growing the concern Global Pie. of having adequate<br />

supplies At this moving year’s IHLA through Convention, winter. Prices multiple appear networking to be stabilizing,<br />

opportunities<br />

and<br />

were<br />

with<br />

offered,<br />

the forest<br />

and the<br />

fires<br />

association’s<br />

that raged<br />

board<br />

throughout<br />

of directors<br />

held a business session. The 2017 board president<br />

the summer across the country, it is felt there may be<br />

shortages for some species in the coming months.<br />

for IHLA is Shaun Cook, of C.C. Cook & Son Lumber Co., of<br />

Ash inventories are reported as low for kiln-dried lumber<br />

although demand is somewhat steady on domestic<br />

Reelsville, IN. Tom Oilar of Cole <strong>Hardwood</strong>, located in Logansport,<br />

and international<br />

IN, is the<br />

markets.<br />

2017 1st<br />

Depending<br />

vice president<br />

on<br />

and<br />

areas<br />

Brett<br />

contact-<br />

Franklin,<br />

of Tri-State Timber LLC of Bloomington, IN is the IHLA<br />

<strong>October</strong> is upon us and the fall season is in full swing<br />

for those in the <strong>Hardwood</strong> industry. Planning and stocking<br />

up on supplies to see businesses through the fall and<br />

early winter are under way. Some are finding it challenging<br />

to get the lumber they need as competition is rather<br />

Lumber stiff at Co., this Lexington, time, and KY; as and sawmills Tom Johel, try U-C to Coatings build-up LLC their<br />

Matt Taylor, U-C Coatings LLC, Buffalo, NY; Damon Graf, DR Graf<br />

production schedules and ensure a good mix of species<br />

according 2nd vice president. to demand.<br />

In Additionally, the U.S. border in conjunction states, Ash with demand the IHLA is meeting, low due the to<br />

the<br />

Fellowship<br />

Emerald<br />

of<br />

Ash<br />

Christian<br />

Borer<br />

Lumbermen<br />

decimating<br />

held<br />

these<br />

a brief<br />

trees,<br />

meeting.<br />

and also<br />

most of the Ash produced is being exported overseas.<br />

IHLA is a non-profit trade organization comprised of sawmills,<br />

wholesale brokers, equipment vendors, secondary<br />

Demand for this species, along with overall sawmill production,<br />

noted contacts, has been down this past year.<br />

manufacturers, loggers and landowners, among others in<br />

Demand for the regionally important Hard Maple is<br />

also<br />

the industry.<br />

down at this time, although gap between supply<br />

Learn more at www.ihla.org. n<br />

Please turn to page 68 Please turn to page 70<br />

Additional photos on next page<br />

NORTHERN & APPALACHIAN HARDWOODS<br />

NORTHERN & APPALACHIAN HARDWOODS<br />

[ WWW.SIMONLUSSIER.COM ]<br />

[ WWW.SIMONLUSSIER.COM]<br />

MATHIEU LUSSIER - Export Sales Manager m2lussier@simonlussier.com<br />

450.435.6591 - 16 BOUL. DE LA SEIGNEURIE EST, BLAINVILLE, QC CANADA J7C 3V5<br />

18 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE APRIL 2017 n NATIONAL RealAmerican<strong>Hardwood</strong>.com/industry<br />

