international - wwt-online.de

international - wwt-online.de

international - wwt-online.de

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

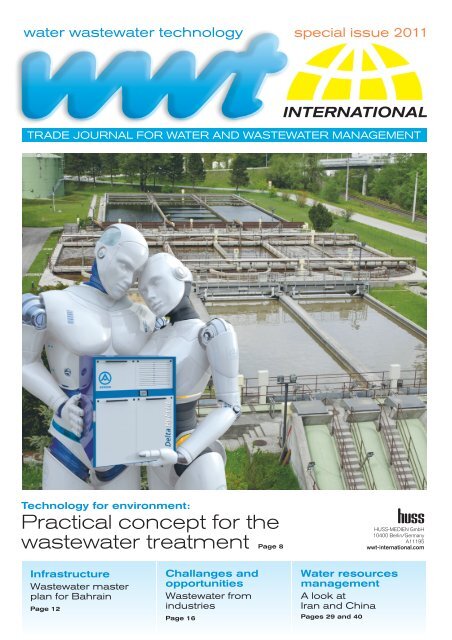

water wastewater technology special issue 2011<br />

Technology for environment:<br />

Practical concept for the<br />

wastewater treatment Page 8<br />

Infrastructure<br />

Wastewater master<br />

plan for Bahrain<br />

Page 12<br />

Challanges and<br />

opportunities<br />

Wastewater from<br />

industries<br />

Page 16<br />

INTERNATIONAL<br />

TRADE JOURNAL FOR WATER AND WASTEWATER MANAGEMENT<br />

Water resources<br />

management<br />

A look at<br />

Iran and China<br />

Pages 29 and 40<br />

huss<br />

HUSS-MEDIEN GmbH<br />

10400 Berlin/Germany<br />

A11195<br />

<strong>wwt</strong>-<strong>international</strong>.com

Crédits photos : Fotolia / iStockphoto / Egis Eau<br />

Innovative technologies and sustainable solutions for the water sector professionals<br />

<strong>international</strong><br />

water<br />

exhibition<br />

25 th >27 th May 2011<br />

MONTPELLIER, Exhibition Centre - FRANCE<br />

150 exhibitors International conference<br />

Business meetings Job forum<br />

Innovation trophies Training area<br />

www.hydrogaia-expo.com

Hans G. Huber<br />

Chairman of the Supervisory<br />

Board HUBER SE, Berching<br />

Appropriate technologies<br />

are nee<strong>de</strong>d<br />

In Germany, nothing is actually known about the global water shortage issue. We are<br />

fortunate in that we have sufficient quantities of water. We also have an excellent and<br />

efficient distribution system that provi<strong>de</strong>s drinking water to all areas. The same applies<br />

to wastewater disposal, which is subject to exemplary regulation in Germany.<br />

This positive situation often blinds us to the fact that water is an existential issue<br />

for many regions of the world.<br />

1.4 billion people in the world do not have access to clean DRINKING WATER;<br />

2.4 billion people do not have access to proper wastewater disposal facilities. This<br />

results in hunger and disease worldwi<strong>de</strong>. This problem not only affects arid regions, but<br />

is also becoming increasingly prevalent in some of the world’s largest cities.<br />

But this global problem cannot be solved by simply transferring German technology and<br />

expertise to these countries – the solution REQUIRES TECHNOLOGY that<br />

has been specially adapted in terms of the following:<br />

❙ Operability<br />

❙ Affordability<br />

❙ Implementation within the time available<br />

❙ Climatic conditions.<br />

The German water management industry is well placed to help solve these problems if it<br />

adapts to the needs of the target countries. Although much of the necessary technology<br />

has been <strong>de</strong>veloped, there is often a lack of PRACTICAL EXPERIENCE.<br />

This is often difficult to bring about, however, because the <strong>de</strong>cision-makers in the target<br />

countries simply want to copy the tried-and-tested solutions implemented in Germany<br />

and in other industrial countries.<br />

Another problem that must be addressed in many <strong>de</strong>veloping countries is that the<br />

administrative aspects necessary for organising and implementing regulated supplies<br />

of drinking water and wastewater disposal systems are lacking. This is an essential<br />

prerequisite for successful investments.<br />

All in all, the export opportunities for the German water management industry are<br />

strong, provi<strong>de</strong>d that the right technology is ma<strong>de</strong> available and that measures are taken<br />

to ensure that this TECHNOLOGY can be successfully operated.<br />

This means that the technology has to be transferred to the countries in question and<br />

that operating staff must be a<strong>de</strong>quately trained.<br />

The opportunities for the German water management industry are strong, and we can<br />

make an important contribution to solving some of the problems we see in the world.<br />

Your contact for <strong>wwt</strong> INTERNATIONAL:<br />

Main editorial office: Peter-Michael Fritsch Tel.: +49(0) 30 42151-221 huss<br />

Editorial staff: Petra Neumann Tel.: +49(0) 30 42151-291 HUSS-MEDIEN GmbH<br />

Advertising sales: Udo Magister Tel.: +49(0) 30 42151-403 Am Friedrichshain 22<br />

