2 What is an fault arc - Die BG ETEM

2 What is an fault arc - Die BG ETEM

2 What is an fault arc - Die BG ETEM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

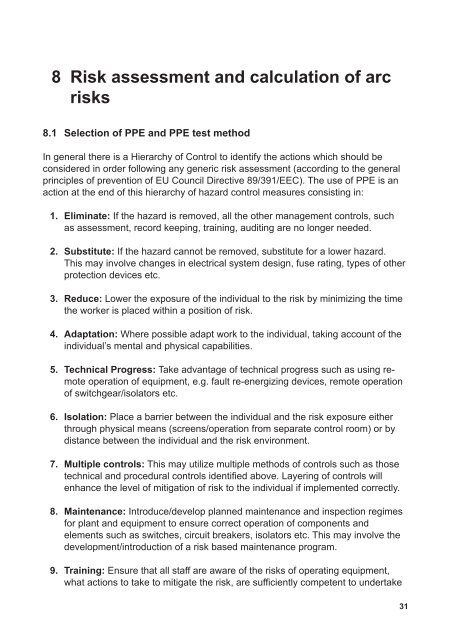

8 R<strong>is</strong>k assessment <strong>an</strong>d calculation of <strong>arc</strong><br />

r<strong>is</strong>ks<br />

8.1 Selection of PPE <strong>an</strong>d PPE test method<br />

In general there <strong>is</strong> a Hier<strong>arc</strong>hy of Control to identify the actions which should be<br />

considered in order following <strong>an</strong>y generic r<strong>is</strong>k assessment (according to the general<br />

principles of prevention of EU Council Directive 89/391/EEC). The use of PPE <strong>is</strong> <strong>an</strong><br />

action at the end of th<strong>is</strong> hier<strong>arc</strong>hy of hazard control measures cons<strong>is</strong>ting in:<br />

1. Eliminate: If the hazard <strong>is</strong> removed, all the other m<strong>an</strong>agement controls, such<br />

as assessment, record keeping, training, auditing are no longer needed.<br />

2. Substitute: If the hazard c<strong>an</strong>not be removed, substitute for a lower hazard.<br />

Th<strong>is</strong> may involve ch<strong>an</strong>ges in electrical system design, fuse rating, types of other<br />

protection devices etc.<br />

3. Reduce: Lower the exposure of the individual to the r<strong>is</strong>k by minimizing the time<br />

the worker <strong>is</strong> placed within a position of r<strong>is</strong>k.<br />

4. Adaptation: Where possible adapt work to the individual, taking account of the<br />

individual’s mental <strong>an</strong>d physical capabilities.<br />

5. Technical Progress: Take adv<strong>an</strong>tage of technical progress such as using remote<br />

operation of equipment, e.g. <strong>fault</strong> re-energizing devices, remote operation<br />

of switchgear/<strong>is</strong>olators etc.<br />

6. Isolation: Place a barrier between the individual <strong>an</strong>d the r<strong>is</strong>k exposure either<br />

through physical me<strong>an</strong>s (screens/operation from separate control room) or by<br />

d<strong>is</strong>t<strong>an</strong>ce between the individual <strong>an</strong>d the r<strong>is</strong>k environment.<br />

7. Multiple controls: Th<strong>is</strong> may utilize multiple methods of controls such as those<br />

technical <strong>an</strong>d procedural controls identified above. Layering of controls will<br />

enh<strong>an</strong>ce the level of mitigation of r<strong>is</strong>k to the individual if implemented correctly.<br />

8. Mainten<strong>an</strong>ce: Introduce/develop pl<strong>an</strong>ned mainten<strong>an</strong>ce <strong>an</strong>d inspection regimes<br />

for pl<strong>an</strong>t <strong>an</strong>d equipment to ensure correct operation of components <strong>an</strong>d<br />

elements such as switches, circuit breakers, <strong>is</strong>olators etc. Th<strong>is</strong> may involve the<br />

development/introduction of a r<strong>is</strong>k based mainten<strong>an</strong>ce program.<br />

9. Training: Ensure that all staff are aware of the r<strong>is</strong>ks of operating equipment,<br />

what actions to take to mitigate the r<strong>is</strong>k, are sufficiently competent to undertake<br />

31