CT4860 STRUCTURAL DESIGN OF PAVEMENTS

CT4860 STRUCTURAL DESIGN OF PAVEMENTS

CT4860 STRUCTURAL DESIGN OF PAVEMENTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

on motorways where it is government policy to apply ‘silent roads’ which<br />

means in practice a wearing course of porous asphalt (‘ZOAB’). The fine<br />

cracks in the reinforced concrete pavement prevent ZOAB for reflective<br />

cracking.<br />

Below the reinforced concrete pavement a 50 to 60 mm thick asphalt layer is<br />

applied. The reasons for this are:<br />

- the asphalt layer has a very good resistance against erosion which is<br />

essential for a good structural behaviour of the concrete pavement;<br />

- the asphalt layer provides a very uniform friction with the overlying<br />

reinforced concrete layer which is favorable for the development of a<br />

regular pattern of fine cracks in the concrete layer;<br />

- the surface of the asphalt layer is very even which results in a constant<br />

thickness of the concrete later and that is also favorable for the<br />

development of a regular pattern of fine cracks in the concrete layer;<br />

- in the case that a cement-bound base is applied the asphalt layer acts as<br />

an anti-reflective layer.<br />

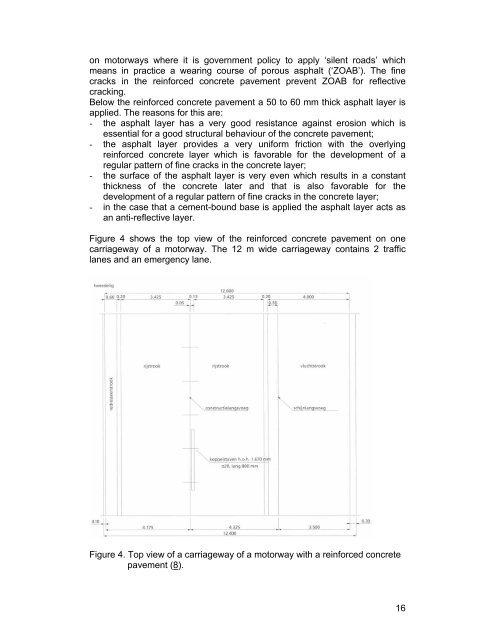

Figure 4 shows the top view of the reinforced concrete pavement on one<br />

carriageway of a motorway. The 12 m wide carriageway contains 2 traffic<br />

lanes and an emergency lane.<br />

Figure 4. Top view of a carriageway of a motorway with a reinforced concrete<br />

pavement (8).<br />

16