- Page 1 and 2:

Aggregati Manuale d’uso e manuten

- Page 3 and 4:

Informazioni sulla pubblicazione/ P

- Page 5 and 6:

MC S.r.l. © - 01ih00a.fm271107 Ita

- Page 7 and 8:

Italiano I

- Page 9 and 10:

Indice Introduzione Descrizione 1 P

- Page 11 and 12:

Interventi 6 Manutenzione Indice 6.

- Page 13 and 14:

Introduzione Scopo e limiti del man

- Page 15 and 16:

Descrizione I

- Page 17 and 18:

1 Parti principali 1.1 Destinazione

- Page 19 and 20:

1.3 Interfaccia aggregato-utensile

- Page 21 and 22:

1.3.4 Attacco lama e pinza Attacco

- Page 23 and 24:

1.5 Convenzioni Si definisce il ver

- Page 25 and 26:

2 Preparazione 2.1 Installazione de

- Page 27 and 28:

2.2 Montaggio della flangia sull’

- Page 29 and 30:

Utilizzazione I

- Page 31 and 32:

MC S.r.l. © - 0103h00a.fm141207 3

- Page 33 and 34:

3.3 Utensili per taglio 3.3.1 Flang

- Page 35 and 36:

MC S.r.l. © - 0103h00a.fm141207 3

- Page 37 and 38:

MC S.r.l. © - 0104h00a.fm141207 4

- Page 39 and 40:

4.3 Utensili per taglio 4.3.1 Flang

- Page 41 and 42:

4.3.3 Fissaggio a 6 viti Torx D 1.

- Page 43 and 44:

5 Regolazioni MC S.r.l. © - 0105h0

- Page 45 and 46:

MC S.r.l. © - 0105h00a.fm141207 5

- Page 47 and 48:

Interventi I

- Page 49 and 50:

6 Manutenzione 6 Manutenzione Duran

- Page 51 and 52:

6.3 Lubrificazione a grasso 6.3.1 P

- Page 53 and 54:

6.4.1 Verifica livello olio Attende

- Page 55 and 56:

Posizionarsi su una vaschetta di ra

- Page 57 and 58:

6.5 Pulizia A 6 Manutenzione Pulire

- Page 59 and 60:

Appendici I

- Page 61 and 62: A Informazioni sulla sicurezza A.1

- Page 63 and 64: MC S.r.l. © - 01ah00a.fm141207 A I

- Page 65 and 66: A.6 Segnaletica obblighi 6 Assicura

- Page 67 and 68: Indice analitico A aggregato docume

- Page 69 and 70: English GB

- Page 71 and 72: Table of contents Introduction Desc

- Page 73 and 74: Table of contents 6.5 Cleaning ....

- Page 75 and 76: Introduction Field of application a

- Page 77 and 78: Description GB

- Page 79 and 80: 1 Main parts 1.1 Designed use MC S.

