Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

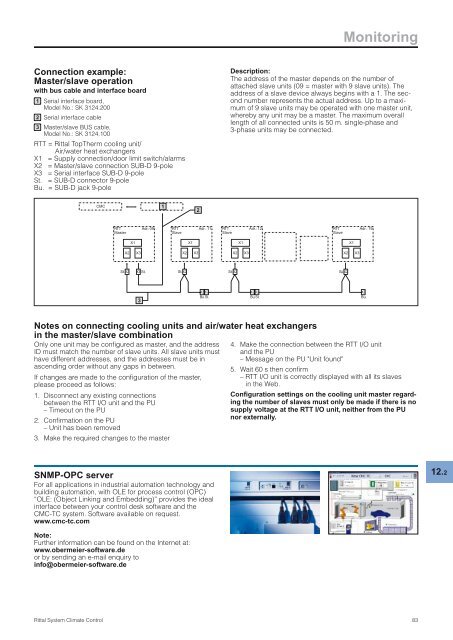

Connection example:<br />

Master/slave operation<br />

with bus cable and interface board<br />

1 Serial interface board,<br />

Model No.: <strong>SK</strong> 3124.200<br />

2 Serial interface cable<br />

3 Master/slave BUS cable,<br />

Model No.: <strong>SK</strong> 3124.100<br />

RTT = <strong>Rittal</strong> TopTherm cooling unit/<br />

Air/water heat exchangers<br />

X1 = Supply connection/door limit switch/alarms<br />

X2 = Master/slave connection SUB-D 9-pole<br />

X3 = Serial interface SUB-D 9-pole<br />

St. = SUB-D connector 9-pole<br />

Bu. = SUB-D jack 9-pole<br />

CMC<br />

<strong>Rittal</strong> <strong>System</strong> <strong>Climate</strong> <strong>Control</strong><br />

RTT<br />

Master<br />

X1<br />

X2 X3<br />

Adr.: 09<br />

RTT<br />

Slave<br />

X1<br />

X2 X3<br />

Adr.: 11<br />

St. X2 X3 St. St. X2<br />

St. X2<br />

3<br />

1<br />

2<br />

RTT<br />

Slave<br />

Monitoring<br />

Description:<br />

The address of the master depends on the number of<br />

attached slave units (09 = master with 9 slave units). The<br />

address of a slave device always begins with a 1. The second<br />

number represents the actual address. Up to a maximum<br />

of 9 slave units may be operated with one master unit,<br />

whereby any unit may be a master. The maximum overall<br />

length of all connected units is 50 m. single-phase and<br />

3-phase units may be connected.<br />

X1<br />

X2 X3<br />

Adr.: 12<br />

RTT<br />

Slave<br />

St. X2<br />

X1<br />

X2 X3<br />

X2 X2 X2 X2<br />

X2<br />

Bu. St.<br />

Bu. St.<br />

Bu.<br />

Notes on connecting cooling units and air/water heat exchangers<br />

in the master/slave combination<br />

Only one unit may be configured as master, and the address<br />

ID must match the number of slave units. All slave units must<br />

have different addresses, and the addresses must be in<br />

ascending order without any gaps in between.<br />

If changes are made to the configuration of the master,<br />

please proceed as follows:<br />

1. Disconnect any existing connections<br />

between the RTT I/O unit and the PU<br />

<strong>–</strong> Timeout on the PU<br />

2. Confirmation on the PU<br />

<strong>–</strong> Unit has been removed<br />

3. Make the required changes to the master<br />

SNMP-OPC server<br />

For all applications in industrial automation technology and<br />

building automation, with OLE for process control (OPC)<br />

“OLE: (Object Linking and Embedding)” provides the ideal<br />

interface between your control desk software and the<br />

CMC-TC system. Software available on request.<br />

www.cmc-tc.com<br />

Note:<br />

Further information can be found on the Internet at:<br />

www.obermeier-software.de<br />

or by sending an e-mail enquiry to<br />

info@obermeier-software.de<br />

Adr.: 19<br />

4. Make the connection between the RTT I/O unit<br />

and the PU<br />

<strong>–</strong> Message on the PU "Unit found"<br />

5. Wait 60 s then confirm<br />

<strong>–</strong> RTT I/O unit is correctly displayed with all its slaves<br />

in the Web.<br />

Configuration settings on the cooling unit master regarding<br />

the number of slaves must only be made if there is no<br />

supply voltage at the RTT I/O unit, neither from the PU<br />

nor externally.<br />

83<br />

12.2