HARDWOOD MAGAZINE 51<br />

[ WWW.SIMONLUSSIER.COM ]<br />

NORTHERN & APPALACHIAN HARDWOODS<br />

TAKE YOUR PRODUCTION TO A SUPERIOR LEVEL.<br />

THE ONLY AI MODELS TRULY DEVELOPED<br />

USING HARDWOOD!<br />

• Proper defect detection despite dirt, spots, and chain marks<br />

• No bottlenecks at wood grading<br />

• Consistent production quality<br />

• Labor-saving costs<br />

VISIT US AT THE NHLA ANNUAL CONVENTION!<br />

<strong>October</strong> 4-6, Louisville, KY<br />

Booth 105<br />

SEE OUR AI-POWERED SCANNERS<br />

IN ACTION!<br />

Call now to find out how you can<br />

maximize your production value.<br />

450-435-2121 | info@bidgroup.ca

INDUSTRY NEWS<br />

AN UPDATE COVERING THE LATEST NEWS ABOUT<br />

HARDWOOD SUPPLIERS/VENDORS<br />

Bingaman & Son Lumber Promote<br />

Domestic Lumber Salesman<br />

Bingaman & Son Lumber (BSL), located in Kreamer,<br />

PA, recently promoted Kevin Kiesinger to domestic lumber<br />

salesman. BSL has a concentration yard in Clarendon,<br />

PA, as well as three sawmills located in Mill Hall, St.<br />

Marys, and Nicktown, PA. BSL sells <strong>Hardwood</strong> products<br />

in both domestic and export markets.<br />

BSL produces 45 million board<br />

feet of lumber annually. Their<br />

products range from 4/4 through<br />

12/4 in green and kiln-dried lumber.<br />

They offer kiln-dried lumber<br />

in rough and<br />

surfaced, as<br />

well as R1E<br />

and R2E. Kevin Kiesinger<br />

They also offer<br />

Thermally Modified lumber products.<br />

Kiesinger has worked for BSL for<br />

10 years, where he first started in<br />

the lumber production yard. He then<br />

went on to lumber inspector training,<br />

followed by several years as transportation<br />

logistics director before being<br />

promoted to domestic sales.<br />

Kiesinger graduated from Midd-<br />

West High School, in Middleburg,<br />

PA.<br />

Kiesinger enjoys spending time<br />

with his family, bowling, and playing<br />

slow pitch softball. He has been married<br />

to Danielle Kiesinger for nine<br />

years and has one daughter, Hailey<br />

Kiesinger.<br />

BSL is a member of Keystone<br />

Wood Products Association, Pennsylvania<br />

Forest Products Association,<br />

Forest Stewardship Council,<br />

<strong>Hardwood</strong> Manufacturers Association,<br />

<strong>National</strong> <strong>Hardwood</strong> Lumber Association<br />

and Sustainable Forestry<br />

Initiative.<br />

For more information, call 570-<br />

374-1108 ext. 1166, email kkiesing<br />

er@bingamanlumber.com or visit<br />

www.bingamanlumber.com.<br />

NWH Acquires Post<br />

<strong>Hardwood</strong>s<br />

NWH, headquartered in Frisco,<br />

TX, a premier manufacturer and<br />

supplier of <strong>Hardwood</strong> lumber to<br />

North America, Europe and Asia,<br />

proudly announced the recent<br />

acquisition of Post <strong>Hardwood</strong>s, a<br />

long-standing <strong>Hardwood</strong> supplier<br />

and manufacturer based in Hamilton,<br />

MI.<br />

Post <strong>Hardwood</strong>s, established<br />

in 1980 by brothers Bob and Junior<br />

Post, is<br />

renowned<br />

for delivering<br />

Nathan Jeppson high-quality<br />

and diverse<br />

<strong>Hardwood</strong> lumber and logs from<br />

the Glacial region to their customers.<br />

The company’s 13,500-squarefoot<br />

sawmill facility is situated on<br />

20-acres, approximately 35 miles<br />

south of Grand Rapids.<br />

“The acquisition of Post <strong>Hardwood</strong>s<br />

marks an important milestone<br />

in NWH’s growth,” said Nathan<br />

Jeppson, CEO of NWH. “Their<br />

impressive operations complement<br />

our customer commitment to reinforce<br />

and expand our position as a<br />

global leader in <strong>Hardwood</strong> supply.”<br />

Post <strong>Hardwood</strong>s’ extensive log<br />

sales business enhances NWH’s<br />

product range and flexibility, offering<br />

customers greater variety. The acquisition<br />

also gives NWH access to<br />

an array of sought-after Glacial species.<br />

Additionally, Post <strong>Hardwood</strong>s’<br />

deep experience in sawing high<br />

quality lumber and superior sourcing<br />

capabilities broadens NWH’s supply<br />

chain.<br />

“We’re delighted to be joining the<br />

NWH family,” said Bob Post, CEO of<br />

Post <strong>Hardwood</strong>s. “This move paves<br />

the way for exciting new opportunities<br />

for our team while allowing us to<br />

uphold our unwavering commitment<br />

to quality. Together, we can better<br />

serve our customers and lead the<br />

<strong>Hardwood</strong> industry into the future.”<br />

“As a long-term customer and<br />

partner of Post <strong>Hardwood</strong>s, we<br />

have first-hand experience with<br />

the exceptional quality their mill delivers,” continued<br />

Jeppson. “This acquisition underscores the strength of<br />

our long-standing relationship and mutual commitment<br />

to industry excellence.”<br />

Founded in 1967, NWH has committed to streamlin-<br />

Please turn to page 75<br />

20 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 21

HMA UPDATE<br />

Join Us To Strategize!<br />

I’ve already received several 2024<br />

calendars – I’m guessing you have, too – so<br />

I’d like you to take a moment and ‘ink’ in the<br />

dates of HMA’s 2024 <strong>National</strong> Conference<br />

and Expo. Our 2 ½ day event will take<br />

place March 25-27, at the Charleston<br />

Place Hotel, Charleston, South Carolina.<br />

And all <strong>Hardwood</strong> industry stakeholders<br />