Sales: Wolfgang Krausch Tel.: +49(0) 30 42151-388 10407 Berlin/Germany<br />

Editorial<br />

<strong>wwt</strong>-<strong>international</strong>.com INTERNATIONAL<br />

1

CONTENT<br />

EDITORIAL<br />

1 Appropriate technologies are nee<strong>de</strong>d<br />

Hans G. HUBER<br />

WATER SCENE<br />

Feature<br />

4 WASSER BERLIN INTERNATIONAL 2011<br />

5 IFAT CHINA 2011<br />

6 A network on the road to success<br />

WASTEWATER<br />

Treatment<br />

8 Major wastewater treatment plant project –<br />

Ataköy, Istanbul<br />

Jens QUADT; Karsten SCHROEDER<br />

12 Wastewater master plan for Bahrain<br />

Bernhard HEINE<br />

Object report<br />

19 ORPU GmbH:<br />

Innovations in sewage water<br />

33 WILO SE:<br />

Optimisation of an wastewater treatment near Heilbronn<br />

37 Aerzener GmbH:<br />

Variable speed rotary blowers<br />

INDUSTRIAL WATER<br />

Mo<strong>de</strong>rn methods<br />

16 Water and wastewater treatment for Solar industry<br />

Elmar BILLENKAMP<br />

20 Mine Drainage Water Treatment in Vietnam<br />

Stefan KURTZ; Felix BILEK; Hans-Jürgen KOCHAN;<br />

Peter DENKE<br />

26 Treatment of wastewater from food processing industries<br />

Gesine GÖTZ; Andreas KUNZE; André REINICKE;<br />

Christopher GABLER, Sven-Uwe GEISSEN<br />

ENVIRONMENT<br />

Resource conversation<br />

29 Integrated water resources management in Iran<br />

Shahrooz MOHAJERI; Tamara NUNEZ VON VOIGT<br />

40 Management of the water resources in China<br />

Stefan KADEN; Bertram MONNINKHOFF<br />

2 INTERNATIONAL<br />

IMAGE OF TITLE: Variable speed rotary blowers for<br />

wastewater treatment systems<br />

Page 37<br />

Major wastwater treatment plant project<br />

– Atakköy, Istanbul<br />

Page 8<br />

2011

RUBRIC<br />

48 Publication <strong>de</strong>tails/Coupon<br />

SOLAR INDUSTRY: Industrial Water is becoming<br />

more and more important to preserve resources.<br />

Page 16<br />

Setting up a pilot plant for mine water treatment<br />

in Vietnam.<br />

Page 20<br />

Treatment of wastewater from food processing<br />

industries<br />

Page 26<br />

<strong>wwt</strong>-<strong>international</strong>.com INTERNATIONAL<br />

3

WATER SCENE Feature<br />

WASSER BERLIN INTERNATIONAL 2011:<br />

Attracts wi<strong>de</strong><br />

<strong>international</strong> attention<br />

WASSER BERLIN INTERNATIONAL is the meeting<br />

place for the water industry from all over the world.<br />

To date around 25 per cent of<br />

the exhibitors expected at<br />

the fair will be from abroad.<br />

This inclu<strong>de</strong>s three joint national<br />

displays hosted by China,<br />

a joint national display by Russia,<br />

and a pavilion representing<br />

the USA, where companies will<br />

be distributing information<br />

about their services and activities.<br />

Numerous exhibitors from<br />

the Middle East will also be<br />

represented in Berlin for the<br />

first time. International events<br />

will be further augmented by a<br />

Russia Day, organised by the<br />

Eastern Committee of German<br />

Industry and German Water<br />

Partnership. WASSER BERLIN<br />

Save the date:<br />

WASSER BERLIN<br />

INTERNATIONAL 2013<br />

from 15 to 18 April<br />

WASSER BERLIN<br />

INTERNATIONAL 2015<br />

from 20 to 23. April<br />

INTERNATIONAL attracted<br />

further attention following its<br />

recognition by the US Commercial<br />

Services as an “outstanding<br />

platform for presenting US<br />

products and services.”<br />

NO DIG 2011<br />

In 2011, WASSER BERLIN<br />

INTERNATIONAL will incorporate<br />

the INTERNATIONAL<br />

NO DIG for the first time, where<br />

the latest <strong>de</strong>velopments and<br />

technology in trenchless pipe<br />

laying will be on display. In<br />

2008, using trenchless technology<br />

750 kilometres of pipes<br />

were built in Berlin alone, saving<br />

around 64 million euros in<br />

costs.<br />

International standing<br />

As regards topics, a forum atten<strong>de</strong>d<br />

by several nations will<br />

WASSER BERLIN INTERNATIONAL 2011:<br />

from 2 to 5 Mai Image 1<br />

WWT-INTERNATIONAL: Hall 2.2, Stand 202b<br />

Stand: 27.01.2011<br />

NO DIG: is a further highlight at the WASSER Image 2<br />

BERLIN INTERNATIONAL 2011 Fotos: Messe Berlin<br />

un<strong>de</strong>rline the event’s <strong>international</strong><br />

standing. Every day of the<br />

fair the latest water industry issues<br />

concerning the respective<br />

countries will be discussed<br />

here. Among the nations attending<br />

will be Russia, Romania,<br />

Bulgaria, Jordan, numerous<br />

Central Asian states, and Turkey.<br />

To facilitate face-to-face<br />

meetings and in or<strong>de</strong>r to promote<br />

business relations an extensive<br />

supporting programme<br />

will be taking place.<br />

“The <strong>international</strong> attention the<br />

fair has attracted is due to two<br />

main factors”, said Cornelia<br />

Wolff von <strong>de</strong>r Sahl, Project<br />

Manager at Messe Berlin. “On<br />

the one hand the water industry<br />

is becoming more globalized.<br />

Against this backdrop, with its<br />

extensive programme of congress<br />

events is becoming an increasingly<br />

important industry<br />

platform. On the other hand, our<br />

direct involvement in other<br />

countries, our <strong>international</strong><br />

contacts and the work carried<br />

out by our foreign representatives<br />

has had a positive impact.”<br />

As of 2011 the format of the fair<br />

will be optimized to run over<br />

four days at intervals of every<br />

two years.<br />

Congress programm<br />

It is also the first time that the<br />

accompanying congress programme<br />

wat + WASSER BER-<br />

LIN INTERNATIONAL will<br />

be jointly organized by all the<br />

relevant specialist organizations,<br />

un<strong>de</strong>r the aegis of the<br />

DVGW. More than 120 highprofile<br />

experts representing research,<br />

politics and industry<br />

will <strong>de</strong>liver their reports on all<br />

the issues concerning the water<br />

industry at 18 tracks un<strong>de</strong>r a<br />

variety of headings.<br />

CONTACT<br />

www.wasser-berlin.com<br />

Non-commercial sponsors:<br />

DVGW German Technical<br />

Association for Gas and Water<br />

www.dvgw.<strong>de</strong><br />

FIGAWA Association of Companies in<br />

the Gas and Water Industries<br />

www.figawa.<strong>de</strong><br />

IWA International Water<br />

Association<br />

www.iwahq.org.uk<br />

4 INTERNATIONAL<br />

2011

IFAT CHINA + EPTEE + CWS 2011:<br />

Information<br />

platform<br />

Supporting program inclu<strong>de</strong>s<br />

technical and scientific conferences,<br />

workshops, theme specials and<br />

exhibitor presentations.<br />

The highlight of this year‘s<br />

supporting program at<br />

IFAT CHINA + EPTEE +<br />

CWS, which takes place at the<br />

Shanghai New International<br />

Expo Centre from 5 to 7 May, is<br />

a workshop on “Earth System<br />

Engineering: Challenges and<br />

Chances on the way to a sustainable<br />

world”, which is being organized<br />

by CRAES – the Chinese<br />

Research Aca<strong>de</strong>my of the<br />

Environmental Sciences (Beijing)<br />

– and IESP – International<br />

Group for Earth Systems Preservation<br />

(Munich) – in close<br />

conjunction with the Bavarian<br />

State Ministry of the Environment<br />

and Public Health<br />

(StMUG) and Messe München<br />

International (MMI).<br />

Experts from China and Europe<br />

will hold lectures and discuss<br />

environmental issues around the<br />

world including climate change,<br />

dwindling energy supplies, the<br />

food shortage and social imbalance,<br />

especially when it comes<br />

to water. They will join participants<br />

in <strong>de</strong>bating holistic solutions<br />

and gui<strong>de</strong>lines for responsible<br />

action on the part of the<br />

commercial and political sectors.<br />

The IESP workshop was well<br />

received by the audience last<br />

year. So to meet the requirement<br />

of the audience, this year the<br />

IESP workshop is prolonged to<br />

one and a half days on May 5<br />

and May 6.<br />

Scientific<br />

conferences<br />

As in the past, the German Association<br />

for Water, Wastewater<br />

and Waste (DWA) is organizing<br />

a series of technical and scientific<br />

conferences at IFAT<br />

CHINA + EPTEE + CWS.<br />

Among other things, key topics<br />

inclu<strong>de</strong> water supply, waste<br />

water, sewage sludge treatment,<br />

waste disposal, sewer systems<br />

and environmental technologies.<br />

Several events are being<br />

organized in cooperation with<br />

the Toingji University Shanghai,<br />

as for example the meeting<br />

of the “Young Water Professionals”<br />

on May 5. The event covers<br />

the theme “China Environmental<br />

Protection Industry – Market,<br />

Strategy, Perspective”.<br />

For the third time, Germany‘s<br />

Fe<strong>de</strong>ral Ministry for the Environment,<br />

Nature Conservation<br />

and Nuclear Safety (BMU) is<br />

organizing a workshop on “Sustainable<br />

Solid Waste Management<br />

and Resource Efficiency”<br />

on May 5 and a workshop on<br />

“Circular Economy – Contribution<br />

to Resource Management<br />

and Climate Protection” on May<br />

6. The workshop will focus on<br />

treatment and energy recovery<br />

of waste and biotechnical solutions<br />

to solve waste problems<br />

and addresses experts in the<br />

water and energy sectors.<br />

Another highlight is fact that the<br />

Parliamentary State Secretary<br />

Katherina Reiche of the Fe<strong>de</strong>ral<br />

Ministry for the Environment,<br />

Nature Conservation and Nuclear<br />

Safety in Germany will<br />

not only officially open IFAT<br />

CHINA + EPTEE + CWS but<br />

