by Athena and Bill Steen - Cohabitat

by Athena and Bill Steen - Cohabitat

by Athena and Bill Steen - Cohabitat

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Perlite (or vermiculite)/light clay<br />

Perlite is mixed with a clay slip, either <strong>by</strong> h<strong>and</strong> or with a concrete<br />

or mortar mixer. Enough slip needs to be added so that the perlite<br />

binds together <strong>and</strong> that the mix has sufficient density. Like most facets<br />

of the earthen floor making process, experimentation will be needed<br />

to yield the proper proportions.<br />

Pumice fines (or other lightweight volcanic stone) can most<br />

likely be laid dry <strong>and</strong> tamped for good compaction.<br />

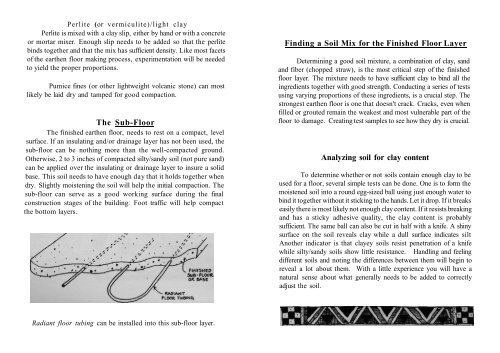

The Sub-Floor<br />

The finished earthen floor, needs to rest on a compact, level<br />

surface. If an insulating <strong>and</strong>/or drainage layer has not been used, the<br />

sub-floor can be nothing more than the well-compacted ground.<br />

Otherwise, 2 to 3 inches of compacted silty/s<strong>and</strong>y soil (not pure s<strong>and</strong>)<br />

can be applied over the insulating or drainage layer to insure a solid<br />

base. This soil needs to have enough day that it holds together when<br />

dry. Slightly moistening the soil will help the initial compaction. The<br />

sub-floor can serve as a good working surface during the final<br />

construction stages of the building. Foot traffic will help compact<br />

the bottom layers.<br />

Radiant floor tubing can be installed into this sub-floor layer.<br />

Finding a Soil Mix for the Finished Floor Layer<br />

Determining a good soil mixture, a combination of clay, s<strong>and</strong><br />

<strong>and</strong> fiber (chopped straw), is the most critical step of the finished<br />

floor layer. The mixture needs to have sufficient clay to bind all the<br />

ingredients together with good strength. Conducting a series of tests<br />

using varying proportions of these ingredients, is a crucial step. The<br />

strongest earthen floor is one that doesn't crack. Cracks, even when<br />

filled or grouted remain the weakest <strong>and</strong> most vulnerable part of the<br />

floor to damage. Creating test samples to see how they dry is crucial.<br />

Analyzing soil for clay content<br />

To determine whether or not soils contain enough clay to be<br />

used for a floor, several simple tests can be done. One is to form the<br />

moistened soil into a round egg-sized ball using just enough water to<br />

bind it together without it sticking to the h<strong>and</strong>s. Let it drop. If it breaks<br />

easily there is most likely not enough clay content. If it resists breaking<br />

<strong>and</strong> has a sticky adhesive quality, the clay content is probably<br />

sufficient. The same ball can also be cut in half with a knife. A shiny<br />

surface on the soil reveals clay while a dull surface indicates silt<br />

Another indicator is that clayey soils resist penetration of a knife<br />

while silty/s<strong>and</strong>y soils show little resistance. H<strong>and</strong>ling <strong>and</strong> feeling<br />

different soils <strong>and</strong> noting the differences between them will begin to<br />

reveal a lot about them. With a little experience you will have a<br />

natural sense about what generally needs to be added to correctly<br />

adjust the soil.