are welcome to join us. Here are a few of<br />

the up-front details.<br />

Our 2024 Conference theme is “Pathways to<br />

Success.” And for the past several months I’ve been<br />

lining up speakers and presentations regarding issues of<br />

importance to the HMA membership, and the <strong>Hardwood</strong><br />

industry at large – leadership, technology, trends, the<br />

economy – and also presenters that offer ‘pathways’ to<br />

overcome those issues. It’s going to be an interesting<br />

gathering, and your participation will make it even more<br />

so. Join us to strategize.<br />

To whet your appetite a little more, here is some<br />

information about our historic and inspiring venue:<br />

•The Charleston Place Hotel - located in<br />

the heart of Charleston’s historic district,<br />

“stirs the senses and lives forever in the<br />

minds and souls of all who gather at this<br />

independent, iconic landmark. It captivates<br />

the heart and imagination. And through<br />

sumptuous accommodations, delicious food<br />

and drink, restorative wellness services,<br />

and warm, generous hospitality, the Hotel is<br />

redefining the legendary service, experiences - and the<br />

city - with a renewed passion, purpose and intention.”<br />

(charlestonplace.com)<br />

For more about NatCon ’24, visit HMAmembers.<br />

org. There you’ll find program specifics, registration,<br />

sponsorship opportunities, hotel information, a listing of<br />

participating industry suppliers, and more.<br />

And remember, All <strong>Hardwood</strong> lumber producers<br />

and processors are welcome to attend. You read that<br />

correctly. HMA’s <strong>National</strong> Conference and Expo is open<br />

to all industry stakeholders. You have my personal<br />

invitation to join us to strategize in Charleston. n<br />

C<br />

M<br />

Y<br />

CM<br />

MY<br />

CY<br />

CMY<br />

K<br />

•Charleston - “Whether you’re looking to immerse<br />

yourself in a rich coastal culture, hop on a tour, splash<br />

in the waves, or find your bliss in a spa oasis, you’ll find<br />

what you are looking for in Charleston. Cobblestone<br />

streets and historic landmarks; high-end restaurants<br />

or festive, dockside oyster roasts; outdoor cafes and<br />

the best grits you’ll ever have, Charleston is waiting to<br />

welcome You!” (www.charlestoncvb.com)<br />

2024 HMA <strong>National</strong><br />

Conference and Expo<br />

Monday–Wednesday, March 25–27<br />

The Charleston Place | 205 Meeting St | Charleston, SC 29401<br />

BY LINDA JOVANOVICH,<br />

EXECUTIVE VICE PRESIDENT,<br />

HARDWOOD MANUFACTURERS ASSOCIATION,<br />

PITTSBURGH, PA<br />

412-244-0440<br />

WWW.HMAMEMBERS.ORG<br />

Please turn to page 57<br />

Conference Highlights<br />

Economic Predictions: Hits & Misses<br />

Raw Material Trends<br />

Federal Funding Programs<br />

Industry Updates<br />

Panel on Generational Communications<br />

Sawmilling in the Pacific Northwest<br />

Register online at HMAmembers.org<br />

412.244.0440 | info@hardwood.org | HMAmembers.org<br />

Williamsburg Place, Suite 108 | Warrendale, PA 15086<br />

22 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 23

AHEC REPORT<br />

WE ARE GRAF BROTHERS<br />

The world’s largest manufacturer of<br />

rift & quarter sawn white oak products<br />

With Technical Support From AHEC, Groundbreaking Mass<br />

Timber Office Building In London Makes Extensive Use Of<br />

Thermally Modified American Tulipwood<br />

The seven-story structure, commissioned<br />

by commercial real estate firm The Office<br />

Group (TOG), lays out a roadmap for the<br />

office environment of today. In fact, architects<br />

Waugh Thistleton (WTA) say it demonstrates<br />

how all buildings of its type and<br />

scale could and should now be constructed.<br />

The focus is on combining technical performance,<br />

environmental ethos and functionality,<br />

while taking into account the changing<br />

way people are living and working and perceiving<br />

the workplace.<br />

Well-being lies at the heart of the design.<br />

It’s about the materials used; what they<br />

are – predominantly<br />

bio-based<br />

– their aesthetic, how<br />

they’re perceived and<br />

how they make occupants<br />

feel. From the<br />

façade to the interiors,<br />

these are not just individual<br />

components<br />

of the building – they<br />

ARE the building. And<br />

structurally it’s an entirely wood solution.<br />

The key structural elements include a CLT<br />

core, floor and wall panels, plus the glulam<br />

frame for the façades.<br />

An eye-catching feature externally – and<br />

key contributor to the building’s energy performance<br />

– are the brise soleil fins in thermally-modified<br />

American Tulipwood. These<br />

are individually shaped using parametric<br />

modelling and are vertically or horizontally<br />

mounted according to the angle at which the<br />

sun strikes the building through the day. So<br />

they help maximize the building’s use of natural<br />

light, but break it up and control energy<br />

gain, minimizing the need for non-recyclable<br />

solar control coating on windows.<br />

AHEC worked with Waugh Thistleton in a technical<br />

advisory role on the specification of Tulipwood. It was<br />

chosen due to its technical performance and sustainability,<br />

with the species comprising 7 percent of the overall<br />

U.S. <strong>Hardwood</strong> forest. It has not been widely used thermo-treated,<br />

