The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

132 THE LOCOMOTIVE. [September,<br />

collect until the state of things shown in the cut was the result. This pipe is an inch<br />

and a quarter in diameter, internally, and it was stopped up by the deposit until only a<br />

small triangular hole was left, the area of which is about jfe of a square inch.<br />

Fig. 2 shows another feed-pipe in which the deposit was of a similar character,<br />

except that it extended back from the end of the pipe to a considerable distance. <strong>The</strong><br />

history of this pipe is substantially the same as that of the preceding one. In each case<br />

the engineer in charge of the plant thought the difficulty was with the pumps, which<br />

and in each case investigation<br />

could not be made to run fast enough to feed the boilers ;<br />

showed that the pump was all right, and proved that the trouble lay in the feed-pipe.<br />

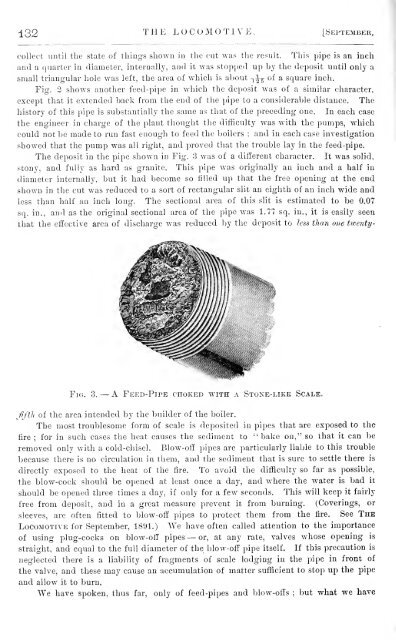

<strong>The</strong> deposit in the pipe shown in Fig. 3 was of a different character. It was solid,<br />

stony, and fully as hard as granite. This pipe was originally an inch and a half in<br />

diameter internally, but it had become so filled up that the free opening at the end<br />

shown in the cut was reduced to a sort of rectangular slit an eighth of an inch wide and<br />

less than half an inch long. <strong>The</strong> sectional area of this slit is estimated to be 0.07<br />

sq. in., and as the original sectional area of the pipe was 1.77 sq. in., it is easily seen<br />

that the effective area of discharge was reduced by the deposit to less than one twenty-<br />

Fig. 3. — A Feed-Pipe choked with a Stone-like Scale.<br />

fifth of the area intended by the builder of the boiler.<br />

<strong>The</strong> most troublesome form of scale is deposited in pipes that are exposed to the<br />

fire ; for in such cases the heat causes the sediment to "bake on," so that it can be<br />

removed only with a cold-chisel. Blow-off pipes are particularly liable to this trouble<br />

because there is no circulation in them, and the sediment that is sure to settle there is<br />

directly exposed to the heat of the fire. To avoid the difficulty so far as possible,<br />

the blow-cock should be opened at least once a day, and where the water is bad it<br />

should be opened three times a day, if only for a few seconds. This will keep it fairly<br />

free from deposit, and in a great measure prevent it from burning. (Coverings, or<br />

sleeves, are often fitted to blow-off pipes to protect them from the fire. See <strong>The</strong><br />

<strong>Locomotive</strong> for September, 1891.) We have often called attention to the importance<br />

of using plug-cocks on blow-off pipes — or, at any rate, valves whose opening is<br />

straight, and equal to the full diameter of the blow-off pipe itself. If this precaution is<br />

neglected there is a liability of fragments of scale lodging in the pipe in front of<br />

the valve, and these may cause an accumulation of matter sufficient to stop up the pipe<br />

and allow it to burn.<br />

We have spoken, thus far, only of feed-pipes and blow-offs ; but what we have