2012 - Europe Direct Iasi

2012 - Europe Direct Iasi

2012 - Europe Direct Iasi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EUROINVENT <strong>2012</strong><br />

CLASS 1.<br />

Environment - Pollution Control<br />

1.1.<br />

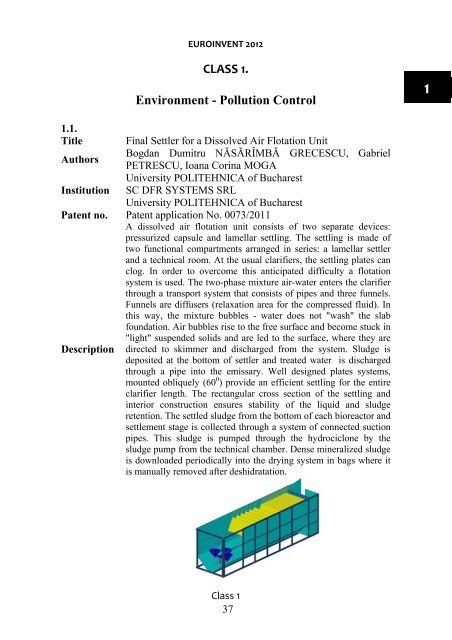

Title Final Settler for a Dissolved Air Flotation Unit<br />

Bogdan Dumitru NĂSĂRÎMBĂ GRECESCU, Gabriel<br />

Authors<br />

PETRESCU, Ioana Corina MOGA<br />

University POLITEHNICA of Bucharest<br />

Institution SC DFR SYSTEMS SRL<br />

University POLITEHNICA of Bucharest<br />

Patent no. Patent application No. 0073/2011<br />

A dissolved air flotation unit consists of two separate devices:<br />

pressurized capsule and lamellar settling. The settling is made of<br />

two functional compartments arranged in series: a lamellar settler<br />

and a technical room. At the usual clarifiers, the settling plates can<br />

clog. In order to overcome this anticipated difficulty a flotation<br />

system is used. The two-phase mixture air-water enters the clarifier<br />

through a transport system that consists of pipes and three funnels.<br />

Funnels are diffusers (relaxation area for the compressed fluid). In<br />

this way, the mixture bubbles - water does not "wash" the slab<br />

foundation. Air bubbles rise to the free surface and become stuck in<br />

"light" suspended solids and are led to the surface, where they are<br />

Description directed to skimmer and discharged from the system. Sludge is<br />

deposited at the bottom of settler and treated water is discharged<br />

through a pipe into the emissary. Well designed plates systems,<br />

mounted obliquely (60 0 ) provide an efficient settling for the entire<br />

clarifier length. The rectangular cross section of the settling and<br />

interior construction ensures stability of the liquid and sludge<br />

retention. The settled sludge from the bottom of each bioreactor and<br />

settlement stage is collected through a system of connected suction<br />

pipes. This sludge is pumped through the hydrociclone by the<br />

sludge pump from the technical chamber. Dense mineralized sludge<br />

is downloaded periodically into the drying system in bags where it<br />

is manually removed after deshidratation.<br />

Class 1<br />

37<br />

1