Dental Asia January/February 2024

For more than two decades, Dental Asia is the premium journal in linking dental innovators and manufacturers to its rightful audience. We devote ourselves in showcasing the latest dental technology and share evidence-based clinical philosophies to serve as an educational platform to dental professionals. Our combined portfolio of print and digital media also allows us to reach a wider market and secure our position as the leading dental media in the Asia Pacific region while facilitating global interactions among our readers.

For more than two decades, Dental Asia is the premium journal in linking dental innovators and manufacturers to its rightful audience. We devote ourselves in showcasing the latest dental technology and share evidence-based clinical philosophies to serve as an educational platform to dental professionals. Our combined portfolio of print and digital media also allows us to reach a wider market and secure our position as the leading dental media in the Asia Pacific region while facilitating global interactions among our readers.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

IN DEPTH WITH<br />

New capabilities and fully digital<br />

workflows with IBT Flex Resin<br />

Formlabs <strong>Dental</strong> materials portfolio sees a new addition with the IBT Flex<br />

Resin for 3D printed indirect bonding trays and direct composite restoration<br />

guides. Together with the Form 3B+ stereolithography (SLA) 3D printer, IBT<br />

Flex Resin can enable dentists, orthodontists, and dental lab technicians to<br />

improve clinical outcomes and deliver better results in less time.<br />

In what is said to be a first-of-its-kind capability for digital dentistry,<br />

dental professionals can use IBT Flex Resin to 3D print direct<br />

composite restoration guides to assist in the build-up of single units<br />

to full smile designs. Compared with traditional approaches, using a<br />

3D printed guide improves consistency and reduces procedure time<br />

and cost.<br />

IBT Flex Resin is biocompatible, FDA registered, and CE marked<br />

according to the EU MDR, and manufactured in the US at Formlabs’ ISO<br />

13485 certified facility for dental and medical materials development<br />

and manufacturing. IBT Flex Resin can be used in Formlabs Form 3B/+<br />

and Form 3BL resin 3D printers.<br />

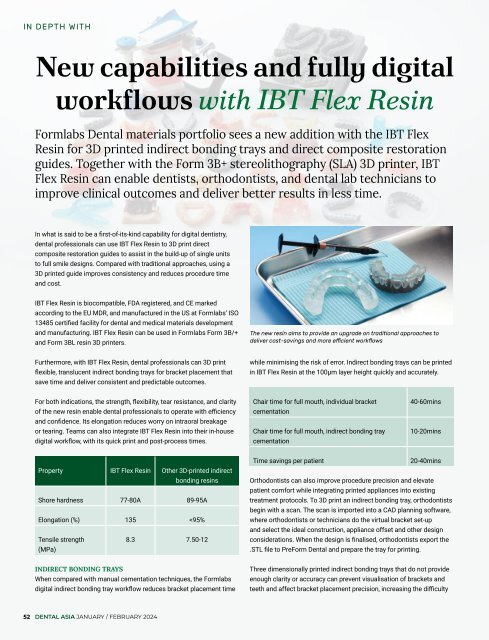

The new resin aims to provide an upgrade on traditional approaches to<br />

deliver cost-savings and more efficient workflows<br />

Furthermore, with IBT Flex Resin, dental professionals can 3D print<br />

flexible, translucent indirect bonding trays for bracket placement that<br />

save time and deliver consistent and predictable outcomes.<br />

while minimising the risk of error. Indirect bonding trays can be printed<br />

in IBT Flex Resin at the 100µm layer height quickly and accurately.<br />

For both indications, the strength, flexibility, tear resistance, and clarity<br />

of the new resin enable dental professionals to operate with efficiency<br />

and confidence. Its elongation reduces worry on intraoral breakage<br />

or tearing. Teams can also integrate IBT Flex Resin into their in-house<br />

digital workflow, with its quick print and post-process times.<br />

Chair time for full mouth, individual bracket<br />

cementation<br />

Chair time for full mouth, indirect bonding tray<br />

cementation<br />

40-60mins<br />

10-20mins<br />

Property IBT Flex Resin Other 3D-printed indirect<br />

bonding resins<br />

Shore hardness 77-80A 89-95A<br />

Elongation (%) 135