but where it has, such as in the Maggie’s<br />

Centre in Oldham and playground structures at Chisenhale<br />

school in London, it’s been shown to be durable,<br />

strong and stable in exterior use. AHEC-commissioned<br />

Please turn to page 72<br />

We have the experience, the capacity and state-of-the-art<br />

manufacturing equipment to handle all your White Oak needs.<br />

PARTNER WITH THE ORIGINAL GRAF BROTHERS!<br />

The Black and White Building<br />

Photography By Ed Reeve,<br />

Courtesy of AHEC<br />

BY MICHAEL SNOW,<br />

EXECUTIVE DIRECTOR,<br />

AMERICAN HARDWOOD EXPORT COUNCIL,<br />

STERLING, VA<br />

703-435-2900<br />

WWW.AHEC.ORG<br />

QUALITY / LOYALTY / TRADITION<br />

606-932-3117<br />

sales@grafbro.com<br />

24 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.grafbro.com

HARDWOOD FEDERATION INFO<br />

<br />

THE CORPORATE TRANSPARENCY ACT:<br />

A law you’ve never heard of, but need to pay attention to<br />

The <strong>Hardwood</strong> Federation would<br />

like to highlight a little-known reporting<br />

requirement that will be imposed<br />

on small and medium-sized<br />

businesses at the beginning of next<br />

year. The requirement results from<br />

enactment in 2021 of the Corporate<br />

Transparency ACT or CTA. The statute<br />

was signed into law to combat money laundering,<br />

tax fraud and other corruption as well as terrorist activity.<br />

In general, the law requires most existing and new corporate<br />

entities in the United States beginning January<br />

1, 2024, to file reports with the federal government regarding<br />

their beneficial owners. Reports are to be filed<br />

with the Department of the Treasury’s Financial Crimes<br />

Enforcement Network, or FinCEN.<br />

The impetus behind this new law was a sense from a<br />

majority in Congress at the time that criminals were increasingly<br />

exploiting corporate structures such as shell<br />

and front companies to hide their identities and move<br />

money through the U.S. financial system. As many U.S.<br />

states do not require corporations and similar entities to<br />

disclose information about their beneficial owners, Congress<br />

concluded that federal legislation providing for the<br />

collection of beneficial ownership information (BOI) for<br />

entities formed under the laws of U.S. states was necessary.<br />

Proponents of the CTA, and eventually Congress,<br />

viewed such legislation as necessary<br />

to protect vital U.S. national security<br />

interests, better enable law enforcement<br />

efforts to counter money laundering<br />

and the financing of terrorism<br />

and bring the U.S. into compliance<br />

with international anti-money laundering/combatting<br />

the financing of<br />

terrorism (AML/CFT) standards.<br />

So who must comply? Generally speaking, every<br />

existing, amended or new corporation, Limited Liability<br />

Company (LLC) or other entity created by filing registration<br />

papers with a secretary of state (or foreign entity<br />

registering to do business in the state), must file a report<br />

with FinCEN. The report must include the business<br />

name, current address, state of formation and Employer<br />

Identification Number of each entity, as well as the<br />

name, birth date, address and government issued photo<br />

ID (such as a driver’s license or passport) of every direct<br />

or indirect Beneficial Owner of the entity. The law<br />

defines “beneficial owner” as any individual who, directly<br />

or indirectly, either exercises substantial control over<br />

the reporting company or owns or controls at least 25<br />

percent of its ownership interests. While the required<br />

information is not terribly onerous, what has the business<br />

community’s increasing attention is the penalties<br />

for non-compliance. Failure by a “reporting company” to<br />

Please turn to page 72<br />

BY DANA LEE COLE,<br />

EXECUTIVE DIRECTOR,<br />

HARDWOOD FEDERATION,<br />

WASHINGTON, DC<br />

202-463-5186<br />

WWW.HARDWOODFEDERATION.WILDAPRICOT.ORG<br />

(800) 777-NYLE<br />

www.nyle.com<br />

kilnsales@nyle.com<br />

26 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 27

The Granite Valley Difference<br />

NAFF BULLETIN<br />

The The Granite Valley Difference<br />

The Granite Valley Difference<br />

YOUR SECRET WEAPON FOR COMMUNICATIONS<br />

Your strength and expertise is concentrated in the them up to date with tips and information they can use<br />

wood and forest products industry, but even so, you’re and share with their own customers. From factual resources<br />

to informational videos, tap into the tools avail-<br />

constantly communicating with one or more of your audiences.<br />

Customers, partners, current and potential employees,<br />

the community at large and the next generation Supply your customers with details on the sustainabiliable<br />

