reSolution_LNT_No1_en - Leica Microsystems

reSolution_LNT_No1_en - Leica Microsystems

reSolution_LNT_No1_en - Leica Microsystems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INDUSTRY<br />

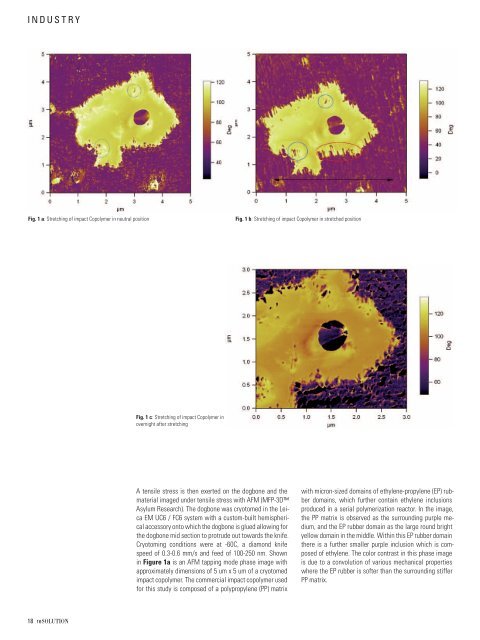

Fig. 1 a: Stretching of impact Copolymer in neutral position Fig. 1 b: Stretching of impact Copolymer in stretched position<br />

18 reSOLUTION<br />

Fig. 1 c: Stretching of impact Copolymer in<br />

overnight after stretching<br />

A t<strong>en</strong>sile stress is th<strong>en</strong> exerted on the dogbone and the<br />

material imaged under t<strong>en</strong>sile stress with AFM (MFP-3D<br />

Asylum Research). The dogbone was cryotomed in the <strong>Leica</strong><br />

EM UC6 / FC6 system with a custom-built hemispherical<br />

accessory onto which the dogbone is glued allowing for<br />

the dogbone mid section to protrude out towards the knife.<br />

Cryotoming conditions were at -60C, a diamond knife<br />

speed of 0.3-0.6 mm/s and feed of 100-250 nm. Shown<br />

in Figure 1a is an AFM tapping mode phase image with<br />

approximately dim<strong>en</strong>sions of 5 um x 5 um of a cryotomed<br />

impact copolymer. The commercial impact copolymer used<br />

for this study is composed of a polypropyl<strong>en</strong>e (PP) matrix<br />

with micron-sized domains of ethyl<strong>en</strong>e-propyl<strong>en</strong>e (EP) rubber<br />

domains, which further contain ethyl<strong>en</strong>e inclusions<br />

produced in a serial polymerization reactor. In the image,<br />

the PP matrix is observed as the surrounding purple medium,<br />

and the EP rubber domain as the large round bright<br />

yellow domain in the middle. Within this EP rubber domain<br />

there is a further smaller purple inclusion which is composed<br />

of ethyl<strong>en</strong>e. The color contrast in this phase image<br />

is due to a convolution of various mechanical properties<br />

where the EP rubber is softer than the surrounding stiffer<br />

PP matrix.