Spectroscopic Ellipsometry (Sopra GES 5) - Login | Nanolab, UCLA

Spectroscopic Ellipsometry (Sopra GES 5) - Login | Nanolab, UCLA

Spectroscopic Ellipsometry (Sopra GES 5) - Login | Nanolab, UCLA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

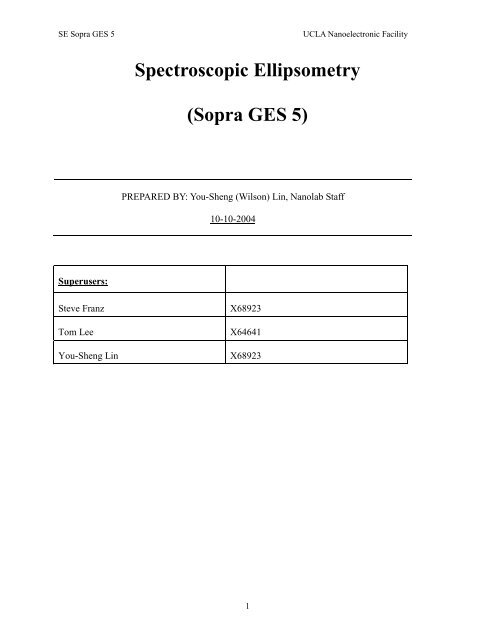

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

Superusers:<br />

<strong>Spectroscopic</strong> <strong>Ellipsometry</strong><br />

(<strong>Sopra</strong> <strong>GES</strong> 5)<br />

PREPARED BY: You-Sheng (Wilson) Lin, <strong>Nanolab</strong> Staff<br />

10-10-2004<br />

Steve Franz X68923<br />

Tom Lee X64641<br />

You-Sheng Lin X68923<br />

1

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

I. Introduction<br />

A. Principle<br />

<strong>Spectroscopic</strong> ellipsometry (SE) is a non-contact, non-destructive optical technique that<br />

enables the determination of material refractive indices and layer thicknesses by<br />

measuring the change in polarization of a probing light beam upon reflection from a<br />

sample. When linearly polarized light reflects from a surface, elliptically polarized light<br />

is generated under certain conditions. The amount of induced ellipticity depends on the<br />

surface properties (refractive index, bulk or layered sample…). <strong>Ellipsometry</strong> technique<br />

measures the phase and amplitude relationships between two orthogonal polarizations (p<br />

and s waves) upon reflection. When p and s waves are reflected, they experience a phase<br />

shift and an amplitude reduction (not necessarily the same for both waves). The<br />

ellipsometric parameter Delta is defined as d1 - d2 where d1 and d2 denotes the induced<br />

phase shift difference between p and s waves, respectively while the ellipsometric<br />

parameter tan(Psi) is defined as the ratio of the complex amplitude of the total reflection<br />

coefficient of the p and s waves ( |RP| / |RS| ). <strong>Ellipsometry</strong> is said to be self-referencing<br />

because measurements do not require any reference sample and are largely insensitive to<br />

variations in the beam intensity and ambient environment, making this technique highly<br />

accurate and reproducible.<br />

B. Instrumentation<br />

The <strong>Sopra</strong> <strong>GES</strong> 5 spectroscopic ellipsometer allows for variable-angle broadband<br />

spectroscopic ellipsometry. It covers a spectral range from 210 nm to 900 nm. And<br />

2

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

upgradable for wider spectal range in DUV, NIR, and IR ranges. The UV/Visible/NIR<br />

source is a Xenon lamp whose maximum of intensity is located at 450 nm. Two<br />

attenuators are available corresponding to an attenuation of 17 % and 7 % respectively<br />

and the system can be set to automatically remove them during a measurement when the<br />

intensity is very low in order to improve the signal to noise ratio. Our configuration in the<br />