on our site.<br />

of wood-product users all are part of your circle of influence,<br />

and you have an ongoing need to stay in touch right building materials or product as one of the many<br />

ty of wood products as well as guidance on selecting the<br />

with all of them.<br />

ways you bring value to the relationship.<br />

Naturally, your message and relationship with each Keeping your social media lively and engaging while<br />

group is different, but you still need to provide value and sharing information that helps others get their jobs done<br />

keep people engaged with your message. When you takes work. We’ve compiled a wealth of wood facts and<br />

consider all the variation in communication needed and statistics that can add flavor to your communications.<br />

the multitude of avenues open to you, from social media Use what you need, and tag us when you do!<br />

to talking with kids to recruiting, keeping up with current<br />

Employees<br />

and<br />

Our<br />

useful<br />

sawmills<br />

supporting<br />

in<br />

information can seem daunting.<br />

Your employees are also ambassadors of the industry.<br />

Refresh your internal communications with news and<br />

Maybe Wisconsin you need prepare a secret weapon.<br />

If raw you’ve timber been for delivery reading this magazine a while, you’re<br />

Ready<br />

industry insights to keep your whole team aware of the<br />

already to our finishing aware of mills. the North American Forest Foundation,<br />

latest trends<br />

and our role in championing the forest products industry<br />

Custom and need-to-know information. Inventory<br />

Their view<br />

Quality<br />

of the industry and your company shapes the Our image average that on-hand<br />

and providing educational outreach. However, you might<br />

is communicated, Workpotentially attracting more kiln-dried people supply into is<br />

not be aware of the free resources Processing<br />

we have available to<br />

the industry. To help you streamline your 10 million board feet.<br />

help you deepen your relationships We “rough grade” with our all kiln-dried your audiences.<br />

woods to ensure the best appearance. can supply custom-cut<br />

with quick turnaround.<br />

Help your production workers process, develop we their personal Get and the professional<br />

skills within the wood products industry and sup-<br />

wood you need,<br />

Let’s look at the many Quality groups assurance you interact on every with load. and<br />

pre-production blanks<br />

port them to your with specs. training; let them see the range of opportunity<br />

that’s open to them.<br />

explore the resources you can use to provide value to<br />

these connections.<br />

Recruits and potential employees<br />

Customers Granite Valley Forest Products keeps growing as a single-source supplier to<br />

Like those in other industries, you’re probably feeling<br />

Ongoing better relationships serve you. We with sell customers rough, S2S, are straight-line vital. Keep ripping, the pinch and offer<br />

needing to recruit and hire skilled workers.<br />

NHLA grades and customer-proprietary grading based on NHLA guidelines.<br />

Custom products are available to your exact specs for width, length and color.<br />

Please turn to page 73<br />

Our Sawmills<br />

Visit our website to learn more or email us at sales@granitevalley.com.<br />

Offices in Wisconsin, Indiana<br />

& Colorado<br />

sales@granitevalley.com<br />

BY ALLISON DEFORD,<br />

granitevalley.com<br />

EXECUTIVE DIRECTOR,<br />

NORTH AMERICAN FOREST FOUNDATION,<br />

COLLIERVILLE, TN<br />

Alder | Aromatic Cedar | Black & White Ash | Aspen | Basswood<br />

901-860-4131<br />

Beech | White & Yellow Birch | Bitternut | Butternut | Cherry<br />

adeford@northamericanforestfoundation.org<br />

Grey & Red Elm | Hard Maple | Hickory | Red Oak | White Oak<br />

Norway Pine | White Pine | Poplar | Red & Silver Soft Maple | Walnut<br />

White Cedar | Rift & Quartered Red & White Oak<br />

Our Sawmills<br />

Our sawmills in<br />

Wisconsin prepare<br />

raw timber for delivery<br />

to our finishing mills.<br />

Granite Valley Forest Products keeps growing as a single-source supplier to<br />

better serve you. We sell rough, S2S, straight-line ripping, and offer<br />

NHLA grades and customer-proprietary grading based on NHLA guidelines.<br />

Our Sawmills<br />

Our Sawmills<br />

Our sawmills in<br />

Our Wisconsin<br />

Sawmills<br />

in prepare<br />

Our sawmills in<br />

Our raw Our timber sawmills for in in delivery<br />

Wisconsin prepare<br />

raw to Wisconsin our for<br />

finishing<br />

Offices prepare mills.<br />

in Wisconsin, Indiana<br />

raw timber for delivery<br />

to our<br />

raw raw timber timber for to our finishing mills. & for Colorado<br />

delivery<br />

to to our our finishing mills. mills. Quality<br />

sales@granitevalley.com Quality<br />

Processing<br />

Quality<br />

Custom products are available to your exact specs for width, length and color.<br />

