Dental Asia January/February 2024

For more than two decades, Dental Asia is the premium journal in linking dental innovators and manufacturers to its rightful audience. We devote ourselves in showcasing the latest dental technology and share evidence-based clinical philosophies to serve as an educational platform to dental professionals. Our combined portfolio of print and digital media also allows us to reach a wider market and secure our position as the leading dental media in the Asia Pacific region while facilitating global interactions among our readers.

For more than two decades, Dental Asia is the premium journal in linking dental innovators and manufacturers to its rightful audience. We devote ourselves in showcasing the latest dental technology and share evidence-based clinical philosophies to serve as an educational platform to dental professionals. Our combined portfolio of print and digital media also allows us to reach a wider market and secure our position as the leading dental media in the Asia Pacific region while facilitating global interactions among our readers.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

IN DEPTH WITH<br />

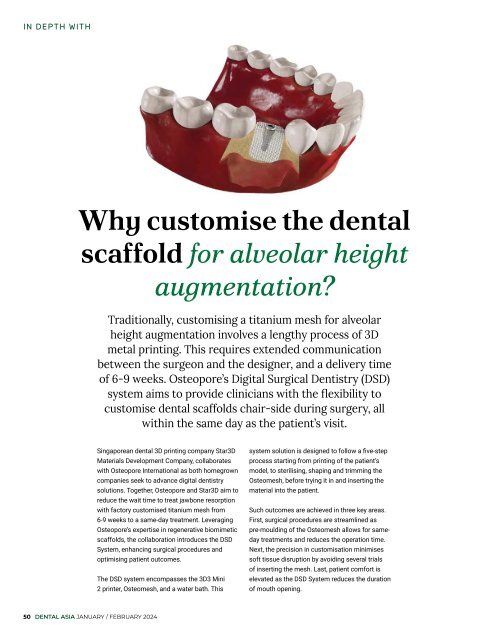

Why customise the dental<br />

scaffold for alveolar height<br />

augmentation?<br />

Traditionally, customising a titanium mesh for alveolar<br />

height augmentation involves a lengthy process of 3D<br />

metal printing. This requires extended communication<br />

between the surgeon and the designer, and a delivery time<br />

of 6-9 weeks. Osteopore’s Digital Surgical Dentistry (DSD)<br />

system aims to provide clinicians with the flexibility to<br />

customise dental scaffolds chair-side during surgery, all<br />

within the same day as the patient’s visit.<br />

Singaporean dental 3D printing company Star3D<br />

Materials Development Company, collaborates<br />

with Osteopore International as both homegrown<br />

companies seek to advance digital dentistry<br />

solutions. Together, Osteopore and Star3D aim to<br />

reduce the wait time to treat jawbone resorption<br />

with factory customised titanium mesh from<br />

6-9 weeks to a same-day treatment. Leveraging<br />

Osteopore’s expertise in regenerative biomimetic<br />

scaffolds, the collaboration introduces the DSD<br />

System, enhancing surgical procedures and<br />

optimising patient outcomes.<br />

The DSD system encompasses the 3D3 Mini<br />

2 printer, Osteomesh, and a water bath. This<br />

system solution is designed to follow a five-step<br />

process starting from printing of the patient’s<br />

model, to sterilising, shaping and trimming the<br />

Osteomesh, before trying it in and inserting the<br />

material into the patient.<br />

Such outcomes are achieved in three key areas.<br />

First, surgical procedures are streamlined as<br />

pre-moulding of the Osteomesh allows for sameday<br />

treatments and reduces the operation time.<br />

Next, the precision in customisation minimises<br />

soft tissue disruption by avoiding several trials<br />

of inserting the mesh. Last, patient comfort is<br />

elevated as the DSD System reduces the duration<br />

of mouth opening.<br />

50 DENTAL ASIA JANUARY / FEBRUARY <strong>2024</strong>