UV-Visible-NIR spectrum is rotating polarizer - fixed analyzer ellipsometry. When the<br />

polarizer rotates, the incident beam is linearly polarized with a direction that rotates in<br />

time. After reflection on the sample, the light is elliptically polarized with its axis<br />

rotating in time. After the analyzer, the light is again linearly polarized with a fixed<br />

direction and a time dependent amplitude. The advantage of this technique is that the<br />

measurement is not affected by the polarization sensitivity of the detector (fixed<br />

polarization) but it requires a perfectly randomly polarized incident beam. The beam size<br />

is typically between 1 mm 2 and 10 mm 2 depending on the aperture. The variable angles<br />

are from 7º to 90º with variable +/- 0.01º.<br />

C. Analysis<br />

The ellipsometric parameters are fitted using the Levenberg-Marquardt regression<br />

method. Different models are available to describe the dispersion relation of the refractive<br />

index of the measured materials including the Gaussian and Lorentz oscillator models,<br />

the Cauchy and Sellmeir laws, the Kramers-Kronig relations, the Forouhi interband<br />

model, the model dielectric function, the Drude model... Point to point calculation (i.e.<br />

calculation of the n and k values from the data at each wavelength for a single layer of<br />

known thickness) is also possible. In addition, whenever the sample is bulk or can be<br />

3

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

treated as such because of its strong absorption, the dispersion relation is simply obtained<br />

by direct calculation of n and k at all wavelengths without any assumption.<br />

II. Operating Procedure<br />

A. Define the spectral range for the measurement<br />

This procedure will help users to define measurement parameters before starting a<br />

measurement.<br />

1) Definition of the spectral range<br />

• Open Winelli<br />

• Go to File and select Simulation.<br />

The Simulation Parameters Window appears.<br />

• Select Model to define the structure that you will simulate<br />

a. In the folder “Structure”:<br />

• Make sure the Layer type is material<br />

• Add or subtract desire layers<br />

• Click the each layer, and select the material data from the files (by click on the<br />

4

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

blank space) for the appropriate N.K file. Also, enter the composition and<br />

concentrations if applicable.<br />

• Enter the thickness of the film and by checking the box next to the thickness<br />

will try to fit the thickness close to the estimate thickness.<br />

b. In the folder “Boundaries”:<br />

• Make sure the WaveLength is Variable and Unit is µm.<br />

• Define the first, the last wavelengths and the number of points for the<br />

measurements. Initiate with the visible spectrum (0.3 µm- 0.8 µm) and 200 points<br />

to describe precisely the sample.<br />

• Enter the incidence angle that you will use during the measurement (use 75º).<br />

5

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

c. In the folder “Special”:<br />

• Check the microspot box (the aperture typically equals 2.0). If you don’t want to<br />

use microspot, please ask staff or superusers for assistant.<br />

• Then press Run. You will come back to the Simulation Parameters Window.<br />

• Press Simulation to plot tan(ψ) and cos(∆) (for the structure you defined in<br />

‘Model’)<br />

6

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

• Go back to the Simulation Parameters Window. Change the Output (in the right<br />

bottom corner) from graphic to spreadsheet.<br />

• Press Simulation one more time to obtain the values of tan (ψ) and cos (∆) in an<br />

array.<br />

Go to Analysis and select Adjustment. This mode gives you the possibility to change<br />

manually the parameters of your model.<br />

7

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

• The ‘structure’ screen appears. Check the parameters that you want to vary manually (Thickness,<br />

concentration, …).<br />

• Press Run<br />

• Now, you can adjust manually by using the slide or typing a number, every parameter<br />

checked in the structure.<br />

• So you are able to define the spectral range where the measurements are the most<br />