Visit our website to learn more or email us at sales@granitevalley.com.<br />

To help you streamline your<br />

granitevalley.com We “rough Work<br />

Processing<br />

grade” our kiln-dried<br />

production process, we<br />

To help you woods to ensure the best appearance. To help To can To help help you supply you you streamline custom-cut streamline your<br />

your<br />

We We “rough we<br />

We Quality We “rough “rough grade” assurance grade” grade” our our kiln-dried<br />

our our on every kiln-dried load. production pre-production production process, process, blanks we we we<br />

Alder | Aromatic woods Cedar can woods woods to | to Black ensure to to &<br />

ensure ensure the White the best best<br />

the the Ash<br />

best appearance.<br />

best | Aspen appearance. | Basswood can can to supply can your supply specs.<br />

custom-cut<br />

Beech | White & Quality Yellow Quality Quality assurance Birch assurance | Bitternut on on every every<br />

on on | every Butternut every load. load.<br />

load. load. | Cherry<br />

pre-production blanks<br />

blanks<br />

Grey & Red Elm | Hard Maple | Hickory | Red Oak | White Oak to to your to your to your your specs.<br />

specs.<br />

Norway<br />

Granite<br />

Pine<br />

Valley<br />

| White<br />

Forest<br />

Pine<br />

Products<br />

| Poplar<br />

keeps<br />

| Red &<br />

growing<br />

Silver Soft<br />

as a<br />

Maple<br />

single-source<br />

| Walnut<br />

supplier to<br />

Granite White better<br />

Granite Granite Valley Valley<br />

Cedar serve<br />

Valley Forest Valley | Rift you.<br />

Forest Forest<br />

&<br />

Products We Quartered sell<br />

Products Products<br />

rough,<br />

keeps Red<br />

keeps keeps<br />

S2S, &<br />

growing White straight-line growing<br />

Oak<br />

as as a as a single-source as a a<br />

ripping, single-source<br />

and<br />

supplier offer<br />

supplier to<br />

to to to<br />

NHLA<br />

better better better serve better<br />

grades serve serve you. serve you. you. We We you.<br />

and<br />

sell We sell We<br />

customer-proprietary<br />

rough, sell sell rough, rough, S2S, S2S, S2S, straight-line S2S, straight-line<br />

grading based<br />

ripping, ripping, ripping,<br />

on NHLA<br />

and and and and offer<br />

offer offer offer<br />

guidelines.<br />

Custom<br />

NHLA NHLA NHLA grades<br />

NHLA grades grades grades<br />

products<br />

and and customer-proprietary and and<br />

are customer-proprietary<br />

available to your exact<br />

grading grading grading<br />

specs<br />

based based based<br />

for width,<br />

on on NHLA on on NHLA NHLA<br />

length<br />

guidelines.<br />

guidelines.<br />

and color.<br />

Visit<br />

Custom Custom Custom Custom<br />

our<br />

products products products<br />

website to<br />

are are available are are<br />

learn<br />

available available<br />

more or<br />

to to your your to to<br />

email<br />

your your<br />

exact exact exact exact<br />

us at<br />

specs specs specs specs<br />

sales@granitevalley.com.<br />

for for width, for width, for width, width,<br />

length length length<br />

and and and and<br />

color.<br />

color.<br />

color.<br />

Visit Visit our Visit our Visit<br />

website website our<br />

Offices our website website<br />

to to learn learn to<br />

in to learn learn<br />

more more Wisconsin,<br />

more more email email or or email email<br />

us us at us at Indiana us<br />

sales@granitevalley.com.<br />

at at sales@granitevalley.com.<br />

& Offices Colorado<br />

in in in Wisconsin, Indiana<br />

Offices in Wisconsin, Indiana<br />

& Colorado<br />

& sales@granitevalley.com<br />

& Colorado<br />

sales@granitevalley.com<br />

sales@granitevalley.com<br />

granitevalley.com<br />

granitevalley.com<br />

Quality<br />

Processing<br />

We “rough grade” our kiln-dried<br />

woods to ensure the best appearance.<br />

Quality assurance on every load.<br />

Alder | Aromatic Cedar | Black & White Ash | Aspen | Basswood<br />

granitevalley.com<br />

Beech | White & Yellow Birch | Bitternut | Butternut | Cherry<br />

Alder Grey Alder | Aromatic & | Aromatic Red Elm Cedar | Cedar Hard | Black Maple | Black & | Hickory & White<br />