will also use this event to enter<br />

into a dialog with the industry.<br />

Pump Forum<br />

In addition to that, IFAT<br />

CHINA + EPTEE + CWS also<br />

features a premiere: The “2011<br />

Pump Forum” will be held for<br />

the first time on May 5. With the<br />

theme of “Bring Benefits to Different<br />

Pump Users”, the forum<br />

aims to propagate the i<strong>de</strong>a of<br />

saving energy and reliable tech-<br />

nology, propel the application of<br />

high-efficiency, low-consumption<br />

and energy-saving products,<br />

and create a face-toface<br />

communication platform for<br />

users and manufactures.<br />

Simultaneous translation into<br />

Chinese and English will be<br />

provi<strong>de</strong>d for all events in the<br />

supporting program. Participation<br />

in the supporting program<br />

is free of charge for those who<br />

participate in IFAT CHINA +<br />

EPTEE + CWS 2011.<br />

Feature<br />

IFAT CHINA is Asia´s most comprehensive tra<strong>de</strong> show<br />

for the water sector and sewage treatment, for waste<br />

disposal and recycling Image 2<br />

About IFAT<br />

CHINA 2010:<br />

❙ 839 exhibitors<br />

from 26 countries<br />

❙ over 22,000 visitors<br />

from 84 countries<br />

CONTACT<br />

www.ifat-china.com<br />

<strong>wwt</strong>-<strong>international</strong>.com INTERNATIONAL<br />

5

WATER SCENE Feature<br />

German Water Partnership (GWP):<br />

A network on the<br />

road to success<br />

GWP sees itself as a network<br />

<strong>de</strong>signed to establish the German<br />

water management industry on the<br />

<strong>international</strong> markets.<br />

Reference works of all type<br />

– digital or analogue – <strong>de</strong>fine<br />

strategy (Ancient Greek:<br />

strategós, the general, the comman<strong>de</strong>r)<br />

as “a long-term tactical<br />

striving towards a goal, taking<br />

the available means and resources<br />

into consi<strong>de</strong>ration.”<br />

Almost the very same <strong>de</strong>finition<br />

can be found in the relevant<br />

publications, a <strong>de</strong>finition as<br />

un<strong>de</strong>rstood in the conventional<br />

sense by the business world: “a<br />

behavioural pattern employed<br />

by companies and mainly<br />

planned in the long term in or<strong>de</strong>r<br />

to achieve their goals.”<br />

Strategy <strong>de</strong>termines the success;<br />

putting it in a nutshell, one<br />

could also say that strategy is<br />

the art of doing the right things,<br />

with the right people, in the<br />

right place and at the right time.<br />

The Canadian Professor of<br />

Management Studies, Henry<br />

Mintzberg, <strong>de</strong>fines strategy in<br />

terms of five Ps, namely “Strategy<br />

is:<br />

❙ a Plan (a planned strategy)<br />

❙ a Pattern (the strategy implemented)<br />

❙ a Position (the position on the<br />

market)<br />

❙ a Perspective (how goals are<br />

achieved)<br />

❙ a Ploy (a manoeuvre for surviving<br />

in a competitive environment)”.<br />

In principle, German Water<br />

Partnership (GWP) also acts in<br />

accordance with these five Ps,<br />

which create transparency, systematics,<br />

structure and strategic<br />

orientation for everyone. This is<br />

necessary and offers additional<br />

clarity as GWP monitors different<br />

goals simultaneously, goals<br />

which each require different<br />

strategies.<br />

In addition, strategies are supported<br />

by means of tactical elements<br />

which can be implemented<br />

at short notice in<br />

operating business.<br />

A plan – the planned<br />

strategy<br />

In cooperation with its members<br />

from companies, professional<br />

associations and research establishments<br />

from the German<br />

water sector, GWP has <strong>de</strong>dicated<br />

itself to four core issues:<br />

Position of the “German Water Partnership” brand<br />

❙ a safe water supply<br />

❙ efficient water treatment<br />

❙ sustainable water usage<br />

❙ capacity <strong>de</strong>velopment<br />

These goals are to be fulfilled<br />

for as many people as possible,<br />

German Water Partnership at IFAT ENTSORGA 2010 in Munich Image 1<br />

particularly in <strong>de</strong>veloping and<br />

threshold countries.<br />

The long-term goal is therefore<br />

to give these people access to<br />

clean water, to ensure careful<br />

wastewater treatment and sanitation<br />

facilities as well as the<br />

recirculation of the resource, to<br />

protect water as a resource for<br />

coming generations, and finally<br />

to establish a global capacity<br />

<strong>de</strong>velopment concept so that the<br />

UN millennium goals can be<br />

reached.<br />

This requires shared strengths<br />

with experience, expertise and<br />

know-how. And this is exactly<br />

what German Water Partnership<br />

has brought together un<strong>de</strong>r one<br />

roof. Here you can find the experience,<br />

expertise and knowhow<br />

of the German water management<br />

industry and research<br />

community, among the most<br />

powerful in the world. Here is<br />

where everything comes together<br />

and here is where multifaceted<br />

support at political level<br />

comes into play via the five<br />

Fe<strong>de</strong>ral Ministries: BMU (Environment),<br />

BMBF (Research),<br />

BMZ (Cooperation), BMWi<br />

(Economy) and the Fe<strong>de</strong>ral<br />

Foreign Office, which acts as an<br />

additional reinforcing component.<br />

With such a powerful<br />

network, partners outsi<strong>de</strong> Germany<br />

have a central contact<br />

person at their disposal for any<br />

water-related queries they may<br />

have.<br />

The GWP partners and members<br />

– all of whom have been<br />

incorporated into this network<br />

– act as guarantors for longlasting,<br />

high-quality, fail-safe<br />

and up-to-date products and<br />

solutions as well as for a reliable,<br />

qualified and effective<br />

service.<br />

Close cooperation between all<br />

partners ensures that German<br />

expertise, experience and knowhow<br />

are harnessed throughout<br />

the world in such a way that<br />

the goals which have been set<br />

can be reached. The planned<br />

strategy, Plan (1), has thus been<br />

clearly <strong>de</strong>fined.<br />

A pattern – the strategy<br />

implemented<br />

In the search for a pattern which<br />

had led to success, i.e. for a<br />

strategy which has already been<br />

implemented, GWP can point to<br />

6 INTERNATIONAL<br />

2011

The focus countries and regions of German Water Partnership Image 2<br />

numerous elements taken from<br />

its own ranks such as:<br />

❙ ongoing projects<br />

❙ individual success stories and/<br />

or partial successes in projects<br />

❙ success stories and/or partial<br />

successes from a variety of<br />

activities and actions.<br />

To make this manpower, technology<br />

and specialist “Ma<strong>de</strong> in<br />

Germany” knowledge known<br />

outsi<strong>de</strong> Germany, GWP has<br />

participated in – and continues<br />

to participate in – numerous<br />

tra<strong>de</strong> fairs, congresses, conferences,<br />

workshops, symposia,<br />

visits from <strong>de</strong>legations, seminars<br />

etc. at an <strong>international</strong> level<br />

– and has already ma<strong>de</strong> a name<br />

for itself. The company always<br />

participates in such events with<br />

a specific eye on those countries<br />

in which German know-how is<br />

in <strong>de</strong>mand and investments in<br />

the water management infrastructure<br />

have been planned and<br />

are necessary. The various<br />

presentations in the relevant<br />

countries ensure the successful<br />

creation and expansion of intensive,<br />

long-term and confi<strong>de</strong>ncebuilding<br />

contacts with networks,<br />

individuals, authorities and institutions,<br />

which can then be<br />

expan<strong>de</strong>d to generate further<br />

success. In addition, working<br />

groups which initiate and maintain<br />

contacts in their own coun-<br />

try, enter cooperation agreements<br />

on site and start projects<br />

were established in the GWP<br />

focus countries <strong>de</strong>fined in 2009.<br />

These refer not only to the <strong>de</strong>veloping<br />

and threshold countries<br />

<strong>de</strong>scribed above, but also<br />

target countries such as Turkey,<br />

Bulgaria, Romania and Croatia.<br />

Current examples of success,<br />

both in the field of research as<br />

well as water supply and wastewater<br />

disposal, which are based<br />

on implemented strategies, can<br />

be found in Vietnam, Jordan,<br />

Isfahan in Iran, Russia and even<br />

the Gulf States.<br />

A position – the position<br />

on the market<br />

After almost three years,<br />

GWP’s position on the German<br />

market with over 300 members<br />

from companies, professional<br />

associations and research institutions<br />

from the German water<br />

sector is almost without dispute.<br />

The GWP network promotes<br />

contacts, an exchange of i<strong>de</strong>as<br />

and information between the<br />

partners from the world of business,<br />

research and politics, and<br />

is actively used as a platform for<br />

penetrating new <strong>international</strong><br />

markets in a variety of ways and<br />

recognising trends in the water<br />

management industry at an<br />

early stage.<br />

Within this network, the German<br />

water management industry<br />

is positioned on the <strong>international</strong><br />

markets along the entire<br />

ad<strong>de</strong>d value chain; a global<br />

market share of 24% can already<br />

be recor<strong>de</strong>d for “Ma<strong>de</strong> in<br />

Germany”.<br />