8

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

sensitive to parameters variations.<br />

• Then save and exit. (A window should appear concerning the regression. Don’t take<br />

care of it, and select the Simulation Parameters Window)<br />

2) Definition of the optimum number of wavelengths for the measurement<br />

B. Sample alignment Procedure<br />

• Open Gespack by double click the Gespack icon<br />

User: Engineer<br />

Password: <strong>Sopra</strong><br />

1. Place the wafer on the sample stage<br />

2. Make sure the stage is low enough for 75º by lowering the Z<br />

stage.<br />

3. Click on the Show<br />

4. Change the parameter values :<br />

a. λ : the most intense wavelength 0.45 micron<br />

b. Angle of analyzer : 45°<br />

c. Plan of incidence: 75°<br />

5. Press Run (Wait for 1 minute, and the count, signal.......)<br />

6. Adjust the Z position to obtain maximum of signal<br />

7. Attenuators On as required to keep signal around 10 millions<br />

9

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

8. If the signal is below 5 millions counts, open the slit (right hand side under the table)<br />

to get 10 millions.<br />

9. Adjust the tilt of the sample holder (with both screws) to obtain the maximum signal<br />

and to obtain a symmetry between -1 and +1 if needed.<br />

10. Turn the Attenuators ON as required to keep signal around 10 millions<br />

11. Adjust the Z position again to obtain maximum signal<br />

12. Turn the Attenuators ON as required to keep signal around 10 millions<br />

13. Adjust the slit of the spectrometer to obtain 10 millions.<br />

14. If the slit is fully opened and you don’t have 10 millions, the let the slit fully opened<br />

15. Stop and Exit<br />

• Parameters for the measurement<br />

Analyzer Position Mode (Please make sure that all the following parameters are correct<br />

and don’t change anything unless you discuss with superuser or staff)<br />

In the “Polarisation/Geometry folder”,<br />

Previous tracking: Adjust the analyzer position at ψ where tan ψ is the first<br />

ellipsometric parameter of the previous measurement. More usual mode to<br />

make measurements. You need to put a starting position different than zero<br />

(45 is good). Does not work for very thick samples and a low number of<br />

points (when tan ψ is closed to 0, ψ is closed to 0, so the analyzer position<br />

will be at 0)<br />

10

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

Incidence angle<br />

Fixed: at the indicated position all along the measurement<br />

Use of calibrated angel: Yes<br />

Theory Angel: 75 and Mea. 75.2<br />

In the “Time and wavelength” folder,<br />

Integration time<br />

Variable: The integration time can change depending on the number of<br />

counts on the detector. The measurement stop is the number of counts<br />

exceed a given value (generally 4 000 000) of a given time (generally 10s or<br />

5s)<br />

Spectrometer position<br />

Scanned: for spectroscopic measurement. Enter the values obtained in step 1<br />

Unit: µm<br />

From the simulated result, put correct set to get right measurement duration.<br />

(Ex: From 0.25 to 0.85; step: 0.003 Number of points = 200)<br />

Background noise<br />

In the “Other” folder,<br />

Meas/Scan: measured at the beginning of each scan<br />

11

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

Signal correction<br />

Special<br />

Non Linearity + polarization: makes correction of the non linearity of the<br />

detector and of the residual polarization using the values calibrated in the<br />

GETEST software (Mostly used)<br />

Use attenuators: Checked when you adjust the signal on the detector with<br />

both attenuators (Used for optimized the measurement and reduce the noise)<br />

Microspots<br />

Press Run/Accept<br />

C. Start the Measurement<br />

1. By click the Run bottom<br />

2. Depending on the number of data points, it will take up to 20 minutes.<br />

3. At the end of the measurement, save it and analyze it with the software WINELLI<br />

III. Analysis of the data<br />

A. Thickness measurement analysis<br />

1. Open Winelli software<br />

2. Open last measurement data (filename.dat)<br />

12

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

3. Enter in Analysis menu and Select Regression.<br />

4. Define the structure of your film mixed with void (void.nk)<br />

5. Fit on the thickness of the film and on the concentration of void. Click Run the<br />

regression using function “cos(2psi) and sin(2psi)*cos(delta)” (if you have film<br />

> 500 A) mode.<br />

6. Examine the curve<br />

7. Save and print the regression results.<br />

8. You can fine the thickness data from the table.<br />

B. Analysis using a Cauchy dispersion law (for better fitting, optional)<br />

1. Go back to the Structure screen (Right next to Run on the top)<br />

2. Change the “layer type” into dispersion law and click on “Law parameters”.<br />

3. Select Standard Dielectric Function, UV term, and Cauchy (n,k). Ex: For oxide<br />

films, enter as started values 1.45 for A, 0.01 for B and fit on the three parameters<br />

