Future Auto March 2024

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

24 FUTURE AUTO | MINING<br />

“They can’t just switch diesel off straight away because<br />

they have to set up the electrical infrastructure of the<br />

mines themselves.”<br />

Big players<br />

The pressure to make positive change, Brendan said, is<br />

coming from the very top of the industry.<br />

“The big mining houses are predominantly the drivers of<br />

BEV/hybrid supply.<br />

“The majority of our sales are actually the<br />

subcontractors but the mining houses are the ones<br />

putting the big pressure on and a lot of that is driven<br />

by shareholders.<br />

“These companies want to be at the front for<br />

the change.”<br />

That pressure also trickles all the way to the bottom,<br />

more than a kilometre below the earth’s surface where<br />

some miners find themselves as old dogs learning<br />

new tricks.<br />

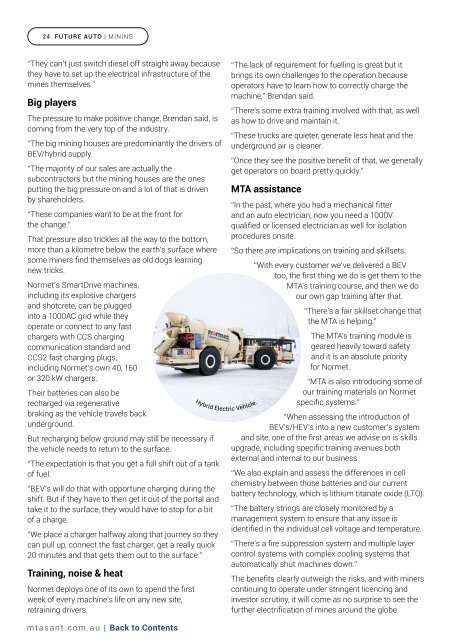

Normet’s SmartDrive machines,<br />

including its explosive chargers<br />

and shotcrete, can be plugged<br />

into a 1000AC grid while they<br />

operate or connect to any fast<br />

chargers with CCS charging<br />

communication standard and<br />

CCS2 fast charging plugs,<br />

including Normet’s own 40, 160<br />

or 320 kW chargers.<br />

Their batteries can also be<br />

recharged via regenerative<br />

braking as the vehicle travels back<br />

underground.<br />

But recharging below ground may still be necessary if<br />

the vehicle needs to return to the surface.<br />

“The expectation is that you get a full shift out of a tank<br />

of fuel.<br />

“BEV’s will do that with opportune charging during the<br />

shift. But if they have to then get it out of the portal and<br />

take it to the surface, they would have to stop for a bit<br />

of a charge.<br />

“We place a charger halfway along that journey so they<br />

can pull up, connect the fast charger, get a really quick<br />

20 minutes and that gets them out to the surface.”<br />

Training, noise & heat<br />

Normet deploys one of its own to spend the first<br />

week of every machine’s life on any new site,<br />

retraining drivers.<br />

mtasant.com.au | Back to Contents<br />

Hybrid Electric Vehicle.<br />

“The lack of requirement for fuelling is great but it<br />

brings its own challenges to the operation because<br />

operators have to learn how to correctly charge the<br />

machine,” Brendan said.<br />

“There’s some extra training involved with that, as well<br />

as how to drive and maintain it.<br />

“These trucks are quieter, generate less heat and the<br />

underground air is cleaner.<br />

“Once they see the positive benefit of that, we generally<br />

get operators on board pretty quickly.”<br />

MTA assistance<br />

“In the past, where you had a mechanical fitter<br />

and an auto electrician, now you need a 1000V<br />

qualified or licensed electrician as well for isolation<br />

procedures onsite.<br />

“So there are implications on training and skillsets.<br />

“With every customer we’ve delivered a BEV<br />

too, the first thing we do is get them to the<br />

MTA’s training course, and then we do<br />

our own gap training after that.<br />

“There’s a fair skillset change that<br />

the MTA is helping.”<br />

The MTA’s training module is<br />

geared heavily toward safety<br />

and it is an absolute priority<br />

for Normet.<br />

“MTA is also introducing some of<br />

our training materials on Normet<br />

specific systems.”<br />

“When assessing the introduction of<br />

BEV’s/HEV’s into a new customer’s system<br />

and site, one of the first areas we advise on is skills<br />

upgrade, including specific training avenues both<br />

external and internal to our business.<br />

“We also explain and assess the differences in cell<br />

chemistry between those batteries and our current<br />

battery technology, which is lithium titanate oxide (LTO).<br />

“The battery strings are closely monitored by a<br />

management system to ensure that any issue is<br />

identified in the individual cell voltage and temperature.<br />

“There’s a fire suppression system and multiple layer<br />

control systems with complex cooling systems that<br />

automatically shut machines down.”<br />

The benefits clearly outweigh the risks, and with miners<br />

continuing to operate under stringent licencing and<br />

investor scrutiny, it will come as no surprise to see the<br />

further electrification of mines around the globe.