Lichtenbergschule Darmstadt 18. - 21. Juli 2005

Lichtenbergschule Darmstadt 18. - 21. Juli 2005

Lichtenbergschule Darmstadt 18. - 21. Juli 2005

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

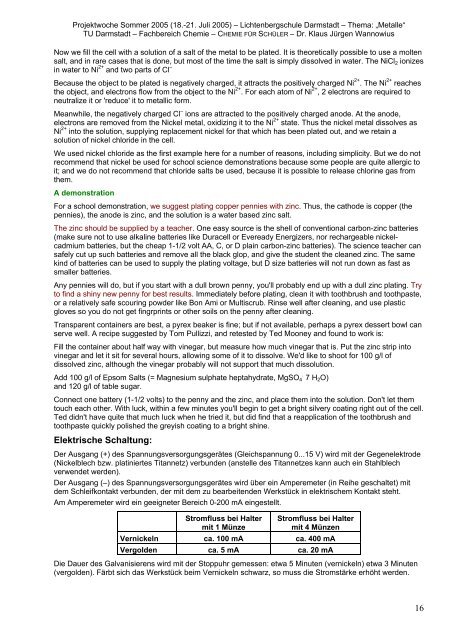

Projektwoche Sommer <strong>2005</strong> (<strong>18.</strong>-<strong>21.</strong> <strong>Juli</strong> <strong>2005</strong>) – <strong>Lichtenbergschule</strong> <strong>Darmstadt</strong> – Thema: „Metalle“TU <strong>Darmstadt</strong> – Fachbereich Chemie – CHEMIE FÜR SCHÜLER – Dr. Klaus Jürgen WannowiusNow we fill the cell with a solution of a salt of the metal to be plated. It is theoretically possible to use a moltensalt, and in rare cases that is done, but most of the time the salt is simply dissolved in water. The NiCl 2 ionizesin water to Ni 2+ and two parts of Cl –Because the object to be plated is negatively charged, it attracts the positively charged Ni 2+ . The Ni 2+ reachesthe object, and electrons flow from the object to the Ni 2+ . For each atom of Ni 2+ , 2 electrons are required toneutralize it or 'reduce' it to metallic form.Meanwhile, the negatively charged Cl – ions are attracted to the positively charged anode. At the anode,electrons are removed from the Nickel metal, oxidizing it to the Ni 2+ state. Thus the nickel metal dissolves asNi 2+ into the solution, supplying replacement nickel for that which has been plated out, and we retain asolution of nickel chloride in the cell.We used nickel chloride as the first example here for a number of reasons, including simplicity. But we do notrecommend that nickel be used for school science demonstrations because some people are quite allergic toit; and we do not recommend that chloride salts be used, because it is possible to release chlorine gas fromthem.A demonstrationFor a school demonstration, we suggest plating copper pennies with zinc. Thus, the cathode is copper (thepennies), the anode is zinc, and the solution is a water based zinc salt.The zinc should be supplied by a teacher. One easy source is the shell of conventional carbon-zinc batteries(make sure not to use alkaline batteries like Duracell or Eveready Energizers, nor rechargeable nickelcadmiumbatteries, but the cheap 1-1/2 volt AA, C, or D plain carbon-zinc batteries). The science teacher cansafely cut up such batteries and remove all the black glop, and give the student the cleaned zinc. The samekind of batteries can be used to supply the plating voltage, but D size batteries will not run down as fast assmaller batteries.Any pennies will do, but if you start with a dull brown penny, you'll probably end up with a dull zinc plating. Tryto find a shiny new penny for best results. Immediately before plating, clean it with toothbrush and toothpaste,or a relatively safe scouring powder like Bon Ami or Multiscrub. Rinse well after cleaning, and use plasticgloves so you do not get fingrprints or other soils on the penny after cleaning.Transparent containers are best, a pyrex beaker is fine; but if not available, perhaps a pyrex dessert bowl canserve well. A recipe suggested by Tom Pullizzi, and retested by Ted Mooney and found to work is:Fill the container about half way with vinegar, but measure how much vinegar that is. Put the zinc strip intovinegar and let it sit for several hours, allowing some of it to dissolve. We'd like to shoot for 100 g/l ofdissolved zinc, although the vinegar probably will not support that much dissolution.Add 100 g/l of Epsom Salts (= Magnesium sulphate heptahydrate, MgSO 4 . 7 H 2 O)and 120 g/l of table sugar.Connect one battery (1-1/2 volts) to the penny and the zinc, and place them into the solution. Don't let themtouch each other. With luck, within a few minutes you'll begin to get a bright silvery coating right out of the cell.Ted didn't have quite that much luck when he tried it, but did find that a reapplication of the toothbrush andtoothpaste quickly polished the greyish coating to a bright shine.Elektrische Schaltung:Der Ausgang (+) des Spannungsversorgungsgerätes (Gleichspannung 0...15 V) wird mit der Gegenelektrode(Nickelblech bzw. platiniertes Titannetz) verbunden (anstelle des Titannetzes kann auch ein Stahlblechverwendet werden).Der Ausgang (–) des Spannungsversorgungsgerätes wird über ein Amperemeter (in Reihe geschaltet) mitdem Schleifkontakt verbunden, der mit dem zu bearbeitenden Werkstück in elektrischem Kontakt steht.Am Amperemeter wird ein geeigneter Bereich 0-200 mA eingestellt.Stromfluss bei Haltermit 1 MünzeStromfluss bei Haltermit 4 MünzenVernickeln ca. 100 mA ca. 400 mAVergolden ca. 5 mA ca. 20 mADie Dauer des Galvanisierens wird mit der Stoppuhr gemessen: etwa 5 Minuten (vernickeln) etwa 3 Minuten(vergolden). Färbt sich das Werkstück beim Vernickeln schwarz, so muss die Stromstärke erhöht werden.16