- Page 81 and 82: 1.3 Aggregate-tool interface 1.3.1

- Page 83 and 84: 1.3.4 Blade mounting and collet Bla

- Page 85 and 86: 1.5 Conventions MC S.r.l. © - 0101

- Page 87 and 88: 2 Preparation 2.1 Fitting the aggre

- Page 89 and 90: MC S.r.l. © - 0102h00gb.fm110208 2

- Page 91 and 92: Uses GB

- Page 93 and 94: 3 Tool characteristics 3.1 Boring t

- Page 95 and 96: 3.3 Circular blade tools 3.3.1 Flan

- Page 97 and 98: 3.4 Safety in the choice of tools M

- Page 99 and 100: 4 Fitting tools MC S.r.l. © - 0104

- Page 101 and 102: 4.3 Cutting tools 4.3.1 Flange and

- Page 103 and 104: 4.3.3 6 torx screw mounting D 1. Un

- Page 105 and 106: 5 Adjustments MC S.r.l. © - 0105h0

- Page 107 and 108: 5.2 Transverse orientation (variati

- Page 109 and 110: Operations GB

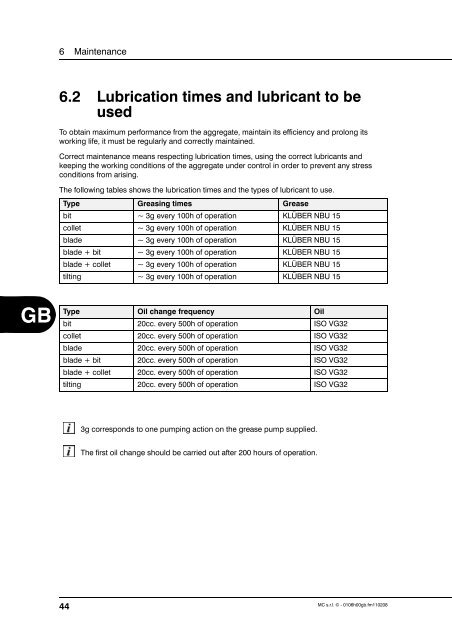

- Page 111: 6 Maintenance 6 Maintenance Do not

- Page 115 and 116: 6.4.1 Oil level check Wait for the

- Page 117 and 118: 6 Maintenance Place the aggregate o

- Page 119 and 120: 6.5 Cleaning 6 Maintenance Clean su

- Page 121 and 122: Appendices GB

- Page 123 and 124: A Safety informations A.1 Safety re

- Page 125 and 126: MC S.r.l. © - 01ah00gb.fm110208 A

- Page 127 and 128: A.6 Warning signs 6 Make 4 Turn 5 W

- Page 129 and 130: Analytical index A adjustment possi

- Page 131 and 132: Français F

- Page 133 and 134: Table des matières Introduction De

- Page 135 and 136: Interventions 6 Entretien Table des

- Page 137 and 138: Introduction But et limites de la n

- Page 139 and 140: Description F

- Page 141 and 142: 1 Parties principales 1.1 Destinati

- Page 143 and 144: 1.3 Interface agrégat-outil 1.3.1

- Page 145 and 146: 1.3.4 Prise lame et pince Prise lam

- Page 147 and 148: 1.5 Conventions On définit le sens

- Page 149 and 150: 2 Préparation 2.1 Installation de

- Page 151 and 152: MC S.r.l. © - 0102h00f.fm141207 2

- Page 153 and 154: Utilisation F

- Page 155 and 156: MC S.r.l. © - 0103h00f.fm141207 3

- Page 157 and 158: 3.3 Outils pour coupe 3.3.1 Flasque

- Page 159 and 160: 3.4 Sécurité sur le choix de l’

- Page 161 and 162: 4 Montage des outils MC S.r.l. © -

- Page 163 and 164:

4.3 Outils pour coupe 4.3.1 Flasque

- Page 165 and 166:

4.3.3 Fixation à 6 vis Torx D 1. D

- Page 167 and 168:

5 Réglages Toutes les opérations

- Page 169 and 170:

5.2 Orientation transversale (varia

- Page 171 and 172:

Interventions F

- Page 173 and 174:

6 Entretien 6 Entretien Pendant la

- Page 175 and 176:

6.3 Lubrification à la graisse 6.3

- Page 177 and 178:

6.4.1 Vérification du niveau d’h

- Page 179 and 180:

6 Entretien Placer un bac de récup

- Page 181 and 182:

6.5 Nettoyage Nettoyer les surfaces

- Page 183 and 184:

Appendices F

- Page 185 and 186:

MC S.r.l. © - 01ah00f.fm141207 A I

- Page 187 and 188:

MC S.r.l. © - 01ah00f.fm141207 A I

- Page 189 and 190:

A.6 Signaux d’obligation 6 Veille

- Page 191 and 192:

Index analytique A agrégat montage

- Page 193 and 194:

Deutsch D

- Page 195 and 196:

Inhaltsverzeichnis Vorwort Beschrei

- Page 197 and 198:

Eingriffe 6 Wartung Anhang Inhaltsv

- Page 199 and 200:

Vorwort Zweck und Einschränkungen

- Page 201 and 202:

Beschreibung D

- Page 203 and 204:

1 Hauptteile 1.1 Zweckbestimmung MC

- Page 205 and 206:

1.3 Schnittstelle Aggregat-Werkzeug

- Page 207 and 208:

