flow and level measurement - Omega Engineering

flow and level measurement - Omega Engineering

flow and level measurement - Omega Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Because they are very sensitive to the<br />

velocity profile of the <strong>flow</strong>ing stream,<br />

they must be profiled at several<br />

points across the <strong>flow</strong> path.<br />

Insertion turbine meters can be<br />

designed for gas applications (small,<br />

lightweight rotor) or for liquid (larger<br />

rotor, water-lubricated bearings).<br />

They are often used in large diameter<br />

pipelines where it would be costprohibitive<br />

to install a full size meter.<br />

They can be hot-tapped into existing<br />

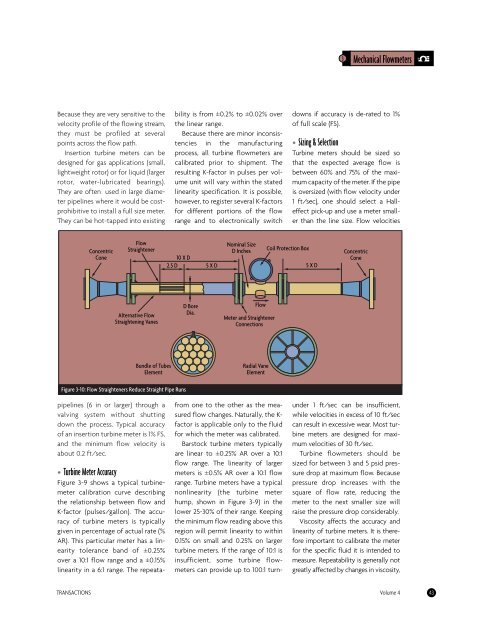

Concentric<br />

Cone<br />

Flow<br />

Straightener<br />

Alternative Flow<br />

Straightening Vanes<br />

Bundle of Tubes<br />

Element<br />

Figure 3-10: Flow Straighteners Reduce Straight Pipe Runs<br />

pipelines (6 in or larger) through a<br />

valving system without shutting<br />

down the process. Typical accuracy<br />

of an insertion turbine meter is 1% FS,<br />

<strong>and</strong> the minimum <strong>flow</strong> velocity is<br />

about 0.2 ft/sec.<br />

• Turbine Meter Accuracy<br />

Figure 3-9 shows a typical turbinemeter<br />

calibration curve describing<br />

the relationship between <strong>flow</strong> <strong>and</strong><br />

K-factor (pulses/gallon). The accuracy<br />

of turbine meters is typically<br />

given in percentage of actual rate (%<br />

AR). This particular meter has a linearity<br />

tolerance b<strong>and</strong> of ±0.25%<br />

over a 10:1 <strong>flow</strong> range <strong>and</strong> a ±0.15%<br />

linearity in a 6:1 range. The repeata-<br />

bility is from ±0.2% to ±0.02% over<br />

the linear range.<br />

Because there are minor inconsistencies<br />

in the manufacturing<br />

process, all turbine <strong>flow</strong>meters are<br />

calibrated prior to shipment. The<br />

resulting K-factor in pulses per volume<br />

unit will vary within the stated<br />

linearity specification. It is possible,<br />

however, to register several K-factors<br />

for different portions of the <strong>flow</strong><br />

range <strong>and</strong> to electronically switch<br />

10 X D<br />

2.5 D 5 X D<br />

D Bore<br />

Dia.<br />

Nominal Size<br />

D Inches<br />

from one to the other as the measured<br />

<strong>flow</strong> changes. Naturally, the Kfactor<br />

is applicable only to the fluid<br />

for which the meter was calibrated.<br />

Barstock turbine meters typically<br />

are linear to ±0.25% AR over a 10:1<br />

<strong>flow</strong> range. The linearity of larger<br />

meters is ±0.5% AR over a 10:1 <strong>flow</strong><br />

range. Turbine meters have a typical<br />

nonlinearity (the turbine meter<br />

hump, shown in Figure 3-9) in the<br />

lower 25-30% of their range. Keeping<br />

the minimum <strong>flow</strong> reading above this<br />

region will permit linearity to within<br />

0.15% on small <strong>and</strong> 0.25% on larger<br />

turbine meters. If the range of 10:1 is<br />

insufficient, some turbine <strong>flow</strong>meters<br />

can provide up to 100:1 turn-<br />

Coil Protection Box<br />

3 Mechanical Flowmeters<br />

downs if accuracy is de-rated to 1%<br />

of full scale (FS).<br />

• Sizing & Selection<br />

Turbine meters should be sized so<br />

that the expected average <strong>flow</strong> is<br />

between 60% <strong>and</strong> 75% of the maximum<br />

capacity of the meter. If the pipe<br />

is oversized (with <strong>flow</strong> velocity under<br />

1 ft/sec), one should select a Halleffect<br />

pick-up <strong>and</strong> use a meter smaller<br />

than the line size. Flow velocities<br />

Concentric<br />

Cone<br />

under 1 ft/sec can be insufficient,<br />

while velocities in excess of 10 ft/sec<br />

can result in excessive wear. Most turbine<br />

meters are designed for maximum<br />

velocities of 30 ft/sec.<br />

Turbine <strong>flow</strong>meters should be<br />

sized for between 3 <strong>and</strong> 5 psid pressure<br />

drop at maximum <strong>flow</strong>. Because<br />

pressure drop increases with the<br />

square of <strong>flow</strong> rate, reducing the<br />

meter to the next smaller size will<br />

raise the pressure drop considerably.<br />

Viscosity affects the accuracy <strong>and</strong><br />

linearity of turbine meters. It is therefore<br />

important to calibrate the meter<br />

for the specific fluid it is intended to<br />

measure. Repeatability is generally not<br />

greatly affected by changes in viscosity,<br />

TRANSACTIONS Volume 4 43<br />

Flow<br />

Meter <strong>and</strong> Straightener<br />

Connections<br />

Radial Vane<br />

Element<br />

5 X D