The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

:<br />

1894.] THE LOCOMOTIVE. 163<br />

In order to provide againsl the breaking of cast-iron flanges care should be taken t<br />

make them abundantly thick; or, which we consider a better plan, they may be made<br />

with bracket* running from the flange to the body of the casting al frequent intervals, as<br />

shown in Fig. 9. <strong>The</strong> cover 1 » may * : flat, if it is made thick enough, but it is much<br />

better to provide ribs on the upper side of it, as in Fig. 2. Such ribs possess great stif-<br />

fening power and add much more to the strength of the cover than the same amount of<br />

metal would if distributed in any Other way. When the covers of digesters and bleach-<br />

ers have to be frequently removed, it is usual to slot the bolt-holes so that the bolts can<br />

be removed by merely loosening the nuts. <strong>The</strong>y are also frequently so arranged that<br />

each bolt turns about a horizontal pin that passes through holes in a pair of parallel<br />

bracket- casl on the body of the mouth-piece. <strong>The</strong> discussion of the features is reserved<br />

for a future i->ue, however, as we are here concerned merely with the strength of cast-<br />

iron flanges.<br />

<strong>The</strong> reasoning that we have given in connection with mouth-piece flanges is also<br />

applicable to the cast-iron flanges used in connecting large steampipes that are designed<br />

to carry heavy pressures. Figs. 3 and 4 show a front view and a sectional view of a<br />

bracketted flange connection as designed for a ten-inch steam main, and a design substan-<br />

tially similar may be used for other sizes of pipe.<br />

Inspectors' Report.<br />

September, 1894.<br />

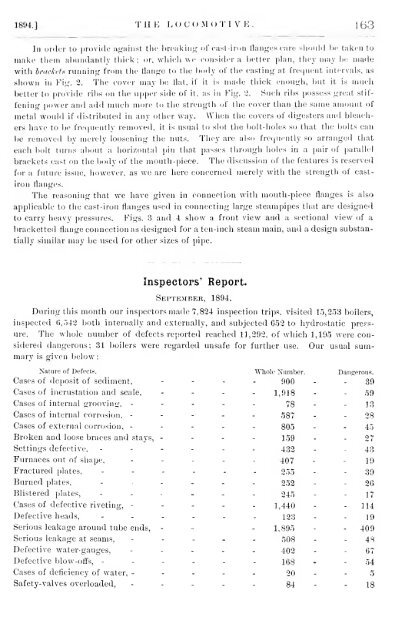

During this month our inspectors made 7,824 inspection trips, visited 15,253 boilers,<br />

inspected 6,542 both internally and externally, and subjected 652 to hydrostatic press-<br />

ure. <strong>The</strong> whole number of defects reported reached 11,292, of which 1,195 were con-<br />

sidered dangerous; 31 boilers were regarded unsafe for further use. Our usual summary<br />

is given below<br />

Nature of Defects.<br />

Whole Number.<br />

Cases of deposit of sediment, ...<br />

Cases of incrustation and scale, ...<br />

....<br />

Cases of internal grooving, -<br />

Cases of internal corrosion.<br />

Cases of external corrosion, -<br />

Broken and loose braces and stays, ...<br />

..... ....<br />

Settings defective, -<br />

Furnaces out of shape,<br />

.....<br />

Fractured plates,<br />

Burned plates,<br />

-<br />

.....<br />

Blistered plates,<br />

Cases of defective riveting, -<br />

Defective heads,<br />

Serious leakage around tube ends, -<br />

Serious leakage at seams, -<br />

Defective water-gauges, -<br />

Defective blow-offs, -<br />

Cases of deficiency of water, -<br />

Safety-valves overloaded, -