A,B,C.<br />

4. Fit on the thickness for films. Run the regression using “cos(2psi) and<br />

sin(2psi)*cos(delta)” mode.<br />

5. Examine the curve and fit.<br />

6. Save and Print the regression.<br />

7. Bo back to the structure screen and in law parameter screen. Save the refractive<br />

index as Cauchy.nk.<br />

8. Exit the regression.<br />

13

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

Appendix:<br />

In the Analyzer<br />

In the “Polarisation/Geometry folder”,<br />

Previous tracking: Adjust the analyzer position at ψ where tan ψ is the first<br />

ellipsometric parameter of the previous measurement. More usual mode to<br />

make measurements. You need to put a starting position different than zero<br />

(45 is good). Does not work for very thick samples and a low number of<br />

points (when tan ψ is closed to 0, ψ is closed to 0, so the analyzer position<br />

will be at 0)<br />

Current tracking: At each step make a first measurement to found tan ψ and<br />

then adjust the analyzer position to ψ. Best accuracy but the measurement is<br />

increased.<br />

Limited tracking: Same mode as previous tracking but the minimum angle<br />

will be 5 degrees. Avoid to have an analyzer position to 0.<br />

Fixed: at the indicated position all along the measurement (not optimized for<br />

accuracy)<br />

14

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

Incidence angle<br />

Scanned: The angle of incidence is scanned during the measurement.<br />

Fixed: at the indicated position all along the measurement<br />

Use of calibrated angel: Yes<br />

Theory Angel: 75 and Mea. 75.2<br />

In the “Time and wavelength” folder,<br />

Integration time<br />

Scanned: You can repeat the same measurement with a given time step (only<br />

interesting for non stable samples).<br />

Fixed: at the indicated value all along the measurement (non optimized)<br />

Variable: The integration time can change depending on the number of<br />

counts on the detector. The measurement stop is the number of counts<br />

exceed a given value (generally 4 000 000) of a given time (generally 10s or<br />

5s)<br />

SNR: You must indicate the integration time for one measurement, a target<br />

value for the SNR, and a maximum number of iterations<br />

15

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

Spectrometer position<br />

Scanned: for spectroscopic measurement. Enter the values obtained in step 1<br />

Unit: µm<br />

From the simulated result, put correct set to get right measurement duration.<br />

(Ex: From 0.25 to 0.85; step: 0.003 Number of points = 200)<br />

Fixed: at the indicated position all along the measurement (variable angle<br />

measurement for example)<br />

In both case, the measurement can be done in eV, µm, nm or cm -1 .<br />

Background noise<br />

In the “Other” folder,<br />

Default: fixed at the indicated value (counts/s).<br />

Meas/Scan: measured at the beginning of each scan<br />

Meas/Int: measured before each measurement<br />

16

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

Signal correction<br />

Special<br />

No correction: no correction for the measured signal (no optimized)<br />

Non Linearity: makes correction of the non linearity of the detector using<br />

the values calibrated in the GETEST software<br />

Non Linearity + polarization: makes correction of the non linearity of the<br />

detector and of the residual polarization using the values calibrated in the<br />

GETEST software (Mostly used)<br />

Use attenuators: Checked when you adjust the signal on the detector with<br />

both attenuators (Used for optimized the measurement and reduce the noise)<br />

Use Microspots<br />

Mirror analyzer: make twice the measurement at A and –A for the analyzer<br />

position (used only for the calibration)<br />

Init Spectrometer: makes an initialization of the spectrometer before each<br />

scanning measurement<br />

Init Goniometer: makes an initialization of the goniometer each scanning<br />

17

SE <strong>Sopra</strong> <strong>GES</strong> 5 <strong>UCLA</strong> Nanoelectronic Facility<br />

measurement<br />

Compensator: only available if compensator option is checked in the setup<br />

of the instrument<br />

18