Fluid mechanics of fibre suspensions related to papermaking - DiVA

Fluid mechanics of fibre suspensions related to papermaking - DiVA

Fluid mechanics of fibre suspensions related to papermaking - DiVA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

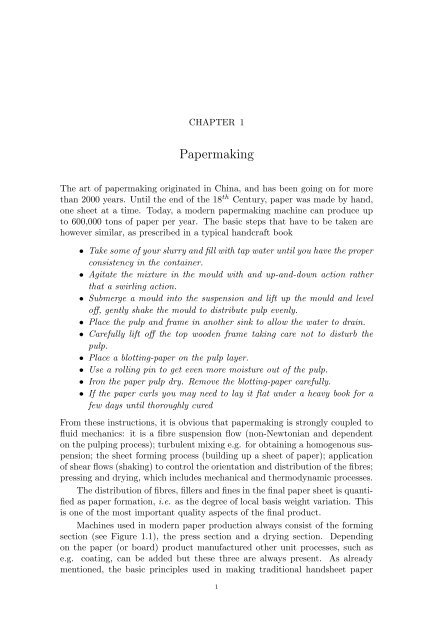

CHAPTER 1<br />

Papermaking<br />

The art <strong>of</strong> <strong>papermaking</strong> originated in China, and has been going on for more<br />

than 2000 years. Until the end <strong>of</strong> the 18 th Century, paper was made by hand,<br />

one sheet at a time. Today, a modern <strong>papermaking</strong> machine can produce up<br />

<strong>to</strong> 600,000 <strong>to</strong>ns <strong>of</strong> paper per year. The basic steps that have <strong>to</strong> be taken are<br />

however similar, as prescribed in a typical handcraft book<br />

• Take some <strong>of</strong> your slurry and fill with tap water until you have the proper<br />

consistency in the container.<br />

• Agitate the mixture in the mould with and up-and-down action rather<br />

that a swirling action.<br />

• Submerge a mould in<strong>to</strong> the suspension and lift up the mould and level<br />

<strong>of</strong>f, gently shake the mould <strong>to</strong> distribute pulp evenly.<br />

• Place the pulp and frame in another sink <strong>to</strong> allow the water <strong>to</strong> drain.<br />

• Carefully lift <strong>of</strong>f the <strong>to</strong>p wooden frame taking care not <strong>to</strong> disturb the<br />

pulp.<br />

• Place a blotting-paper on the pulp layer.<br />

• Use a rolling pin <strong>to</strong> get even more moisture out <strong>of</strong> the pulp.<br />

• Iron the paper pulp dry. Remove the blotting-paper carefully.<br />

• If the paper curls you may need <strong>to</strong> lay it flat under a heavy book for a<br />

few days until thoroughly cured<br />

From these instructions, it is obvious that <strong>papermaking</strong> is strongly coupled <strong>to</strong><br />

fluid <strong>mechanics</strong>: it is a <strong>fibre</strong> suspension flow (non-New<strong>to</strong>nian and dependent<br />

on the pulping process); turbulent mixing e.g. for obtaining a homogenous suspension;<br />

the sheet forming process (building up a sheet <strong>of</strong> paper); application<br />

<strong>of</strong> shear flows (shaking) <strong>to</strong> control the orientation and distribution <strong>of</strong> the <strong>fibre</strong>s;<br />

pressing and drying, which includes mechanical and thermodynamic processes.<br />

The distribution <strong>of</strong> <strong>fibre</strong>s, fillers and fines in the final paper sheet is quantified<br />

as paper formation, i.e. as the degree <strong>of</strong> local basis weight variation. This<br />

is one <strong>of</strong> the most important quality aspects <strong>of</strong> the final product.<br />

Machines used in modern paper production always consist <strong>of</strong> the forming<br />

section (see Figure 1.1), the press section and a drying section. Depending<br />

on the paper (or board) product manufactured other unit processes, such as<br />

e.g. coating, can be added but these three are always present. As already<br />

mentioned, the basic principles used in making traditional handsheet paper<br />

1