(70) Therefore, the risk of sulphuric acid dew point attack ... - DTI Home

(70) Therefore, the risk of sulphuric acid dew point attack ... - DTI Home

(70) Therefore, the risk of sulphuric acid dew point attack ... - DTI Home

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

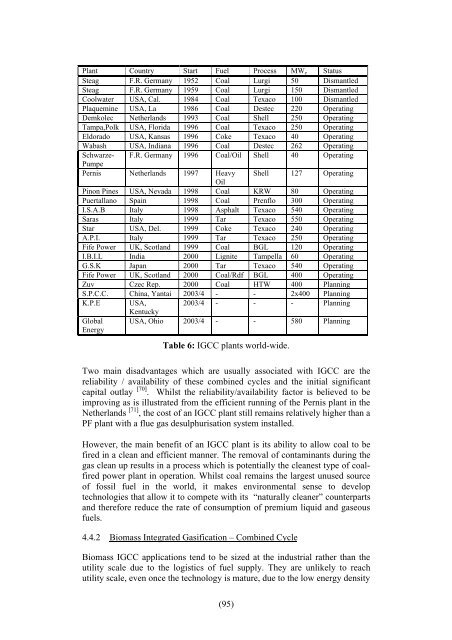

Plant Country Start Fuel Process MWe Status<br />

Steag F.R. Germany 1952 Coal Lurgi 50 Dismantled<br />

Steag F.R. Germany 1959 Coal Lurgi 150 Dismantled<br />

Coolwater USA, Cal. 1984 Coal Texaco 100 Dismantled<br />

Plaquemine USA, La 1986 Coal Destec 220 Operating<br />

Demkolec Ne<strong>the</strong>rlands 1993 Coal Shell 250 Operating<br />

Tampa,Polk USA, Florida 1996 Coal Texaco 250 Operating<br />

Eldorado USA, Kansas 1996 Coke Texaco 40 Operating<br />

Wabash USA, Indiana 1996 Coal Destec 262 Operating<br />

Schwarze-<br />

Pumpe<br />

F.R. Germany 1996 Coal/Oil Shell 40 Operating<br />

Pernis Ne<strong>the</strong>rlands 1997 Heavy Shell 127 Operating<br />

Oil<br />

Pinon Pines USA, Nevada 1998 Coal KRW 80 Operating<br />

Puertallano Spain 1998 Coal Prenflo 300 Operating<br />

I.S.A.B Italy 1998 Asphalt Texaco 540 Operating<br />

Saras Italy 1999 Tar Texaco 550 Operating<br />

Star USA, Del. 1999 Coke Texaco 240 Operating<br />

A.P.I. Italy 1999 Tar Texaco 250 Operating<br />

Fife Power UK, Scotland 1999 Coal BGL 120 Operating<br />

I.B.I.L India 2000 Lignite Tampella 60 Operating<br />

G.S.K Japan 2000 Tar Texaco 540 Operating<br />

Fife Power UK, Scotland 2000 Coal/Rdf BGL 400 Operating<br />

Zuv Czec Rep. 2000 Coal HTW 400 Planning<br />

S.P.C.C. China, Yantai 2003/4 - - 2x400 Planning<br />

K.P.E USA, 2003/4 - - - Planning<br />

Global<br />

Energy<br />

Kentucky<br />

USA, Ohio 2003/4 - - 580 Planning<br />

Table 6: IGCC plants world-wide.<br />

Two main disadvantages which are usually associated with IGCC are <strong>the</strong><br />

reliability / availability <strong>of</strong> <strong>the</strong>se combined cycles and <strong>the</strong> initial significant<br />

capital outlay [<strong>70</strong>] . Whilst <strong>the</strong> reliability/availability factor is believed to be<br />

improving as is illustrated from <strong>the</strong> efficient running <strong>of</strong> <strong>the</strong> Pernis plant in <strong>the</strong><br />

Ne<strong>the</strong>rlands [71] , <strong>the</strong> cost <strong>of</strong> an IGCC plant still remains relatively higher than a<br />

PF plant with a flue gas desulphurisation system installed.<br />

However, <strong>the</strong> main benefit <strong>of</strong> an IGCC plant is its ability to allow coal to be<br />

fired in a clean and efficient manner. The removal <strong>of</strong> contaminants during <strong>the</strong><br />

gas clean up results in a process which is potentially <strong>the</strong> cleanest type <strong>of</strong> coalfired<br />

power plant in operation. Whilst coal remains <strong>the</strong> largest unused source<br />

<strong>of</strong> fossil fuel in <strong>the</strong> world, it makes environmental sense to develop<br />

technologies that allow it to compete with its “naturally cleaner” counterparts<br />

and <strong>the</strong>refore reduce <strong>the</strong> rate <strong>of</strong> consumption <strong>of</strong> premium liquid and gaseous<br />

fuels.<br />

4.4.2 Biomass Integrated Gasification – Combined Cycle<br />

Biomass IGCC applications tend to be sized at <strong>the</strong> industrial ra<strong>the</strong>r than <strong>the</strong><br />

utility scale due to <strong>the</strong> logistics <strong>of</strong> fuel supply. They are unlikely to reach<br />

utility scale, even once <strong>the</strong> technology is mature, due to <strong>the</strong> low energy density<br />

(95)