Fluid mechanics of fibre suspensions related to papermaking - DiVA

Fluid mechanics of fibre suspensions related to papermaking - DiVA

Fluid mechanics of fibre suspensions related to papermaking - DiVA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1.1. THE SHEET FORMING PROCESS 3<br />

there are paper mills that use as little as 3 m 3 <strong>of</strong> water per <strong>to</strong>n <strong>of</strong> paper produced,<br />

compared <strong>to</strong> more than 100 m 3 per <strong>to</strong>n in days gone by.<br />

1.1. The sheet forming process<br />

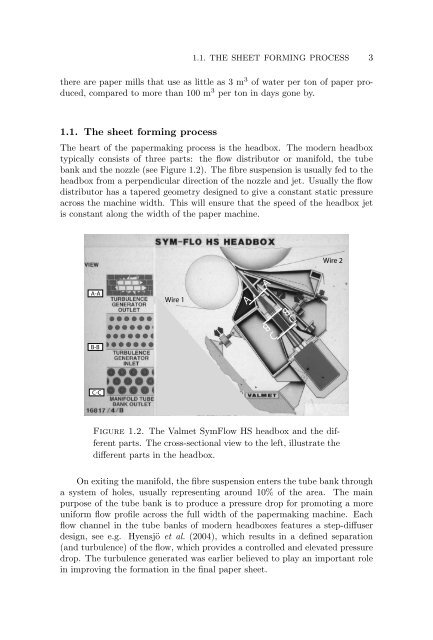

The heart <strong>of</strong> the <strong>papermaking</strong> process is the headbox. The modern headbox<br />

typically consists <strong>of</strong> three parts: the flow distribu<strong>to</strong>r or manifold, the tube<br />

bank and the nozzle (see Figure 1.2). The <strong>fibre</strong> suspension is usually fed <strong>to</strong> the<br />

headbox from a perpendicular direction <strong>of</strong> the nozzle and jet. Usually the flow<br />

distribu<strong>to</strong>r has a tapered geometry designed <strong>to</strong> give a constant static pressure<br />

across the machine width. This will ensure that the speed <strong>of</strong> the headbox jet<br />

is constant along the width <strong>of</strong> the paper machine.<br />

A-A<br />

B-B<br />

C-C<br />

Wire 1<br />

A A<br />

B B<br />

C C<br />

Wire 2<br />

Figure 1.2. The Valmet SymFlow HS headbox and the different<br />

parts. The cross-sectional view <strong>to</strong> the left, illustrate the<br />

different parts in the headbox.<br />

On exiting the manifold, the <strong>fibre</strong> suspension enters the tube bank through<br />

a system <strong>of</strong> holes, usually representing around 10% <strong>of</strong> the area. The main<br />

purpose <strong>of</strong> the tube bank is <strong>to</strong> produce a pressure drop for promoting a more<br />

uniform flow pr<strong>of</strong>ile across the full width <strong>of</strong> the <strong>papermaking</strong> machine. Each<br />

flow channel in the tube banks <strong>of</strong> modern headboxes features a step-diffuser<br />

design, see e.g. Hyensjö et al. (2004), which results in a defined separation<br />

(and turbulence) <strong>of</strong> the flow, which provides a controlled and elevated pressure<br />

drop. The turbulence generated was earlier believed <strong>to</strong> play an important role<br />

in improving the formation in the final paper sheet.