White Ash | Ash Red | | Aspen Oak Aspen | | White | Basswood<br />

Basswood Oak<br />

Alder<br />

Alder<br />

| Aromatic<br />

| Aromatic Cedar | Black & White Ash Aspen | Basswood<br />

Beech Norway Beech | | White Pine White Cedar & | White & | Yellow Black<br />

Yellow Pine Birch & Birch | White Poplar | Bitternut Ash<br />

Beech | White & Yellow Birch | Bitternut | Bitternut | Red | Aspen | Butternut | Butternut & | Butternut Silver | Basswood Soft | Cherry<br />

| Cherry | Cherry Maple | Walnut<br />

Beech | Grey<br />

Grey White Grey & & Red<br />

& Red Cedar & Red Yellow Elm Elm<br />

Elm | Rift Birch | Hard | Hard<br />

| Hard & Quartered | Maple Bitternut | | Butternut | Cherry<br />

Maple<br />

Maple | Hickory<br />

| Hickory Red Hickory & | White | Red<br />

Red Oak<br />

Oak Oak Oak | White Oak<br />

| White<br />

| White Oak<br />

Oak<br />

Grey & Norway<br />

Norway<br />

Red Norway Elm Pine Pine<br />

Pine<br />

| Hard | White | White<br />

| White<br />

Maple Pine Pine<br />

Pine<br />

| | Poplar<br />

|<br />

Hickory | Poplar<br />

Poplar | |<br />

|<br />

Red | Red Silver<br />

&<br />

Oak & Silver<br />

Silver<br />

| White Soft Soft<br />

Soft Maple<br />

Maple<br />

Oak Maple | Walnut<br />

| Walnut<br />

| Walnut<br />

Norway White Pine | Cedar White | Pine Rift & | Poplar Quartered | Red Red & & Silver White Soft OakMaple | Walnut<br />

White White<br />

Cedar Cedar<br />

| Rift | Rift<br />

& &<br />

Quartered Quartered<br />

Red Red<br />

& &<br />

White White<br />

Oak<br />

Oak<br />

Custom<br />

Work<br />

To help you streamline your<br />

production process, we<br />

can supply custom-cut<br />

pre-production blanks<br />

to your specs.<br />

Custom<br />

Work Custom<br />

Work<br />

Work<br />

Our average on-hand<br />

kiln-dried supply is<br />

10 million board feet.<br />

Get the wood you need,<br />

with quick turnaround.<br />

Ready<br />

Inventory<br />

Ready<br />

Inventory<br />

Our average on-hand<br />

kiln-dried supply is<br />

Our 10 Our average million average board on-hand<br />

on-hand feet.<br />

kiln-dried Get is<br />

kiln-dried the supply wood supply you is<br />

isneed,<br />

10 10 10 with 10 million million quick board board turnaround. feet.<br />

feet.<br />

Get Get the Get the the wood wood you you need,<br />

with with quick quick turnaround.<br />

28 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

White Cedar | Rift & Quartered Red & White Oak<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 29<br />

Ready<br />

Inventory

NHLA: Why Knot...<br />

FIND YOUR OWN WAY TO SUPPORT RAHC<br />

AND BUILD YOUR WORLD<br />

I have 7 kids ages: 23, 21, 20,<br />

14, 12, 7, and 5 - three girls and<br />

four boys. They are so different.<br />

My oldest daughter is tall, skinny,<br />

blonde, average intelligence,<br />

above average work ethic, no<br />

musical ability, eats everything,<br />

and slow to get a joke. Her sister, who is two years<br />

younger is the exact opposite. She is short, stalky, brunette,<br />

above average intelligence, average work ethic,<br />

tons of musical ability, picky eater, and quick to get a<br />

joke. I could go on about each kid, but you get the picture.<br />

All parents know that one solution does not fit all kids.<br />

You can’t recreate the same outcome by doing the same<br />

thing with different kids. That is what makes parenting so<br />

hard and frustrating. You do the same thing and get seven<br />

different results. Most people don’t have seven kids;<br />

I am a glutton for punishment. However, having seven<br />

kids has prepared me to be a great association executive<br />

director because it has taught me to adapt to each kid<br />

according to their needs and desires. The same thing is<br />

true about businesses, associations and coalitions.<br />

A one-size-fits-all solution does not work for your employees,<br />

business, or <strong>Hardwood</strong> associations. The Real<br />

American <strong>Hardwood</strong> Coalition (RAHC) recognizes that<br />

and is working to allow for flexibility in fundraising. We<br />

are two months into the “Build Your World” campaign<br />

on Magnolia Network, HGTV, Hulu Live, and YouTube<br />

streaming services. The commercials<br />

are great and get the attention<br />

we need. If you have not<br />

seen them, check them out at<br />

the RealAmerican<strong>Hardwood</strong>.<br />

com website; they are top-notch.<br />

Additionally, RAHC’s social media<br />

accounts are growing in influence, producing great<br />

content, and getting more and more engagement. RAHC<br />

has accomplished a lot while keeping costs down and<br />

every association working in the same direction.<br />

We need a solution to organize and maintain long-term<br />

funding for the RAHC. The target of RAHC fundraising<br />

is $3,000,000/year. Current voluntary contributions from<br />

businesses have yet to be able to achieve more than<br />

$700,000/year. However, that was before we launched<br />

the consumer campaign. Hopefully, more (ALL) companies<br />

will contribute voluntarily to keep this going. However,<br />

not everyone can contribute dollars. However, I don’t<br />

think asking for $100 per million board feet from mills or<br />

$1,000 per million from suppliers to fund the RAHC is too<br />

much. But there are other ways to help Build Your World<br />

for those who choose not to donate money.<br />

First, make sure all your associations are contributing<br />

to the RAHC. We currently have 30 <strong>Hardwood</strong>-related associations<br />