A perspective –<br />

how the goals are<br />

achieved<br />

The goals for the German Water<br />

Partnership network are distributed<br />

across the world. In or<strong>de</strong>r<br />

to achieve them, the relevant<br />

tasks must be taken into account.<br />

Put simply, GWP also<br />

regards its role as including:<br />

❙ strengthening the competitive<br />

position of the German water<br />

management companies on<br />

the <strong>international</strong> markets<br />

❙ intensifying the transfer of<br />

Germany technology, bundling<br />

information for this<br />

purpose<br />

❙ improving the basic conditions<br />

for business <strong>de</strong>velopment<br />

and<br />

❙ encouraging innovations.<br />

GWP also receives valuable<br />

support and help in this context<br />

from the BMU, BMBF, BMZ,<br />

BMWi and the Fe<strong>de</strong>ral Foreign<br />

Office as well as through cooperation<br />

with the GIZ Gesellschaft<br />

für Internationale Zusam-<br />

Feature<br />

menarbeit and gtai Germany<br />

Tra<strong>de</strong> and Invest.<br />

Seen on their own, covering the<br />

current immense <strong>de</strong>mand for<br />

investments in the global water<br />

sector and supplying the world’s<br />

population with clean drinking<br />

water are major goals with major<br />

prospects for all those involved.<br />

A Ploy, a manoeuvre based on<br />

illusion, in or<strong>de</strong>r to survive in a<br />

competitive environment does<br />

not appear appropriate for<br />

GWP; the structures, tasks and<br />

goals are not very suitable for<br />

this.<br />

Outlook<br />

GWP started life three years<br />

ago with the strategic opportunities<br />

of a thriving, sustainable<br />

network and the expertise and<br />

know-how of the participants<br />

involved, and it is sticking firm<br />

to these. This has allowed GWP<br />

to achieve a series of both major<br />

and minor successes, to initiate<br />

projects, conclu<strong>de</strong> cooperation<br />

agreements and enter into partnerships.<br />

Many clients and <strong>de</strong>cisionmakers<br />

from all over the world<br />

now see the GWP brand as a<br />

fast track to German expertise<br />

and experience in the water<br />

management industry. Step by<br />

step and in cooperation with its<br />

members and partners, GWP is<br />

thus achieving the goals it has<br />

set itself of “giving as many<br />

people as possible access to<br />

clean water, ensuring careful<br />

wastewater treatment and sanitation<br />

facilities as well as the<br />

recirculation of the resource,<br />

protecting water as a resource<br />

for coming generations, and finally<br />

establishing a global capacity<br />

<strong>de</strong>velopment concept.<br />

So the strategy is working!<br />

CONTACT<br />

Dipl.-Ing. Stefan GIROD<br />

Director General<br />

German Water Partnership e.V.<br />

Reinhardtstraße 32<br />

10117 Berlin<br />

GERMANY<br />

Tel. +49/30 300199-1220<br />

Fax. +49/30 300199-3220<br />

E-mail: stefan.girod@<br />

germanwaterpartnership.<strong>de</strong><br />

Web:<br />

www.germanwaterpartnership.<strong>de</strong><br />

<strong>wwt</strong>-<strong>international</strong>.com INTERNATIONAL<br />

7

WASTEWATER Sewage systems<br />

Jens QUADT; Karsten SCHROEDER<br />

Major wastewater<br />

treatment plant project –<br />

Ataköy, Istanbul<br />

Essen-based company WTE provi<strong>de</strong>d the planning<br />

and operating concept for the wastewater treatment plant<br />

in Ataköy, Istanbul.<br />

With around 12.8 million inhabitants,<br />

Istanbul, UNESCO world heritage<br />

site and the only capital in the world situated<br />

on two continents, is one of the largest cities<br />

in the world. Its rapid growth and high industrial<br />

and traffic <strong>de</strong>nsity present a great<br />

challenge for the protection of health and<br />

the environment.<br />

Alignment to EU law<br />

For the institutions involved, the alignment<br />

of Turkish regulations to EU standards has<br />

created a need for action. The Turkish Ministry<br />

of the Environment has therefore<br />

drawn up an ambitious programme for upgrading<br />

wastewater purification facilities.<br />

One goal of this plan is to purify the wastewater<br />

of the most heavily-populated city in<br />

Turkey effectively and to adhere reliably to<br />

the discharge values <strong>de</strong>man<strong>de</strong>d.<br />

The largest project currently inclu<strong>de</strong>d in this<br />

programme, the new wastewater treatment<br />

plant in the Istanbul district of Ataköy near<br />

Atatürk airport, was completed in November<br />

2009. In May 2007, consortium lea<strong>de</strong>r<br />

WTE Wassertechnik GmbH (Essen), together<br />

with the two Turkish construction<br />

companies Lidya and Kalyon, received an<br />

or<strong>de</strong>r from the Istanbul Metropolitan Water<br />

and Sewerage Company (ISKI) to construct<br />

a new wastewater purification plant for<br />

around 2 million inhabitants (population<br />

equivalents). The value of the or<strong>de</strong>r was<br />

EUR 108 million and inclu<strong>de</strong>d a 3-stage<br />

biological wastewater purification plant<br />

with further nitrogen removal and subsequent<br />

sludge digestion. It had been prece<strong>de</strong>d<br />

by an ambitious competition between wellknown<br />

European rival companies.<br />

Final plant acceptance by ISKI was carried<br />

out on schedule. Subsequent plant operation,<br />

which is being handled by the German<br />

company for 5 years, began at the start of<br />

2010 (Images 1 and 2). Municipal and industrial-commercial<br />

wastewater from the Istanbul<br />

districts of Bakirköy, Bahcelievler,<br />

Bagcilar and partly from Kücükcekmece<br />

and Sultangazi is treated at the plant, making<br />

the high polluting load levels caused by<br />

largely untreated discharges into the rivers<br />

Ayamama and Tavukcu a thing of the past.<br />

The high polluting load levels caused by<br />

largely untreated discharges into the rivers<br />

Ayamama and Tavukcu are thus a thing of<br />

the past. The size of the Ataköy wastewater<br />

treatment plant project is unparalleled in the<br />

European sphere and placed the highest<br />

<strong>de</strong>mands on the planning and project management<br />

teams. Such were the major challenges<br />

taken on by the project teams in the<br />

consortium. In this connection, the primary<br />

task of WTE was complete installation planning<br />

and the process engineering-related<br />

<strong>de</strong>sign of the plant as well as the supply and<br />

installation of the machinery and electrical<br />

engineering equipment.<br />

The expertise and extensive operational<br />

experience already gathered by WTE as an<br />

operator of large wastewater treatment<br />

plants (e.g. Zagreb and Moscow) had some<br />

influence on the planning and operating<br />

concept of the Ataköy plant. Ultimately,<br />

however, it was the operating costs that<br />

proved to be the final <strong>de</strong>cisive factor in<br />

awarding the contract to the consortium.<br />

Technical <strong>de</strong>sign data<br />

The Ataköy wastewater treatment plant was<br />

planned as an activated sludge plant in a<br />

casca<strong>de</strong> arrangement. When the plant was<br />

<strong>de</strong>signed, special importance was attached<br />

to minimising energy consumption.<br />

The wastewater engineering calculations for<br />

the biological stage, including calculating<br />

the oxygen required, were un<strong>de</strong>rtaken in<br />

accordance with the standard rules and<br />

regulations of ATV process flow sheet A<br />

131 (2000):<br />

❙ Capacity: approximately 2 million EW<br />

❙ Wastewater volume: 510,000 m3/d, after<br />

final completion 780,000 m3/d after final<br />

completion<br />

❙ Maximum wastewater concentrations in<br />

discharge:<br />

• BSB 5 : 25 mg/l<br />

• CSB: 125 mg/l<br />

• TSe: 35 mg/l<br />

• Total N: 10 mg/l<br />

• Total P: 3 mg/l<br />

Installation engineering<br />

Intake pumping station with<br />

upstream screen<br />

The very scale of the intake pumping station<br />

constituted a new challenge for the planners.<br />

The pumping station, ma<strong>de</strong> to a concrete<br />

circular <strong>de</strong>sign, was planned and produced<br />

with a diameter of approximately 22 m and<br />

an overall <strong>de</strong>pth of approximately 16 m.<br />

On both si<strong>de</strong>s of the Ayamama, three pipes<br />

(DN 2600, DN 1600 and DN 1400) were<br />

merged in a collection structure. Through a<br />

connecting pipe from the collection structure<br />

to the combining shaft of the intake<br />

pumping station, the water is conveyed via<br />

a DN 2400 pipe to the intake pumping station.<br />

A mechanical coarse screen was placed<br />

upstream of the intake pumping station for<br />

protection against coarse wastewater materials.<br />

Through the intake pumping station, the<br />

wastewater flowing to the wastewater treatment<br />

plant at a maximum volume of 32,500<br />

m3/h is conveyed into the intake channel of<br />

the wastewater treatment plant. Nine submersible<br />

motor pumps convey the inflow<br />

water to a level of approximately 8 m, from<br />

where the entire wastewater treatment plant<br />

is floo<strong>de</strong>d un<strong>de</strong>r gravity down to the discharge<br />

structure.<br />

Mechanical wastewater<br />

pretreatment<br />

The wastewater is dispersed into a total of<br />

nine screen channels in the screen building.<br />

The three aerated twin-chamber grit traps<br />

were <strong>de</strong>signed for a filter throughput rate of<br />

8 INTERNATIONAL<br />

2011

Sewage systems<br />

LARGEST CURRENT WASTEWATER PROJECT: Ataköy, Istanbul wastewater treatment plant Image 1<br />

