Layered Process Audits (LPA) - Chrysler

Layered Process Audits (LPA) - Chrysler

Layered Process Audits (LPA) - Chrysler

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

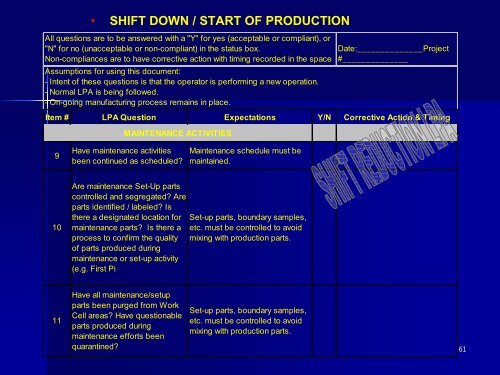

Date:______________Project<br />

#______________<br />

Item # <strong>LPA</strong> Question Expectations Y/N Corrective Action & Timing<br />

9<br />

10<br />

11<br />

• SHIFT DOWN / START OF PRODUCTION<br />

All questions are to be answered with a "Y" for yes (acceptable or compliant), or<br />

"N" for no (unacceptable or non-compliant) in the status box.<br />

Non-compliances are to have corrective action with timing recorded in the space<br />

Assumptions for using this document:<br />

- Intent of these questions is that the operator is performing a new operation.<br />

- Normal <strong>LPA</strong> is being followed.<br />

- On-going manufacturing process remains in place.<br />

MAINTENANCE ACTIVITIES<br />

Have maintenance activities<br />

been continued as scheduled?<br />

Are maintenance Set-Up parts<br />

controlled and segregated? Are<br />

parts identified / labeled? Is<br />

there a designated location for<br />

maintenance parts? Is there a<br />

process to confirm the quality<br />

of parts produced during<br />

maintenance or set-up activity<br />

(e.g. First Pi<br />

Have all maintenance/setup<br />

parts been purged from Work<br />

Cell areas? Have questionable<br />

parts produced during<br />

maintenance efforts been<br />

quarantined?<br />

Maintenance schedule must be<br />

maintained.<br />

Set-up parts, boundary samples,<br />

etc. must be controlled to avoid<br />

mixing with production parts.<br />

Set-up parts, boundary samples,<br />

etc. must be controlled to avoid<br />

mixing with production parts.<br />

61