INSTRUCTION AND MAINTENANCE MANUAL FOR ... - Jabiru Aircraft

INSTRUCTION AND MAINTENANCE MANUAL FOR ... - Jabiru Aircraft

INSTRUCTION AND MAINTENANCE MANUAL FOR ... - Jabiru Aircraft

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Jabiru</strong> <strong>Aircraft</strong> Pty Ltd<br />

Instruction & Maintenance Manual<br />

<strong>Jabiru</strong> 3300 <strong>Aircraft</strong> Engine<br />

Hydraulic Valve Lifter Models<br />

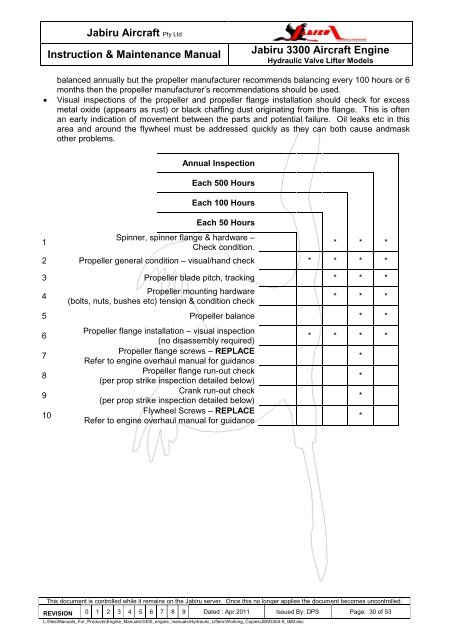

balanced annually but the propeller manufacturer recommends balancing every 100 hours or 6<br />

months then the propeller manufacturer‟s recommendations should be used.<br />

Visual inspections of the propeller and propeller flange installation should check for excess<br />

metal oxide (appears as rust) or black chaffing dust originating from the flange. This is often<br />

an early indication of movement between the parts and potential failure. Oil leaks etc in this<br />

area and around the flywheel must be addressed quickly as they can both cause andmask<br />

other problems.<br />

1<br />

Annual Inspection<br />

Each 500 Hours<br />

Each 100 Hours<br />

Each 50 Hours<br />

Spinner, spinner flange & hardware –<br />

Check condition.<br />

This document is controlled while it remains on the <strong>Jabiru</strong> server. Once this no longer applies the document becomes uncontrolled.<br />

REVISION 0 1 2 3 4 5 6 7 8 9 Dated : Apr 2011 Issued By: DPS Page: 30 of 53<br />

L:\files\Manuals_For_Products\Engine_Manuals\3300_engine_manuals\Hydraulic_Lifters\Working_Copies\JEM3304-9_I&M.doc<br />

* * *<br />

2 Propeller general condition – visual/hand check * * * *<br />

3 Propeller blade pitch, tracking * * *<br />

4<br />

Propeller mounting hardware<br />

(bolts, nuts, bushes etc) tension & condition check<br />

* * *<br />

5 Propeller balance * *<br />

6<br />

7<br />

8<br />

9<br />

10<br />

Propeller flange installation – visual inspection<br />

(no disassembly required)<br />

Propeller flange screws – REPLACE<br />

Refer to engine overhaul manual for guidance<br />

Propeller flange run-out check<br />

(per prop strike inspection detailed below)<br />

Crank run-out check<br />

(per prop strike inspection detailed below)<br />

Flywheel Screws – REPLACE<br />

Refer to engine overhaul manual for guidance<br />

* * * *<br />

*<br />

*<br />

*<br />

*