780,000 m3/day (total capacity). Up to 50%<br />

of the wastewater flows out of the grit trap<br />

to the primary clarifiers. The remaining<br />

wastewater stream flows directly to the<br />

sprea<strong>de</strong>r unit of the activated sludge tanks.<br />

Biological stage<br />

The sprea<strong>de</strong>r unit, with a biological phosphorus<br />

area, disperses the stream into the<br />

three activated sludge tank lines. At the biological<br />

purification stage, the carbon compounds<br />

are broken down and the nitrogen<br />

and phosphorous nutrients removed. The<br />

capacity of the activated sludge lines is<br />

i<strong>de</strong>ntical – 99,258 m3 each; the dimensions<br />

are 179 m x 83 m.<br />

In each tank, the sludge-water mixture is<br />

kept in suspension by means of slowly running<br />

submersible motor-driven agitators.<br />

Aeration is provi<strong>de</strong>d by the introduction of<br />

compressed air with fine bubbles released<br />

via disc aerators.<br />

Air supply is guaranteed by means of 12<br />

turbo blowers (each 20,000 Nm3/h) with a<br />

combined capacity of 240,000 Nm3/h in the<br />

blower station.<br />

The biologically purified wastewater from<br />

the activated sludge tanks reaches the sec-<br />

ondary settlement tanks via the sprea<strong>de</strong>r<br />

units. The water flows into 12 circular tanks,<br />

each with a diameter of 44 m, a surface of<br />

1,526 m 2 and a volume of 21,250 m3.<br />

In the secondary settlement tanks, the<br />

flushed activated sludge is separated from<br />

the purified wastewater by sedimentation<br />

un<strong>de</strong>r the influence of gravity. The tanks are<br />

equipped with scraper bridges. Sludge<br />

scrapers convey the activated sludge separated<br />

off at the bottom of the secondary<br />

sedimentation tank to the central secondary<br />

Construction of the activated sludge stage Image 2<br />

<strong>wwt</strong>-<strong>international</strong>.com INTERNATIONAL<br />

9

WASTEWATER Sewage systems<br />

Construction of the phosphorus stage Image 3<br />

Fitting of the agitators into the activated sludge stage Image 4<br />

Installation of the turbines Photos: WTE Image 5<br />

3-stage biological line Image 6<br />

sedimentation structure. From secondary<br />

sedimentation, the purified wastewater<br />

flows into the discharge channel, which<br />

leads to the discharge structure. From the<br />

discharge structure, the water is piped into<br />

the Ayamama or into the Sea of Marmara.<br />

Sludge treatment,<br />

sludge transport<br />

Sludge treatment essentially involves the<br />

following steps: sludge pre-thickening,<br />

sludge stabilisation by anaerobic treatment,<br />

i.e. digestion and subsequent mechanical<br />

<strong>de</strong>watering and drying.The excess sludge<br />

from secondary sedimentation flows<br />

through nine sludge thickeners (centrifuges<br />

each with a capacity of 76 m 3 /h) and is then<br />

kept in the raw sludge containers.<br />

The centrifuges increase the dried matter<br />

content of the sludge to 6%. The pre-thickened<br />

sludge then is pumped using six raw<br />

sludge pumps (capacity 115 m 3 /h) to the digestion<br />

tanks. The six digestion towers are<br />

ma<strong>de</strong> of cylindrical reinforced concrete and<br />

each have a capacity of 10,000 m 3 . Here, the<br />

pre-thickened raw sludge is anaerobically<br />

stabilised, while at the same time biogas is<br />

produced and the volume of the sludge reduced.<br />

The anaerobically stabilised sludge from the<br />

digestion towers is stored in sludge storage<br />

containers with a capacity of 20,000 m3. The<br />

sludge is then transported using six sludge<br />

pumps, each with a capacity of 38 m3/h, to<br />

the sludge <strong>de</strong>watering unit. The fully digested<br />

sludge is <strong>de</strong>watered using six centrifuges.<br />

The dried matter content of the fully<br />

digested sludge is increased to 25%.<br />

The biogas is stored in 2 gas tanks, each<br />

with a capacity of 4,000 m 3 , and subsequently<br />

converted in cogeneration into<br />

thermal and electrical energy which is used<br />

in the wastewater treatment plant. The gas<br />

10 INTERNATIONAL<br />

2011

turbine system allows for the operation of<br />

natural gas and biogas. The excess biogas<br />

capacity is burned off.<br />

To reduce the disposal costs of the <strong>de</strong>watered<br />

sludge, a drying plant was installed<br />

directly after the <strong>de</strong>watering units. A significant<br />

increase in the dried matter content<br />

in the outgoing sludge mixture (to approximately<br />

≥ 90%) was achieved.<br />

Service building, plant control<br />

The wastewater treatment plant is controlled<br />

and monitored from the control room in the<br />

service building. With the assistance of the<br />

process control system, the wastewater<br />

treatment plant is operated automatically.<br />

The use of automation systems is <strong>de</strong>signed<br />

to achieve the following goals for the Ataköy<br />

wastewater treatment plant:<br />

❙ Optimisation of the process cycle<br />

❙ Increase in plant safety<br />

❙ Optimisation of energy use<br />

❙ Reduction in personnel <strong>de</strong>ployed<br />

Wastewater treatment plant automation has<br />

been achieved through <strong>de</strong>centralised programmable<br />

logic controllers (PLC). In addition<br />

to its high level of operational safety<br />

and ease of handling, this solution enables<br />

flexible responses and allows complex functions<br />

to be performed.<br />

n addition, a laboratory in the service building<br />

is equipped for the necessary measurement<br />

analyses.<br />

Energy generation through gas<br />

turbines/cogeneration<br />

Instead of the wi<strong>de</strong>ly installed combined<br />

heat and power units for generating energy<br />

from fermentation gas, ISKI invited ten<strong>de</strong>rs<br />

for gas turbines. The biogas generated in the<br />

digestion towers is converted in cogeneration<br />

into thermal and electrical energy<br />

which is used in the wastewater treatment<br />

plant. The gas turbine system generates 2 x<br />

4.6 MW of electrical energy and allows for<br />

the operation of natural gas or biogas.<br />

Thanks to fermentation gas recovery, up to<br />

78% of the entire energy needs of the wastewater<br />

treatment plant can be met.<br />

Further special features<br />

Part of the purified wastewater from secondary<br />

sedimentation is piped from the<br />

discharge channel to the process water<br />

pumping station featuring a membrane filter<br />

plant, which has a capacity of 390 m3/h for<br />

process water and cooling water. Following<br />

treatment in the disinfection plant, the process<br />

water is ma<strong>de</strong> available for operating<br />

the wastewater treatment plant.<br />

For further discharged air treatment, including<br />

from the screen building, sludge treatment<br />

building and other structures handling<br />

discharged air, an ozone washing system is<br />

installed. The discharged air is treated at a<br />

rate of approximately 75,000 Nm 3 /h.<br />

<strong>wwt</strong>-<strong>international</strong>.com<br />

Operating concept<br />

The operating concept of the Ataköy wastewater<br />

treatment plant provi<strong>de</strong>s for threeshift<br />

operation.<br />

Altogether, approximately 65 staff ensure<br />

the professional operation of the plant,<br />

among them 4 engineers, 6 foremen, 16<br />

skilled workers and 2 secretaries. The company’s<br />

own guard service is responsible for<br />

the security of the plant. The operating staff<br />

of WTE and the consortium partners were<br />

trained both in the <strong>international</strong> training<br />

centre of the WTE operating company and<br />

on site.<br />

Conclusion<br />

From the viewpoint of the consortium partners,<br />

a positive conclusion can be drawn. All<br />

the partners pulled together to bring the<br />

Sewage systems<br />

project to a successful conclusion and to<br />

satisfy ISKI, the customer. This goal has<br />

clearly been achieved.<br />

For the region of Istanbul and the surrounding<br />

waterways, an enormously important<br />

step has been taken to improve living conditions.<br />

CONTACT<br />

Jens-O. QUADT (Gra duate in Business Economics<br />

– Management and Business Aca<strong>de</strong>my)<br />

Head of IMS and Central Services Department<br />

WTE Wassertechnik GmbH<br />

Ruhrallee 185 | 45136 Essen | Germany<br />

Phone: +49/201 8968 – 559<br />

Fax: +49/201 8968 – 560<br />

E-mail: jens.quadt@wte.<strong>de</strong><br />

Internet www.wte.<strong>de</strong><br />

11

WASTEWATER Discharge and treatment<br />

Dipl.-Ing. Bernhard HEINE<br />

Wastewater master<br />

plan for Bahrain<br />

Bahrain’s continuing urbanisation<br />

has ma<strong>de</strong> it necessary to completely<br />

mo<strong>de</strong>rnise its supply and disposal<br />

infrastructure.<br />

In August 2008, the Gesellschaft für Technische<br />

Zusammenarbeit (GTZ), in cooperation<br />

with Dornier Consulting, was<br />

awar<strong>de</strong>d a contract to <strong>de</strong>velop a wastewater<br />

