HOli.. - Memorial University's Digital Archives - Memorial University ...

HOli.. - Memorial University's Digital Archives - Memorial University ...

HOli.. - Memorial University's Digital Archives - Memorial University ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

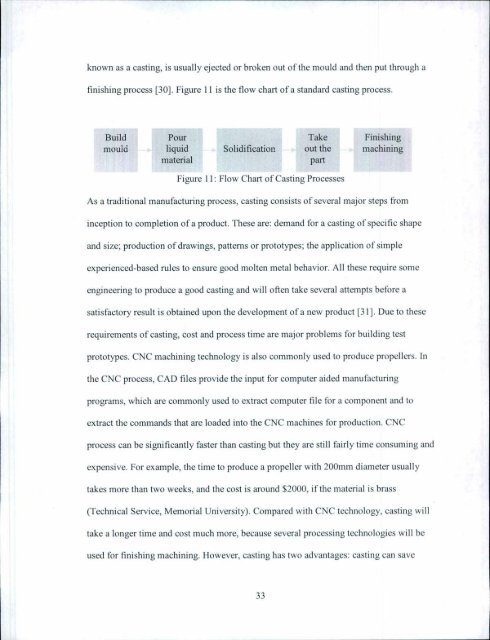

known as a casting, is usually ejected or broken out ofthe mould and then put through a<br />

finishing process [30]. Figure II is the flow chart ofa standard casting process.<br />

Build<br />

mould<br />

Pour<br />

liquid<br />

material<br />

Solidification<br />

Take<br />

out the<br />

part<br />

Fi!,'Ure II: Flow Chart of Casting Processes<br />

Finishing<br />

machining<br />

As a traditional manufacturing process, casting consists of several major steps from<br />

inception to completion ofa product. These are: demand for a casting of specific shape<br />

and size; production ofdrawings, patterns or prototypes; the application ofsimple<br />

experienced-based rules to ensure good molten metal behavior. All these require some<br />

engineering to produce a good casting and will often take several attempts before a<br />

satisfactory result is obtained upon the development of a new product [31]. Due to these<br />

requirements ofcasting, cost and process time are major problems for building test<br />

prototypes. CNC machining technology is also commonly used to produce propellers. In<br />

the CNC process, CAD files provide the input for computer aided manufacturing<br />

programs, which are commonly used to extract computer filc for a component and to<br />

extract the commands that are loaded into the CNC machines for production. CNC<br />

process can be significantly faster than casting but they are still fairly time consuming and<br />

expensive. For example, the time to produce a propeller with 200mm diameter usually<br />

takes more than two weeks, and the cost is around $2000, ifthe material is brass<br />

(Technical Service, <strong>Memorial</strong> <strong>University</strong>). Compared with CNC technology, casting will<br />

take a longer time and cost much morc, because several processing technologies will be<br />

used for finishing machining. However, casting has two advantages: casting can save<br />

J3