1.3.4 Sägeblatt- und Zangenfutter

- Page 209 and 210:

1.5 Konventionen MC S.r.l. © - 010

- Page 211 and 212:

2 Vorbereitung 2.1 Installation des

- Page 213 and 214:

2.2 Montage des Flanschs an der Ele

- Page 215 and 216:

Anwendung D

- Page 217 and 218:

MC S.r.l. © - 0103h00de.fm141207 3

- Page 219 and 220:

3.3 Schneidwerkzeuge 3.3.1 Flansch

- Page 221 and 222:

MC S.r.l. © - 0103h00de.fm141207 3

- Page 223 and 224:

MC S.r.l. © - 0104h00de.fm141207 4

- Page 225 and 226:

4.3 Schneidwerkzeuge 4.3.1 Flansch

- Page 227 and 228:

4.3.3 Befestigung mit 6 Schrauben T

- Page 229 and 230:

5 Einstellungen MC S.r.l. © - 0105

- Page 231 and 232:

MC S.r.l. © - 0105h00de.fm141207 5

- Page 233 and 234:

Eingriffe D

- Page 235 and 236:

6 Wartung 6 Wartung Während des Um

- Page 237 and 238:

6.3 Fettschmierung 6.3.1 Schmierpro

- Page 239 and 240:

6.4.1 Ölstandkontrolle Das Aggrega

- Page 241 and 242:

6 Wartung Ein Sammelbecken für das

- Page 243 and 244:

6.5 Reinigung A 6 Wartung Die angeg

- Page 245 and 246:

Anhang D

- Page 247 and 248:

A Informationen zur Sicherheit A.1

- Page 249 and 250:

� Eine Schutzbrille mit seitliche

- Page 251 and 252:

A.6 Pflichtenhinweise 6 Sicherstell

- Page 253 and 254:

Analytischer Index A Allgemeine Ver

- Page 255 and 256:

Español E

- Page 257 and 258:

Índice de los contenidos Premisa D

- Page 259 and 260:

Índice de los contenidos 6.5 Limpi

- Page 261 and 262:

Premisa Objeto y límites del manua

- Page 263 and 264:

Descripción E

- Page 265 and 266:

MC S.r.l. © - 0101h00e.fm141207 1

- Page 267 and 268:

1.3 Interfaz agregado-herramienta 1

- Page 269 and 270:

1.3.4 Conexión hoja y pinza MC S.r

- Page 271 and 272:

1.5 Convenciones MC S.r.l. © - 010

- Page 273 and 274:

2 Preparación 2.1 Instalación del

- Page 275 and 276:

MC S.r.l. © - 0102h00e.fm141207 2

- Page 277 and 278:

Uso E

- Page 279 and 280:

MC S.r.l. © - 0103h00e.fm141207 3

- Page 281 and 282:

3.3 Herramientas para corte 3.3.1 B

- Page 283 and 284:

MC S.r.l. © - 0103h00e.fm141207 3

- Page 285 and 286:

MC S.r.l. © - 0104h00e.fm141207 4

- Page 287 and 288:

4.3 Herramientas para corte 4.3.1 B

- Page 289 and 290:

4.3.3 Fijación de 6 tornillos Torx

- Page 291 and 292:

5 Regulaciones MC S.r.l. © - 0105h

- Page 293 and 294:

MC S.r.l. © - 0105h00e.fm141207 5

- Page 295 and 296:

Intervenciones E

- Page 297 and 298:

6 Mantenimiento 6 Mantenimiento Dur

- Page 299 and 300:

6.3 Lubricación con grasa 6.3.1 Pr

- Page 301 and 302:

6.4.1 Verificación del nivel de ac

- Page 303 and 304:

6 Mantenimiento Posicionarse en una

- Page 305 and 306:

6.5 Limpieza A 6 Mantenimiento Limp

- Page 307 and 308:

Apéndices E

- Page 309 and 310:

A Información sobre la seguridad A

- Page 311 and 312:

MC S.r.l. © - 01ah00e.fm141207 A I

- Page 313 and 314:

MC S.r.l. © - 01ah00e.fm141207 A I

- Page 315 and 316:

Índice analítico A aceite lubrica