bulletin - Siempelkamp

bulletin - Siempelkamp

bulletin - Siempelkamp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The printing and packaging industry, as<br />

one example, is acquiring parts with a<br />

lighter weight and a smaller size when<br />

compared to the classic foundry products.<br />

The market is making specific demands:<br />

“Demands on the folding carton market<br />

are getting tougher all the time. Competition<br />

is intensifying, runs are getting<br />

shorter, and cost pressure is increasing.<br />

Customers are looking for ever quicker and<br />

better results at ever lower prices. They also<br />

expect a higher level of customization.<br />

Innovative carton designs aimed at specific<br />

target groups are being increasingly used to<br />

make products stand out at the point of<br />

sale,” Stefan Mettler, Managing Director of<br />

<strong>Siempelkamp</strong> Foundry, describes.<br />

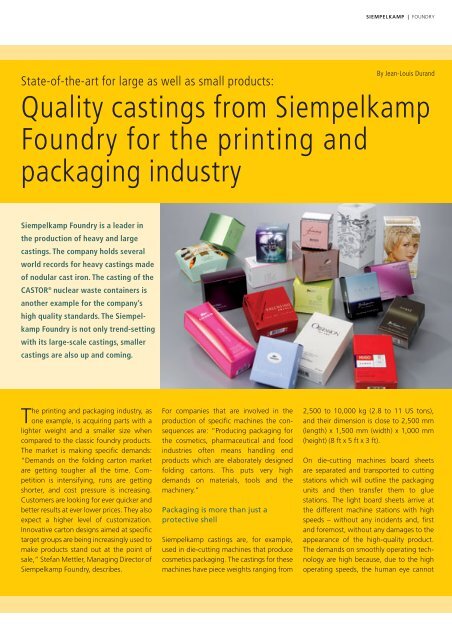

For companies that are involved in the<br />

production of specific machines the consequences<br />

are: “Producing packaging for<br />

the cosmetics, pharmaceutical and food<br />

industries often means handling end<br />

products which are elaborately designed<br />

folding cartons. This puts very high<br />

demands on materials, tools and the<br />

machinery.”<br />

Packaging is more than just a<br />

protective shell<br />

<strong>Siempelkamp</strong> castings are, for example,<br />

used in die-cutting machines that produce<br />

cosmetics packaging. The castings for these<br />

machines have piece weights ranging from<br />

SIEMPELKAMP | FOUNDRY<br />

By Jean-Louis Durand<br />

State-of-the-art for large as well as small products:<br />

Quality castings from <strong>Siempelkamp</strong><br />

Foundry for the printing and<br />

packaging industry<br />

<strong>Siempelkamp</strong> Foundry is a leader in<br />

the production of heavy and large<br />

castings. The company holds several<br />

world records for heavy castings made<br />

of nodular cast iron. The casting of the<br />

CASTOR ® nuclear waste containers is<br />

another example for the company’s<br />

high quality standards. The Siempel-<br />

kamp Foundry is not only trend-setting<br />

with its large-scale castings, smaller<br />

castings are also up and coming.<br />

2,500 to 10,000 kg (2.8 to 11 US tons),<br />

and their dimension is close to 2,500 mm<br />

(length) x 1,500 mm (width) x 1,000 mm<br />

(height) (8 ft x 5 ft x 3 ft).<br />

On die-cutting machines board sheets<br />

are separated and transported to cutting<br />

stations which will outline the packaging<br />

units and then transfer them to glue<br />

stations. The light board sheets arrive at<br />

the different machine stations with high<br />

speeds – without any incidents and, first<br />

and foremost, without any damages to the<br />

appearance of the high-quality product.<br />

The demands on smoothly operating technology<br />

are high because, due to the high<br />

operating speeds, the human eye cannot