flow and level measurement - Omega Engineering

flow and level measurement - Omega Engineering

flow and level measurement - Omega Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

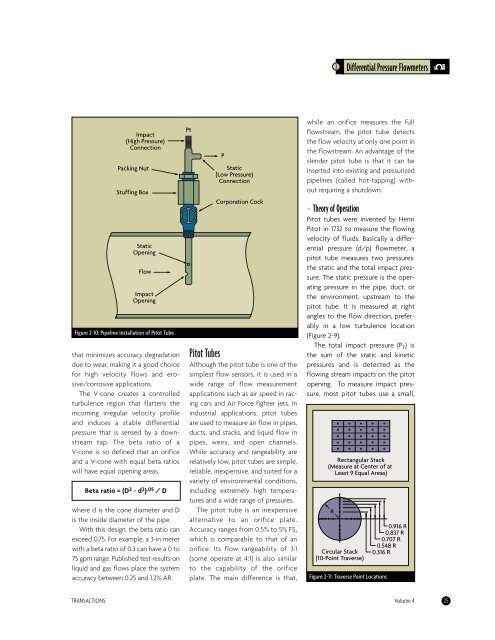

Impact<br />

(High Pressure)<br />

Connection<br />

Packing Nut<br />

Stuffing Box<br />

Static<br />

Opening<br />

Flow<br />

Impact<br />

Opening<br />

Figure 2-10: Pipeline Installation of Pitot Tube<br />

that minimizes accuracy degradation<br />

due to wear, making it a good choice<br />

for high velocity <strong>flow</strong>s <strong>and</strong> erosive/corrosive<br />

applications.<br />

The V-cone creates a controlled<br />

turbulence region that flattens the<br />

incoming irregular velocity profile<br />

<strong>and</strong> induces a stable differential<br />

pressure that is sensed by a downstream<br />

tap. The beta ratio of a<br />

V-cone is so defined that an orifice<br />

<strong>and</strong> a V-cone with equal beta ratios<br />

will have equal opening areas.<br />

Beta ratio = (D 2 - d 2 ) .05 / D<br />

where d is the cone diameter <strong>and</strong> D<br />

is the inside diameter of the pipe.<br />

With this design, the beta ratio can<br />

exceed 0.75. For example, a 3-in meter<br />

with a beta ratio of 0.3 can have a 0 to<br />

75 gpm range. Published test results on<br />

liquid <strong>and</strong> gas <strong>flow</strong>s place the system<br />

accuracy between 0.25 <strong>and</strong> 1.2% AR.<br />

Pt<br />

P<br />

Static<br />

(Low Pressure)<br />

Connection<br />

Corporation Cock<br />

Pitot Tubes<br />

Although the pitot tube is one of the<br />

simplest <strong>flow</strong> sensors, it is used in a<br />

wide range of <strong>flow</strong> <strong>measurement</strong><br />

applications such as air speed in racing<br />

cars <strong>and</strong> Air Force fighter jets. In<br />

industrial applications, pitot tubes<br />

are used to measure air <strong>flow</strong> in pipes,<br />

ducts, <strong>and</strong> stacks, <strong>and</strong> liquid <strong>flow</strong> in<br />

pipes, weirs, <strong>and</strong> open channels.<br />

While accuracy <strong>and</strong> rangeability are<br />

relatively low, pitot tubes are simple,<br />

reliable, inexpensive, <strong>and</strong> suited for a<br />

variety of environmental conditions,<br />

including extremely high temperatures<br />

<strong>and</strong> a wide range of pressures.<br />

The pitot tube is an inexpensive<br />

alternative to an orifice plate.<br />

Accuracy ranges from 0.5% to 5% FS,<br />

which is comparable to that of an<br />

orifice. Its <strong>flow</strong> rangeability of 3:1<br />

(some operate at 4:1) is also similar<br />

to the capability of the orifice<br />

plate. The main difference is that,<br />

2 Differential Pressure Flowmeters<br />

while an orifice measures the full<br />

<strong>flow</strong>stream, the pitot tube detects<br />

the <strong>flow</strong> velocity at only one point in<br />

the <strong>flow</strong>stream. An advantage of the<br />

slender pitot tube is that it can be<br />

inserted into existing <strong>and</strong> pressurized<br />

pipelines (called hot-tapping) without<br />

requiring a shutdown.<br />

• Theory of Operation<br />

Pitot tubes were invented by Henri<br />

Pitot in 1732 to measure the <strong>flow</strong>ing<br />

velocity of fluids. Basically a differential<br />

pressure (d/p) <strong>flow</strong>meter, a<br />

pitot tube measures two pressures:<br />

the static <strong>and</strong> the total impact pressure.<br />

The static pressure is the operating<br />

pressure in the pipe, duct, or<br />

the environment, upstream to the<br />

pitot tube. It is measured at right<br />

angles to the <strong>flow</strong> direction, preferably<br />

in a low turbulence location<br />

(Figure 2-9).<br />

The total impact pressure (P T ) is<br />

the sum of the static <strong>and</strong> kinetic<br />

pressures <strong>and</strong> is detected as the<br />

<strong>flow</strong>ing stream impacts on the pitot<br />

opening. To measure impact pressure,<br />

most pitot tubes use a small,<br />

Rectangular Stack<br />

(Measure at Center of at<br />

Least 9 Equal Areas)<br />

Circular Stack<br />

(10-Point Traverse)<br />

Figure 2-11: Traverse Point Locations<br />

0.916 R<br />

0.837 R<br />

0.707 R<br />

0.548 R<br />

0.316 R<br />

TRANSACTIONS Volume 4 25<br />

R