contributing. There are more out there: state,<br />

forestry, equipment, logging, secondary manufacturing,<br />

and business associations connected to the <strong>Hardwood</strong><br />

industry, and we need everyone to contribute. Growing<br />

Please turn to page 75<br />

TRUSTED<br />

NATIONAL<br />

LEADER<br />

FULL BIOMASS WOOD<br />

BOILER SYSTEM<br />

Design, Fabrication and Installation – Hot Water and Steam<br />

• Lifetime Support of Equipment with Full-Service Team and Parts Division<br />

• Experts in All Aspects of Boiler Room Equipment – Combustion System, Boiler, Emissions<br />

Control Equipment, Controls, and Material Conveying Equipment<br />

• Installing throughout the US and Internationally<br />

BY DALLIN BROOKS,<br />

EXECUTIVE DIRECTOR,<br />

NATIONAL HARDWOOD LUMBER ASSOCIATION,<br />

MEMPHIS, TN<br />

901-377-1082<br />

WWW.NHLA.COM<br />

906-466-9010<br />

www.BurnChips.com sales@burnchips.com<br />

30 OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 31

“We believe building, renovating and restoring should be an exciting, fulfilling and<br />

pleasurable experience. We believe a partnership with E. F. San Juan can make dreams<br />

a reality. If you can imagine it, we can create it. Our craftsmen, designers and sales team,<br />

helmed by the company’s owners and dedicated leadership team, create innovative, artistic<br />

and efficient solutions. We do not just seek customers; we seek partners as committed to<br />

their experience as we are.”<br />

Buddy Czubaj, General Manager, E. F. San Juan<br />

E. F. San Juan released a short documentary film on the company’s growth, as well as introduced a web series titled<br />

Real Wood: Crafted Stories with Eddie San Juan.<br />

E. F. San Juan Is Building A Legacy<br />

Established in 1976, E. F. San<br />

Juan, located in Youngstown, FL, offers<br />

<strong>Hardwood</strong> architectural mouldings,<br />

millwork, cabinetry, windows<br />

and doors. Approximately 400,000<br />

board feet of domestic <strong>Hardwood</strong>s<br />

are purchased annually by E. F.<br />

San Juan. Species utilized in the<br />

manufacturing process include<br />

FAS1F Poplar, Red and White Oak,<br />

Hard and Soft Maple, Black Walnut,<br />

Cherry, Select and pecky Cypress.<br />

With inception dating back more<br />

than four decades, E. F. San Juan<br />

has overcome many challenges.<br />

Among them was a catastrophic<br />

category-five hurricane in <strong>October</strong><br />

of 2018 that decimated the company’s<br />

facilities, followed swiftly by the<br />

By Michelle Keller<br />

pandemic that created significant<br />

challenges just as they were finding<br />

their sea legs again after rebuilding.<br />

According to company president<br />

Edward A. San Juan, with hardship<br />

came opportunities for growth. “We<br />

adopted a new management method<br />

that transformed our company<br />

within that time frame after the hurricane.<br />

The gains we experienced<br />

from that are invaluable, even with<br />

the initial setbacks from the storm.<br />

We regrouped with our team and<br />

considered our options. We laid out<br />

a plan for a new building. It took<br />

about a year to reconstruct, and everything<br />

was laid out and connected<br />

with all the things we needed to<br />

run efficiently.”<br />

The life of a tree, with each unique grain and<br />

texture, brings its majestic beauty to every<br />

home bearing the E. F. San Juan fingerprint.<br />

With a highly skilled and dedicated workforce, E. F. San Juan continues<br />

to set the standard for quality architectura l millwork in the<br />

markets it serves in the Southeastern Coastal U.S. and beyond.<br />

E. F. San Juan is a third-generation family-owned company, from<br />

left to right, Edward San Juan, President, Ed San Juan, CEO, and<br />

Eddie San Juan, production manager. (Photo by Kyle Carpenter)<br />

E. F. San Juan was also in the process of fortifying<br />

a new cabinetry manufacturing facility during this time.<br />

“The cabinetry building was the only one that was not<br />

destroyed by the hurricane, so we moved our entire staff<br />

and operations into that building,” Edward shared. “My<br />

dad (Edward F. “Ed” San Juan) was key in implementing<br />

how we would get our divisions into new buildings. That<br />

cabinetry division was something that we had just started,<br />

and now it is clicking right along.” The division creates<br />