2 What is an fault arc - Die BG ETEM

2 What is an fault arc - Die BG ETEM

2 What is an fault arc - Die BG ETEM

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5 St<strong>an</strong>dardized test procedures for PPE products against thermal <strong>arc</strong> hazards<br />

5.2 Arc rating test IEC 61482-1-1<br />

How the test works<br />

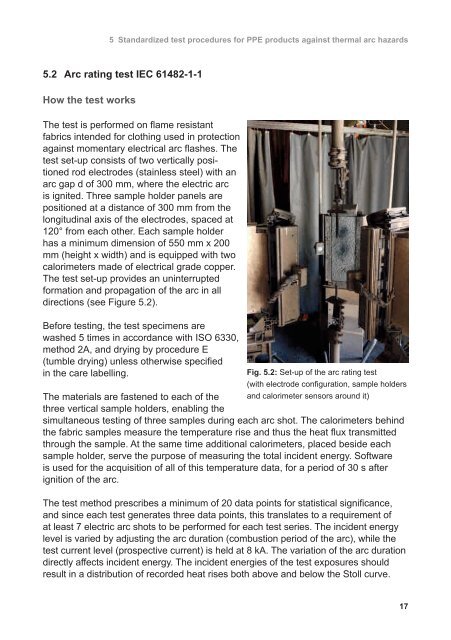

The test <strong>is</strong> performed on flame res<strong>is</strong>t<strong>an</strong>t<br />

fabrics intended for clothing used in protection<br />

against momentary electrical <strong>arc</strong> flashes. The<br />

test set-up cons<strong>is</strong>ts of two vertically positioned<br />

rod electrodes (stainless steel) with <strong>an</strong><br />

<strong>arc</strong> gap d of 300 mm, where the electric <strong>arc</strong><br />

<strong>is</strong> ignited. Three sample holder p<strong>an</strong>els are<br />

positioned at a d<strong>is</strong>t<strong>an</strong>ce of 300 mm from the<br />

longitudinal ax<strong>is</strong> of the electrodes, spaced at<br />

120° from each other. Each sample holder<br />

has a minimum dimension of 550 mm x 200<br />

mm (height x width) <strong>an</strong>d <strong>is</strong> equipped with two<br />

calorimeters made of electrical grade copper.<br />

The test set-up provides <strong>an</strong> uninterrupted<br />

formation <strong>an</strong>d propagation of the <strong>arc</strong> in all<br />

directions (see Figure 5.2).<br />

Before testing, the test specimens are<br />

washed 5 times in accord<strong>an</strong>ce with ISO 6330,<br />

method 2A, <strong>an</strong>d drying by procedure E<br />

(tumble drying) unless otherw<strong>is</strong>e specified<br />

in the care labelling.<br />

Fig. 5.2: Set-up of the <strong>arc</strong> rating test<br />

(with electrode configuration, sample holders<br />

The materials are fastened to each of the <strong>an</strong>d calorimeter sensors around it)<br />

three vertical sample holders, enabling the<br />

simult<strong>an</strong>eous testing of three samples during each <strong>arc</strong> shot. The calorimeters behind<br />

the fabric samples measure the temperature r<strong>is</strong>e <strong>an</strong>d thus the heat flux tr<strong>an</strong>smitted<br />

through the sample. At the same time additional calorimeters, placed beside each<br />

sample holder, serve the purpose of measuring the total incident energy. Software<br />

<strong>is</strong> used for the acqu<strong>is</strong>ition of all of th<strong>is</strong> temperature data, for a period of 30 s after<br />

ignition of the <strong>arc</strong>.<br />

The test method prescribes a minimum of 20 data points for stat<strong>is</strong>tical signific<strong>an</strong>ce,<br />

<strong>an</strong>d since each test generates three data points, th<strong>is</strong> tr<strong>an</strong>slates to a requirement of<br />

at least 7 electric <strong>arc</strong> shots to be performed for each test series. The incident energy<br />

level <strong>is</strong> varied by adjusting the <strong>arc</strong> duration (combustion period of the <strong>arc</strong>), while the<br />

test current level (prospective current) <strong>is</strong> held at 8 kA. The variation of the <strong>arc</strong> duration<br />

directly affects incident energy. The incident energies of the test exposures should<br />

result in a d<strong>is</strong>tribution of recorded heat r<strong>is</strong>es both above <strong>an</strong>d below the Stoll curve.<br />

17