bulletin - Siempelkamp

bulletin - Siempelkamp

bulletin - Siempelkamp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Europipe pipes have to meet high demands. Used as<br />

pipeline pipes they have to withstand extremely high and low<br />

temperatures as well as extreme pressures. The market demands<br />

pipes with a high wall thickness as well as an increasingly specific<br />

geometry. This development requires an optimal forming process<br />

of the sheet metal which begins with the crimping press. “For<br />

the production of pipes, high press loads over long periods of time<br />

are necessary. This was the reason for us to replace, after more<br />

than 30 years, our existing crimping press with a stronger<br />

press incorporating a new design. In our eyes, <strong>Siempelkamp</strong>, an<br />

experienced manufacturer in the area of crimping presses, has<br />

been the right partner,” says Hans-Heinrich Meier, manager of<br />

maintenance and repair at Europipe.<br />

Sigfrid Buecher, project manager for <strong>Siempelkamp</strong>’s metal forming<br />

division has the following to add: “This order confronted us with<br />

the task of guaranteeing our customers improved and repeatable<br />

forming results even for high-strength sheet metal. For us this<br />

large project included numerous challenges which had to be solved<br />

within a short time and to which we dedicated all our resources.”<br />

Part of the scope of supply, next to the crimping press, was the<br />

complete hydraulic system as well as the retrofitting of the existing<br />

roller conveyors. The shop assembly of the new press in the<br />

<strong>Siempelkamp</strong> production hall and the disassembly of the old<br />

existing press were also carried out by <strong>Siempelkamp</strong> as part of the<br />

Europipe order.<br />

Design: patented quality<br />

SIEMPELKAMP | MACHINERY AND PLANTS<br />

In April 2007 Europipe commissioned <strong>Siempelkamp</strong>’s machinery and plant business division with the production of<br />

a crimping press. Europipe, located in Mülheim, Germany, is a specialist for welded steel pipes used under extreme<br />

loads. The technology, size and production timeline for the new crimping press made the company decide to go with<br />

<strong>Siempelkamp</strong> as the manufacturer. A good decision because the crimping press, now operating since August 2008,<br />

has been commended as a masterstroke in many ways by the customer.<br />

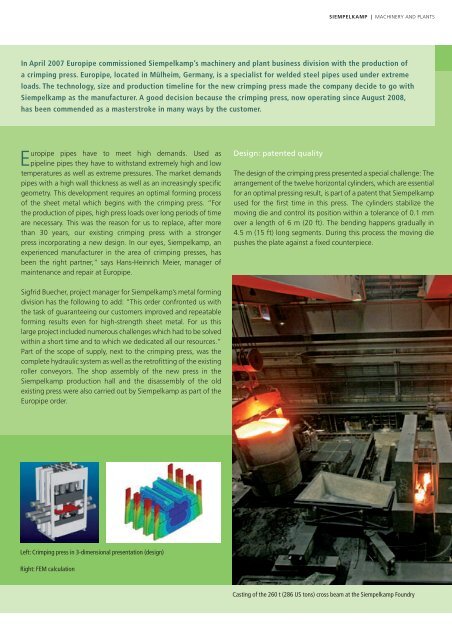

Left: Crimping press in 3-dimensional presentation (design)<br />

Right: FEM calculation<br />

The design of the crimping press presented a special challenge: The<br />

arrangement of the twelve horizontal cylinders, which are essential<br />

for an optimal pressing result, is part of a patent that <strong>Siempelkamp</strong><br />

used for the first time in this press. The cylinders stabilize the<br />

moving die and control its position within a tolerance of 0.1 mm<br />

over a length of 6 m (20 ft). The bending happens gradually in<br />

4.5 m (15 ft) long segments. During this process the moving die<br />

pushes the plate against a fixed counterpiece.<br />

Casting of the 260 t (286 US tons) cross beam at the <strong>Siempelkamp</strong> Foundry