Die Sonderausgabe der MTZ hier herunterladen (6 MB - MS Motor ...

Die Sonderausgabe der MTZ hier herunterladen (6 MB - MS Motor ...

Die Sonderausgabe der MTZ hier herunterladen (6 MB - MS Motor ...

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

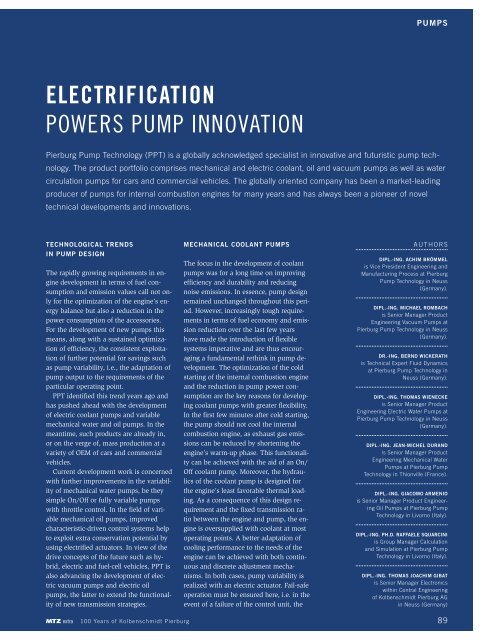

ELECTRIFICATION<br />

POWERS PUMP INNOVATION<br />

Pierburg Pump Technology (PPT) is a globally acknowledged specialist in innovative and futuristic pump technology.<br />

The product portfolio comprises mechanical and electric coolant, oil and vacuum pumps as well as water<br />

circulation pumps for cars and commercial vehicles. The globally oriented company has been a market-leading<br />

producer of pumps for internal combustion engines for many years and has always been a pioneer of novel<br />

technical developments and innovations.<br />

TECHNOLOGICAL TRENDS<br />

IN PUMP DESIGN<br />

The rapidly growing requirements in engine<br />

development in terms of fuel consumption<br />

and emission values call not only<br />

for the optimization of the engine’s energy<br />

balance but also a reduction in the<br />

power consumption of the accessories.<br />

For the development of new pumps this<br />

means, along with a sustained optimization<br />

of efficiency, the consistent exploitation<br />

of further potential for savings such<br />

as pump variability, i.e., the adaptation of<br />

pump output to the requirements of the<br />

particular operating point.<br />

PPT identified this trend years ago and<br />

has pushed ahead with the development<br />

of electric coolant pumps and variable<br />

mechanical water and oil pumps. In the<br />

meantime, such products are already in,<br />

or on the verge of, mass production at a<br />

variety of OEM of cars and commercial<br />

vehicles.<br />

Current development work is concerned<br />

with further improvements in the variability<br />

of mechanical water pumps, be they<br />

simple On/Off or fully variable pumps<br />

with throttle control. In the field of variable<br />

mechanical oil pumps, improved<br />

characteristic-driven control systems help<br />

to exploit extra conservation potential by<br />

using electrified actuators. In view of the<br />

drive concepts of the future such as hybrid,<br />

electric and fuel-cell vehicles, PPT is<br />

also advancing the development of electric<br />

vacuum pumps and electric oil<br />

pumps, the latter to extend the functionality<br />

of new transmission strategies.<br />

100 Years of Kolbenschmidt Pierburg<br />

MECHANICAL COOLANT PUMPS<br />

The focus in the development of coolant<br />

pumps was for a long time on improving<br />

efficiency and durability and reducing<br />

noise emissions. In essence, pump design<br />

remained unchanged throughout this period.<br />

However, increasingly tough requirements<br />

in terms of fuel economy and emission<br />

reduction over the last few years<br />

have made the introduction of flexible<br />

systems imperative and are thus encouraging<br />

a fundamental rethink in pump development.<br />

The optimization of the cold<br />

starting of the internal combustion engine<br />

and the reduction in pump power consumption<br />

are the key reasons for developing<br />

coolant pumps with greater flexibility.<br />

In the first few minutes after cold starting,<br />

the pump should not cool the internal<br />

combustion engine, as exhaust gas emissions<br />

can be reduced by shortening the<br />

engine’s warm-up phase. This functionality<br />

can be achieved with the aid of an On/<br />

Off coolant pump. Moreover, the hydraulics<br />

of the coolant pump is designed for<br />

the engine’s least favorable thermal loading.<br />

As a consequence of this design requirement<br />

and the fixed transmission ratio<br />

between the engine and pump, the engine<br />

is oversupplied with coolant at most<br />

operating points. A better adaptation of<br />

cooling performance to the needs of the<br />

engine can be achieved with both continuous<br />

and discrete adjustment mechanisms.<br />

In both cases, pump variability is<br />

realized with an electric actuator. Fail-safe<br />

operation must be ensured here, i.e. in the<br />

event of a failure of the control unit, the<br />

PUMPS<br />

AUTHORS<br />

DIPL.-ING. ACHIM BRÖMMEL<br />

is Vice President Engineering and<br />

Manufacturing Process at Pierburg<br />

Pump Technology in Neuss<br />

(Germany).<br />

DIPL.-ING. MICHAEL RO<strong>MB</strong>ACH<br />

is Senior Manager Product<br />

Engineering Vacuum Pumps at<br />

Pierburg Pump Technology in Neuss<br />

(Germany).<br />

DR.-ING. BERND WICKERATH<br />

is Technical Expert Fluid Dynamics<br />

at Pierburg Pump Technology in<br />

Neuss (Germany).<br />

DIPL.-ING. THOMAS WIENECKE<br />

is Senior Manager Product<br />

Engineering Electric Water Pumps at<br />

Pierburg Pump Technology in Neuss<br />

(Germany).<br />

DIPL.-ING. JEAN-MICHEL DURAND<br />

is Senior Manager Product<br />

Engineering Mechanical Water<br />

Pumps at Pierburg Pump<br />

Technology in Thionville (France).<br />

DIPL.-ING. GIACOMO ARMENIO<br />

is Senior Manager Product Engineering<br />

Oil Pumps at Pierburg Pump<br />

Technology in Livorno (Italy).<br />

DIPL.-ING. PH.D. RAFFAELE SQUARCINI<br />

is Group Manager Calculation<br />

and Simulation at Pierburg Pump<br />

Technology in Livorno (Italy).<br />

DIPL.-ING. THOMAS JOACHIM GIBAT<br />

is Senior Manager Electronics<br />

within Central Engineering<br />

of Kolbenschmidt Pierburg AG<br />

in Neuss (Germany)<br />

89