master plan for the Kingdom of Bahrain.<br />

Over a period of 18 months, a comprehensive<br />

needs analysis and a forecast plan for<br />

the next 20 years were <strong>de</strong>veloped – a wastewater<br />

infrastructure plan.<br />

The plan inclu<strong>de</strong>d the following <strong>de</strong>tails:<br />

❙ Wastewater canal system<br />

❙ Rainwater canal system<br />

❙ Wastewater treatment plants<br />

❙ Utilisation of purified wastewater (Treated<br />

Sewage Effluent, TSE)<br />

❙ Use of sludge<br />

❙ Environmental impact assessment<br />

❙ Organisation analysis<br />

Owing to rapidly increasing urbanisation in<br />

the Kingdom of Bahrain and the population<br />

The island state of Bahrain<br />

The Kingdom of Bahrain is an island state<br />

comprising 33 islands in an inlet of the<br />

Persian Gulf, east of Saudi Arabia and<br />

west of Qatar. With an area of approximately<br />

711 km² – following artificial<br />

land reclamation – the archipelago is not<br />

quite as large as Middlesex. In Arabic the<br />

name Bahrain means “two seas”. Bahrain<br />

has a population of a little over 1 million.<br />

Bahrain is one of the most economically<br />

advanced of the Gulf states. Diminishing<br />

reserves mean that the end of oil production<br />

(since 1932) is in sight. The processing<br />

industry will therefore gain increasing<br />

economic importance. The oil<br />

refinery in Sitra, which has been operational<br />

since 1936, now processes cru<strong>de</strong><br />

oil mainly from Saudi Arabia. The petrochemical<br />

and aluminium industries are<br />

based on natural gas. The pig iron reduction<br />

plants as well as the electricity<br />

and <strong>de</strong>salination plants are also run on<br />

the still readily available natural gas.<br />

Bahrain is a leading financial centre in<br />

the Arabian Gulf region. Its agriculture<br />

(1,000 ha) produces vegetables, poultry,<br />

eggs, milk and fruit. Bahrain is becoming<br />

increasing popular among tourists from<br />

Saudi Arabia, as well as from all over the<br />

world.<br />

Sources: Wikipedia.<strong>de</strong> [translated]<br />

Bibliographisches Institut &<br />

F. A. Brockhaus AG, 2009<br />

12 INTERNATIONAL<br />

2011

BAHRAIN: the planning area Image 1<br />

growth that accompanied it, the need arose<br />

for a basic infrastructure in the wastewater<br />

disposal sector (Images 1 – 3).<br />

Wastewater canal system<br />

The existing wastewater system is about<br />

2,400 km long, including the main and<br />

branch sewers and approximately 500 pump<br />

stations.<br />

Large sections of the existing system are<br />

overloa<strong>de</strong>d and too small for the amounts of<br />

wastewater currently being produced. As a<br />

result, hydraulic efficiency is in an extremely<br />

precarious condition and the risk of<br />

flooding is high.<br />

Discharge measurements were carried out<br />

at central points of the system to <strong>de</strong>termine<br />

the amount of infiltration water. An average<br />

infiltration rate of 50 % was found, a figure<br />

that was attributed to pipes being laid incorrectly<br />

during construction, and in some<br />

cases the wrong type of material being<br />

chosen. This is an extremely high value<br />

which, in the midterm, can only be reduced<br />

Discharge and treatment<br />

by means of technical pipe rehabilitation. In<br />

addition, the wastewater system also requires<br />

extensive installation of extension<br />

and bypass channels.<br />

Rainwater canal system<br />

The rainwater system is approximately<br />

450 km long and has a total of 69 pump stations.<br />

Image 2<br />

Population<br />

growth 2001 to<br />

2030<br />

<strong>wwt</strong>-<strong>international</strong>.com INTERNATIONAL<br />

13

WASTE WATER Discharge and treatment<br />

TSE avaible TSE <strong>de</strong>mand<br />

18000000<br />

m3 /month<br />

14000000<br />

12000000<br />

10000000<br />

8000000<br />

6000000<br />

Surplus<br />

4000000<br />

2000000<br />

Crop <strong>de</strong>mand covered<br />

0<br />

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec<br />

Month<br />

To prepare a mo<strong>de</strong>l of the rainwater system,<br />

some additional measurements had to be<br />

ma<strong>de</strong> and the existing files completed and<br />

brought up to date. The analysis of the rainwater<br />

system covered a total of 30 separate<br />

catchment areas. The reason for mo<strong>de</strong>lling<br />

the rainwater system was twofold: firstly, it<br />

was necessary to test the hydraulic efficiency<br />

of the system and <strong>de</strong>termine the risk<br />

of flooding; secondly, it was also necessary<br />

to simulate precipitation events in or<strong>de</strong>r to<br />

generate precipitation discharge mo<strong>de</strong>ls for<br />

Bahrain. Before this type of hydraulic mo<strong>de</strong>l<br />

can provi<strong>de</strong> precise data, the system has to<br />

be calibrated by means of discharge measurements.<br />

Table 1 shows the planning parameters<br />

for the calculation of the mo<strong>de</strong>l.<br />

The existing rainwater canal system is a<br />

gravity line system that discharges in the<br />

direction of the seacoast. High water pump<br />

stations at the outlet in the area of the coast<br />

ensure unhin<strong>de</strong>red discharge even during<br />

high water. The poor condition of the entire<br />

system has become apparent owing to the<br />

high dry weather flows and the high infiltration<br />

caused by it.<br />

Image 3<br />

Increases in<br />

wastewater<br />

2008 to 2030<br />

Image 4<br />

Increase in<br />

wastewater<br />

treatment<br />

capacities<br />

in m3 /d<br />

Image 5<br />

Reuse of<br />

wastewater in<br />

Bahrain 2020<br />

Image 6<br />

Sludge treatment in Bahrain<br />

Wastewater treatment plants<br />

The country’s rapidly growing urbanisation<br />

has raised the capacity of wastewater treatment<br />

plants in the highly populated areas<br />

(Image 4). The Kingdom of Bahrain currently<br />

has 11 wastewater treatment plants,<br />

the main ones being the Tubli and North<br />

Sitra plants.<br />

The other plants are in the less <strong>de</strong>nsely<br />

populated areas in the east and west of Bahrain.<br />

Tubli is the largest wastewater treatment<br />

plant and with a capacity of around 200,000<br />

m3/d is therefore hugely overbur<strong>de</strong>ned.<br />

In future, wastewater disposal from the<br />

Muharraq peninsula will take place through<br />

a new wastewater treatment plant. This new<br />

plant is currently in the ten<strong>de</strong>ring phase.<br />

The plan for i<strong>de</strong>al wastewater treatment<br />

capacities is to be achieved predominantly<br />

through the following key measures:<br />

❙ Renovation, extension and mo<strong>de</strong>rnisation<br />

of the existing main wastewater treatment<br />

plant in Tubli<br />

❙ Construction of the new Muharraq wastewater<br />

treatment plant<br />

Reusing purified wastewater<br />

The reuse of purified wastewater is an important<br />

factor in a country with few natural<br />

water resources (Image 5).<br />

The system for reusing wastewater (TSE) is<br />

<strong>de</strong>signed solely for the irrigation of agricultural<br />

and green areas. The system comprises:<br />

❙ conditioning stage with sand filtering and<br />

treatment with bacteria<br />

❙ reservoirs and<br />

❙ the transport and distribution pipes<br />

14 INTERNATIONAL<br />

2011

Image 7<br />

Sludge management plan<br />

Demonstation trials<br />

and marketing<br />

Demonstation trials<br />

and marketing<br />

Total Cost (Mil. BHD)<br />

Treated sewage effluent system Sludge reuse system<br />

59.17<br />

Sewage teatmant works<br />

147.19<br />

No<br />

No<br />

Yes<br />

Yes<br />

Yes<br />

Do farmers accept<br />

use of sludge?<br />

Yes<br />

Is <strong>de</strong>mand sufficient<br />

to use all sludge?<br />

No<br />

Do parks accept<br />

use of sludge?<br />

Yes<br />

Is <strong>de</strong>mand sufficient<br />

to use all sludge?<br />

No<br />

Bahrain currently has three pipe systems for<br />

reusing purified wastewater, all of which<br />

operate in<strong>de</strong>pen<strong>de</strong>ntly of each other.<br />

The main network uses treated wastewater<br />

from the Tubli treatment plant.<br />

Bahrain sludge<br />

Does quality comply<br />

with standards?<br />

No<br />

Can sludge quality<br />

be improved?<br />

Do the standards<br />

need revising?<br />

Yes<br />

Yes<br />

Transport sludge to outlet<br />

No<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

0.5<br />

Foul sewerage system<br />

211.47<br />

Surface water drainage system<br />

38.93<br />

Control industrial<br />

effluent discharges<br />

No<br />

Can cement factory<br />

use sludge as fuel?<br />

Co-treatment with<br />

solid waste?<br />

Is landfill disposal<br />

site available?<br />

Install <strong>de</strong>dicated<br />

sludge incinerator<br />

Image 8<br />

Project costs<br />

Rainwater discharge parameters Table 1<br />

Protection class Recommen<strong>de</strong>d (Rain R1) Medium (Rain R2) High (Rain R5)<br />

