flow and level measurement - Omega Engineering

flow and level measurement - Omega Engineering

flow and level measurement - Omega Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

increases. The higher the viscosity,<br />

the less slippage <strong>and</strong> the lower the<br />

measurable <strong>flow</strong> rate becomes. As<br />

viscosity decreases, the low <strong>flow</strong><br />

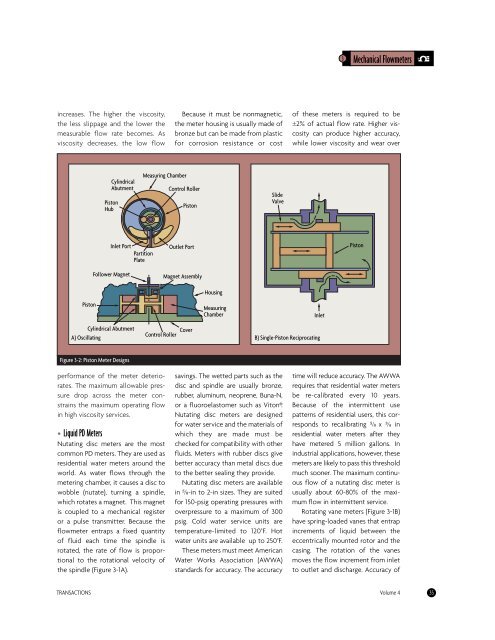

Piston<br />

Cylindrical<br />

Abutment<br />

Piston<br />

Hub<br />

Figure 3-2: Piston Meter Designs<br />

Inlet Port<br />

Partition<br />

Plate<br />

Follower Magnet<br />

Cylindrical Abutment<br />

A) Oscillating<br />

Measuring Chamber<br />

performance of the meter deteriorates.<br />

The maximum allowable pressure<br />

drop across the meter constrains<br />

the maximum operating <strong>flow</strong><br />

in high viscosity services.<br />

• Liquid PD Meters<br />

Nutating disc meters are the most<br />

common PD meters. They are used as<br />

residential water meters around the<br />

world. As water <strong>flow</strong>s through the<br />

metering chamber, it causes a disc to<br />

wobble (nutate), turning a spindle,<br />

which rotates a magnet. This magnet<br />

is coupled to a mechanical register<br />

or a pulse transmitter. Because the<br />

<strong>flow</strong>meter entraps a fixed quantity<br />

of fluid each time the spindle is<br />

rotated, the rate of <strong>flow</strong> is proportional<br />

to the rotational velocity of<br />

the spindle (Figure 3-1A).<br />

Because it must be nonmagnetic,<br />

the meter housing is usually made of<br />

bronze but can be made from plastic<br />

for corrosion resistance or cost<br />

Control Roller<br />

Piston<br />

Outlet Port<br />

Magnet Assembly<br />

Cover<br />

Control Roller<br />

Housing<br />

Measuring<br />

Chamber<br />

savings. The wetted parts such as the<br />

disc <strong>and</strong> spindle are usually bronze,<br />

rubber, aluminum, neoprene, Buna-N,<br />

or a fluoroelastomer such as Viton®.<br />

Nutating disc meters are designed<br />

for water service <strong>and</strong> the materials of<br />

which they are made must be<br />

checked for compatibility with other<br />

fluids. Meters with rubber discs give<br />

better accuracy than metal discs due<br />

to the better sealing they provide.<br />

Nutating disc meters are available<br />

in L-in to 2-in sizes. They are suited<br />

for 150-psig operating pressures with<br />

overpressure to a maximum of 300<br />

psig. Cold water service units are<br />

temperature-limited to 120°F. Hot<br />

water units are available up to 250°F.<br />

These meters must meet American<br />

Water Works Association (AWWA)<br />

st<strong>and</strong>ards for accuracy. The accuracy<br />

B) Single-Piston Reciprocating<br />

3 Mechanical Flowmeters<br />

of these meters is required to be<br />

±2% of actual <strong>flow</strong> rate. Higher viscosity<br />

can produce higher accuracy,<br />

while lower viscosity <strong>and</strong> wear over<br />

time will reduce accuracy. The AWWA<br />

requires that residential water meters<br />

be re-calibrated every 10 years.<br />

Because of the intermittent use<br />

patterns of residential users, this corresponds<br />

to recalibrating L x I in<br />

residential water meters after they<br />

have metered 5 million gallons. In<br />

industrial applications, however, these<br />

meters are likely to pass this threshold<br />

much sooner. The maximum continuous<br />

<strong>flow</strong> of a nutating disc meter is<br />

usually about 60-80% of the maximum<br />

<strong>flow</strong> in intermittent service.<br />

Rotating vane meters (Figure 3-1B)<br />

have spring-loaded vanes that entrap<br />

increments of liquid between the<br />

eccentrically mounted rotor <strong>and</strong> the<br />

casing. The rotation of the vanes<br />

moves the <strong>flow</strong> increment from inlet<br />

to outlet <strong>and</strong> discharge. Accuracy of<br />

TRANSACTIONS Volume 4 35<br />

Slide<br />

Valve<br />

Inlet<br />

Piston