Advanced Welding Processes: Technologies and Process Control

Advanced Welding Processes: Technologies and Process Control

Advanced Welding Processes: Technologies and Process Control

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

282<br />

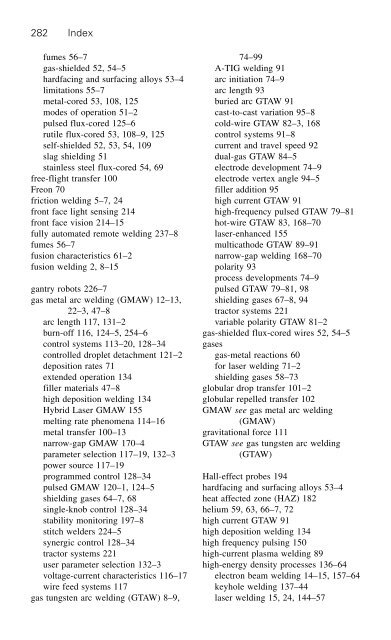

Index<br />

fumes 56–7<br />

gas-shielded 52, 54–5<br />

hardfacing <strong>and</strong> surfacing alloys 53–4<br />

limitations 55–7<br />

metal-cored 53, 108, 125<br />

modes of operation 51–2<br />

pulsed flux-cored 125–6<br />

rutile flux-cored 53, 108–9, 125<br />

self-shielded 52, 53, 54, 109<br />

slag shielding 51<br />

stainless steel flux-cored 54, 69<br />

free-flight transfer 100<br />

Freon 70<br />

friction welding 5–7, 24<br />

front face light sensing 214<br />

front face vision 214–15<br />

fully automated remote welding 237–8<br />

fumes 56–7<br />

fusion characteristics 61–2<br />

fusion welding 2, 8–15<br />

gantry robots 226–7<br />

gas metal arc welding (GMAW) 12–13,<br />

22–3, 47–8<br />

arc length 117, 131–2<br />

burn-off 116, 124–5, 254–6<br />

control systems 113–20, 128–34<br />

controlled droplet detachment 121–2<br />

deposition rates 71<br />

extended operation 134<br />

filler materials 47–8<br />

high deposition welding 134<br />

Hybrid Laser GMAW 155<br />

melting rate phenomena 114–16<br />

metal transfer 100–13<br />

narrow-gap GMAW 170–4<br />

parameter selection 117–19, 132–3<br />

power source 117–19<br />

programmed control 128–34<br />

pulsed GMAW 120–1, 124–5<br />

shielding gases 64–7, 68<br />

single-knob control 128–34<br />

stability monitoring 197–8<br />

stitch welders 224–5<br />

synergic control 128–34<br />

tractor systems 221<br />

user parameter selection 132–3<br />

voltage-current characteristics 116–17<br />

wire feed systems 117<br />

gas tungsten arc welding (GTAW) 8–9,<br />

74–99<br />

A-TIG welding 91<br />

arc initiation 74–9<br />

arc length 93<br />

buried arc GTAW 91<br />

cast-to-cast variation 95–8<br />

cold-wire GTAW 82–3, 168<br />

control systems 91–8<br />

current <strong>and</strong> travel speed 92<br />

dual-gas GTAW 84–5<br />

electrode development 74–9<br />

electrode vertex angle 94–5<br />

filler addition 95<br />

high current GTAW 91<br />

high-frequency pulsed GTAW 79–81<br />

hot-wire GTAW 83, 168–70<br />

laser-enhanced 155<br />

multicathode GTAW 89–91<br />

narrow-gap welding 168–70<br />

polarity 93<br />

process developments 74–9<br />

pulsed GTAW 79–81, 98<br />

shielding gases 67–8, 94<br />

tractor systems 221<br />

variable polarity GTAW 81–2<br />

gas-shielded flux-cored wires 52, 54–5<br />

gases<br />

gas-metal reactions 60<br />

for laser welding 71–2<br />

shielding gases 58–73<br />

globular drop transfer 101–2<br />

globular repelled transfer 102<br />

GMAW see gas metal arc welding<br />

(GMAW)<br />

gravitational force 111<br />

GTAW see gas tungsten arc welding<br />

(GTAW)<br />

Hall-effect probes 194<br />

hardfacing <strong>and</strong> surfacing alloys 53–4<br />

heat affected zone (HAZ) 182<br />

helium 59, 63, 66–7, 72<br />

high current GTAW 91<br />

high deposition welding 134<br />

high frequency pulsing 150<br />

high-current plasma welding 89<br />

high-energy density processes 136–64<br />

electron beam welding 14–15, 157–64<br />

keyhole welding 137–44<br />

laser welding 15, 24, 144–57