Return period 1 2 5<br />

Duration (min) 60 30 30<br />

Intensity (mm/hr) 11.5 24 38<br />

Total rainfall (mm) 11.5 13 19<br />

Increases in amounts of sludge Table 2<br />

STP 2008 2013 2015 2020 2025 2030<br />

WPCC Tubli 20,836 22,197 23,694 26,090 28,192 29,588<br />

STP<br />

Muharraq<br />

0 7,551 8,368 10,246 11,780 12,832<br />

STP NBNT 0 695 776 1,098 1,353 1,545<br />

STP<br />

South-West<br />

0 0 0 1,235 1,648 2,058<br />

STP<br />

South-West<br />

0 1,389 1,340 1,236 1,120 993<br />

Total 20,836 31,832 34,178 39,905 44,093 47,016<br />

A TSE network is also being planned for the<br />

new Muharraq wastewater treatment plant.<br />

Both the <strong>de</strong>centralised and the central system<br />

can be used for TSE treatment:<br />

Discharge and treatment<br />

Decentralised supply system<br />

❙ production – transport – storage – distribution<br />

– end user<br />

The features are: continuous transport via<br />

gravity line, low-pressure line systems, pressure<br />

pipe systems to the end user<br />

The advantages.<br />

❙ smaller dimension of pipes in the transport<br />

lines<br />

❙ the pressure in the distribution lines can<br />

be used for various areas<br />

Central supply system<br />

❙ production – storage – distribution – utilisation<br />

The advantages.<br />

❙ reservoirs and pump stations do not have<br />

to be in remote locations<br />

The TSE systems must perform the following<br />

operations:<br />

❙ the efficient use of purified wastewater<br />

❙ valuable resource and therefore an integral<br />

component of water management planning<br />

❙ conserve groundwater resources<br />

❙ provi<strong>de</strong> water for industrial use when<br />

there is no requirement for drinking water.<br />

Image 5 shows the TSE usage balance<br />

forecast for 2020.<br />

Sludge treatment<br />

Sludge is currently treated at the location of<br />

the wastewater treatment plants (Image 6).<br />

The first stage of biological sludge treatment<br />

is aerobic digestion. This is followed by<br />

<strong>de</strong>hydration in a sludge drying bed. A thermal<br />

sludge drying plant with preliminary<br />

mechanical <strong>de</strong>hydration is installed at the<br />

treatment plant in Tubli. Due to technical<br />

problems, currently only 37 tons TS/a of<br />

sludge are being treated and supplied to<br />

agriculture, for soil enrichment, as well as<br />

to a landfill. A long-term sludge management<br />

plan has been <strong>de</strong>veloped as part of this<br />

master plan (image 7).<br />

In response to the continued rise in the<br />

population <strong>de</strong>nsity and the increased amount<br />

of approximately 47,000 tons TS/a sludge<br />

associated with this, long-term thermal use<br />

is un<strong>de</strong>r discussion.<br />

The costs<br />

The proposals put forward in this wastewater<br />

master plan would require investments in<br />

the region of EUR 900 million in the 20<br />

years un<strong>de</strong>r review; based on the forecasted<br />

population growth, this is approximately<br />

EUR 360 per inhabitant (image 8).<br />

<strong>wwt</strong>-<strong>international</strong>.com INTERNATIONAL<br />

No<br />

No<br />

No<br />

CONTACT<br />

Dipl.-Ing. Bernhard HEINE<br />

Ing.-Büro H. Voessing GmbH<br />

NL Frankfurt<br />

Hahnstraße 43 E | D – 60528 Frankfurt/Main<br />

15

INDUSTRIAL WATER Mo<strong>de</strong>rn methods<br />

Elmar BILLENKAMP<br />

Water and wastewater<br />

treatment for<br />

Solar industry<br />

Industrial wastewater is becoming<br />

more and more important to<br />

preserve resources.<br />

Solar cells are manufactured in a complex process Image 1<br />

Solar cells are manufactured in a complex<br />

process that requires enormous<br />

know-how. The objective is to produce<br />

panels with a high level of efficiency at low<br />

cost. To achieve this, different production<br />

processes are used. A fundamental distinction<br />

is ma<strong>de</strong> between solar cells on the basis<br />

of silicon wafers and thin-film cells, in<br />

which a special process is used to apply the<br />

photovoltaic layer onto a carrier medium.<br />

The manufacturers of solar cells are constantly<br />

<strong>de</strong>veloping and improving the production<br />

processes.<br />

For all methods, large quantities of water are<br />

required. The production process leads to<br />

polluted wastewater. Since water is becoming<br />

increasingly valuable as a raw material,<br />

efficient water management is necessary.<br />

The wastewater from the production process<br />

must be treated in such a way that as much<br />

water as possible can be recycled. The<br />

treated wastewater must reliably comply<br />

with the discharge parameters so that it can<br />

be discharged without polluting the environment.<br />

Besi<strong>de</strong>s optimisation of the production<br />

process, optimisation of the wastewater<br />

treatment is often necessary. This is why<br />

EnviroChemie is conducting intensive research<br />

to continuously <strong>de</strong>velop the process<br />

and thus to significantly increase water recycling<br />

rates. For this reason, the entire<br />

production process has to be taken into account<br />

in or<strong>de</strong>r to achieve not only “end of<br />

the pipe” solutions, but also to offer production-integrated<br />

solutions.<br />

In Germany, the standards for wastewater<br />

treatment are high. They are laid down in<br />

Appendix 54 of the Wastewater Ordinance<br />

(AbwV). This appendix applies for wastewater<br />

whose contaminant load originates pri-<br />

marily from the production of semi-conductor<br />

components and solar cells, including the<br />

related pretreatment, intermediate treatment<br />

and after-treatment. In addition, local statutes<br />

laid down by local authorities and<br />

towns must also be complied with. These<br />

frequently lay down further requirements<br />

<strong>de</strong>pending on the capacity of the local municipal<br />

sewage treatment plant and the previous<br />

pollution of the outfall (river) into<br />

which the sewage treatment plant discharges<br />

the treated wastewater.<br />

The concepts also require that safety engineering<br />

should meet special standards. An<br />

example here is the formation of hydrogen<br />

from alkaline wastewater when silicon from<br />

wafer production is dissolved. Coordinated<br />

measures are required here for explosion<br />

prevention and protection.<br />

Fluori<strong>de</strong> is created in the production process<br />

as hydrofluoric acid HF. The handling of<br />

hydrofluoric acid requires special precautions,<br />

since this substance is extremely toxic<br />

and aggressive, and contact with even small<br />

quantities can have fatal consequences.<br />

These basic requirements must be met in all<br />

projects worldwi<strong>de</strong>.<br />

In the following, three examples will be<br />

used to show the continuing innovative<br />

water and wastewater treatment in the solar<br />

industry. The examples are not only current<br />

projects, but also processes from the field of<br />

research and <strong>de</strong>velopment.<br />

Solar cell production in India<br />

In the past few years, the production of<br />

wafers and cells has increasingly been transferred<br />

abroad. In some cases, the requirements<br />

for the treated wastewater differ from<br />

those in Germany. One example of this is<br />

India.<br />

In India, ground and surface water naturally<br />

have a high concentration of fluori<strong>de</strong>. In the<br />

state of Rajasthan, almost all districts have<br />

high fluori<strong>de</strong> concentrations (up to 18 ppm)<br />

in their drinking/ground water sources. In<br />

southern Rajasthan, the concentrations of<br />

fluori<strong>de</strong> are up to 11 ppm (for comparison,<br />

in Germany the fluori<strong>de</strong> concentration is<br />

only 0.3 ppm). These high concentrations<br />

Residual concentration of Image 2<br />

