Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

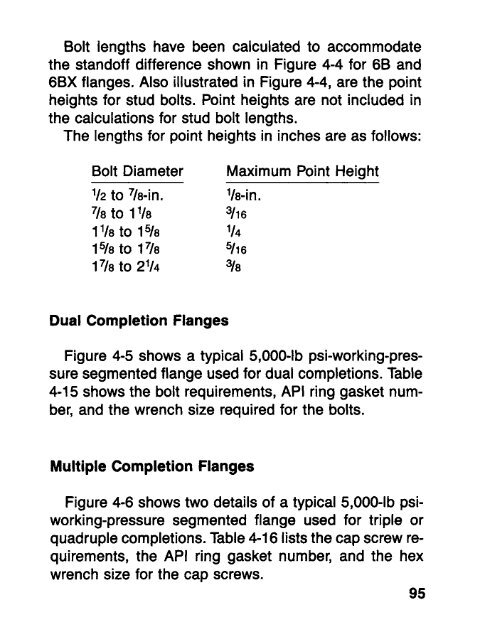

Bolt lengths have been calculated <strong>to</strong> accommodate<br />

the standoff difference shown in Figure 4-4 for 6B and<br />

6BX flanges. Also illustrated in Figure 4-4, are the point<br />

heights for stud bolts. Point heights are not included in<br />

the calculations for stud bolt lengths.<br />

The lengths for point heights in inches are as follows:<br />

Bolt Diameter Maximum Point Height<br />

1/2 <strong>to</strong> 7/s-in. Vs-in.<br />

7/8 <strong>to</strong> 1VB 3/16<br />

1118 <strong>to</strong> 15/8 1/4<br />

1% <strong>to</strong> 1718 5/16<br />

17/8 <strong>to</strong> 21/4 3/8<br />

Dual Completion <strong>Flan</strong>ges<br />

Figure 4-5 shows a typical 5,000-1b psi-working-pres-<br />

sure segmented flange used for dual completions. Table<br />

4-15 shows the bolt requirements, API ring gasket num-<br />

ber, and the wrench size required for the bolts.<br />

Multiple Completion <strong>Flan</strong>ges<br />

Figure 4-6 shows two details of a typical 5,000-1b psi-<br />

working-pressure segmented flange used for triple or<br />

quadruple completions. Table 4-16 lists the cap screw re-<br />

quirements, the API ring gasket number, and the hex<br />

wrench size for the cap screws.<br />

95