fluori<strong>de</strong> and pH-value <strong>de</strong>pending<br />

on the addition of CaOH 2 /1/<br />

16 INTERNATIONAL<br />

2011<br />

1000<br />

F-<br />

mg<br />

100<br />

10<br />

F – concentration<br />

pH value<br />

1 0 10 20 30 ml/l 50<br />

Ca(OH) 2 10 % suspension<br />

2<br />

4<br />

6<br />

8<br />

10<br />

12<br />

pH value

Diagrammatic view of the anaerobic Biomar ® process<br />

can be harmful to people and cause chronic<br />

fluori<strong>de</strong> intoxication (fluorosis). The legal<br />

regulations are therefore strict in terms of<br />

fluori<strong>de</strong> in treated waters. (Quelle??)<br />

Indian law:<br />

The fluori<strong>de</strong> limit concentration as F in<br />

treated effluent quality of common effluent<br />

treatment plants into inland surface waters<br />

is 2 mg/l.<br />

In Germany, the usual limit value applicable<br />

for fluori<strong>de</strong> is 50 mg/l. The requirement of<br />

< 2 mg fluori<strong>de</strong>/l requires further process<br />

technologies. A relevant procedure (Envochem<br />

Sorp F) has been <strong>de</strong>veloped and tested<br />

by EnviroChemie.<br />

Fluori<strong>de</strong> precipitation through<br />

Envochem ® COL L technology<br />

Wastewaters containing fluori<strong>de</strong>s are usually<br />

treated by neutralisation with lime and<br />

precipitation of fluori<strong>de</strong> as calcium fluori<strong>de</strong><br />

according to equation 1.<br />

Ca(OH) 2 + 2 HF CaF 2 + 2 H 2 O Eq. 1<br />

In practice, final fluori<strong>de</strong> concentrations of<br />

about 20 mg/l to 30 mg/l can be achieved<br />

with Envochem ® COL L technology. This is<br />

in line with literature results (Image 2).<br />

Envochem ® SORP F process<br />

Envochem ® SORP F is a continuously operating<br />

wastewater treatment process for<br />

cleaning industrial wastewater containing<br />

fluori<strong>de</strong> based on the <strong>de</strong>ep bed filtration /<br />

adsorption principle. The elimination of<br />

fluori<strong>de</strong> takes place in a three-stage filtra-<br />

tion unit with automated filters (Image 3).<br />

The filters are filled with various special<br />

filter materials. The final filter material is<br />

doped for optimal adsorption of fluori<strong>de</strong>.<br />

Image 4 below shows the results of a longterm<br />

run of the Envochem ® adsorption unit.<br />

For more than 120 bed volumes, the incoming<br />

fluori<strong>de</strong> concentration is reduced to a<br />

constantly low effluent level (almost without<br />

being influenced by feed concentration).<br />

Fluori<strong>de</strong> concentration in feed and discharge<br />

is shown as a normalised value. A maximum<br />

elimination of more than 75% is reached.<br />

After exhaustion of the adsorption capacity,<br />

a sud<strong>de</strong>n increase in the discharge concentration<br />

can be seen. After regeneration of the<br />

adsorber, effluent quality is re-established.<br />

“Zero discharge” concept<br />

As already mentioned, the production of<br />

solar cells is increasingly being transferred<br />

Fluori<strong>de</strong> (C F– /C Norm ) [–]<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

Feed filter<br />

Discharge adsorber<br />

Image 7<br />

0 20 40 60 80 100 120 140 160<br />

Feed volume (VFeed /VAdsorber ) [–]<br />

Mo<strong>de</strong>rn methods<br />

to countries in which the cells produced can<br />

also be effectively used on account of intensive<br />

solar radiation. In these countries (in<br />

southern Europe, for example), there is often<br />

a severe shortage of water. For this reason,<br />

concepts for water recycling, going as far as<br />

“zero discharge”, are sensible and cost-effective<br />

there.<br />

Such a concept has been <strong>de</strong>vised for a customer.<br />

From river water treatment to recirculation,<br />

a complete process for water<br />

management with “zero discharge” criteria<br />

was <strong>de</strong>veloped. The important thing is<br />

knowledge of the production process in or<strong>de</strong>r<br />

to be able to close the circuit. The production<br />

in question is a wafer and cell production<br />

system (Image 5). In the case in<br />

question, the wastewater is classified according<br />

to the following criteria:<br />

❙ Sanitary wastewater from the administration<br />

<strong>de</strong>partment<br />

❙ Organically contaminated rinse water<br />

from wafer production<br />

❙ Inorganically contaminated concentrates<br />

from cell production<br />

❙ Inorganically contaminated rinse water.<br />

The weakly contaminated rinse water is<br />

treated by means of reverse osmosis after<br />

appropriate conditioning. The permeate is<br />

fed back before the water treatment plant for<br />

high-purity production water. This makes it<br />

possible to save consi<strong>de</strong>rable quantities of<br />

water.<br />

The concentrates from the reverse osmosis<br />

as well as all other wastewater are treated in<br />

the chemical-physical treatment plant of the<br />

Envochemâ Col type. Uniform inflow conditions<br />

are important for stable functioning.<br />

For this reason, concentrates (discontinuously<br />

discharged or rejected treatment<br />

baths) are collected separately and then<br />

dosed. The pretreated inorganic wastewater<br />

is then evaporated. All organically contaminated<br />

wastewater is then subjected to an<br />

aerobic Biomarâ type biological treatment.<br />

The cleaned wastewater treated in this way<br />

is prepared using a membrane technology<br />

until it can be used in the cooling tower.<br />

Energy from wastewater<br />

It is possible to produce energy from wastewater<br />

from the production of solar cells, on<br />

Image 4<br />

Further reduction<br />

of fluori<strong>de</strong> through<br />

adsorption<br />

<strong>wwt</strong>-<strong>international</strong>.com INTERNATIONAL<br />

17

INDUSTRIAL WATER Mo<strong>de</strong>rn methods<br />

Cooling<br />

tower<br />

River<br />

Air<br />

Bleed<br />

Water<br />

treatmant<br />

Sludge<br />

Office<br />

Concentrate<br />

pre-treatmant<br />

Biological<br />

treatment<br />

Biomar ®<br />

Envopur<br />

reverse<br />

osmosis<br />

Complete process for water management Image 5<br />

the basis of crystalline silicon. These cells<br />

currently have the highest efficiency level,<br />

but are more expensive than solar cells produced<br />

on the basis of thin film technology<br />

on account of the raw material silicon and<br />

the more elaborate manufacturing process.<br />

In the course of the entire manufacturing<br />

chain, the first wastewater accumulates during<br />

the sawing of the mono silicon wafers.<br />

The individual thin silicon wafers are sawn<br />

from one mono silicon crystal. The aim is to<br />

produce wafers that are as thin as possible<br />

with a minimum of sawing loss. To cool the<br />

saws and ensure effective cutting, large<br />

quantities of water are used, or else mixtures<br />

of polyethylene glycol (PEG) and silicon<br />

carbi<strong>de</strong> (Novak, 2011). Here the objective of<br />

the wastewater treatment is to keep the water<br />

in circulation and to treat it in such a way<br />

High pure<br />

water production<br />

Water<br />

production<br />

Chemical<br />

Rins water<br />

treatmant<br />

Solids<br />

Concentrate<br />

Chemical<br />

Concentrate<br />

pre-treatmant<br />

Envochem ®<br />

evaporator<br />

Concentrate<br />

Water treatment Production<br />

Waste water treatment<br />

Cell<br />

production<br />

Concentrate<br />

Rins water<br />

treatmant/<br />

Envopur<br />

reverse<br />

osmosis<br />

Image 6<br />

Anaerobic<br />

<strong>de</strong>gradation<br />

of PEG and<br />

corresponding<br />

volumetric loading<br />

that it can be discharged. A particular challenge<br />

is the dissolved PEG, which remains<br />

in the wastewater. Depending on the chain<br />

length, PEG is only bio<strong>de</strong>gradable after a<br />