SKF Reliability Systems - Library

SKF Reliability Systems - Library

SKF Reliability Systems - Library

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A RISK-BASED APPROACH TO PREVENTIVE<br />

MAINTENANCE REVIEWS AT SYDNEY WATER<br />

This paper describes a practical risk based approach to the Preventive Maintenance (PM) reviews and its<br />

implementation in the computerised maintenance management system in Sydney Water (SWC). It discusses<br />

the triggers for a PM review process at any specific plant or facility. This includes: Changes in operational<br />

parameters impacting on the criticality of specific assets to the process, Measured lack of effectiveness of<br />

current PM program, Identified PM job duplications or over-servicing issues, Increasing cost of failures &<br />

increasing failure rates, Analysis of existing maintenance regime for appropriateness, Procurement of additional<br />

assets / processes / systems or plants, Evidence of not enough PM’s carried out on critical assets.<br />

This review process adopts a practical approach in documenting and addressing the business of operation<br />

and maintenance, risk management, potential changes / modification and failure modes based on a joint<br />

exercise between operations & maintenance. The changes / modifications to the Preventive Maintenance<br />

schedules are then implemented in the Computerised Maintenance Management System (CMMS), which is<br />

then available to Maintenance Delivery to carry out planned maintenance activities across mech/elec operating<br />

assets within SWC. This approach ensures that more reliable assets are available to Sydney Water’s business<br />

at an affordable cost.<br />

SWC’S BACKGROUND<br />

Sydney Water supplies more than 1.4 billion litres of water to more than 1.7 million homes and businesses<br />

each day. About 80 per cent of our supply comes from the Warragamba Dam. We treat the water at 9 water<br />

filtration plants and the largest plant at Prospect treats more than 80 per cent of our water. We then distribute<br />

the water to our customers via our network of 266 service reservoirs, 148 pumping stations and nearly 21,000<br />

kilometres of water mains.<br />

Sydney Water collects and treats more than 1.2 billion litres of wastewater from homes and businesses each<br />

day. Of this, we recycle more than 36 million litres each day. Our sewerage network services around 1.6 million<br />

homes and businesses in the Greater Sydney region. Around 75 per cent of our wastewater is processed at<br />

our three biggest plants at Malabar, North<br />

Head and Bondi.<br />

Sydney Water has a number of water<br />

recycling schemes in place that help<br />

reduce discharges of treated wastewater<br />

to the environment and reduce demand on<br />

water supplies. Use of recycled water is<br />

approximately 25 billion litres a year. This is<br />

expected to grow to 70 billion litres a year<br />

by 2015.<br />

Sydney Water provides stormwater services<br />

to over 1.1 million people, servicing more<br />

than 474,000 properties and 443 kilometres<br />

of stormwater drains, which serve around<br />

25% of metropolitan Sydney.<br />

INTRODUCTION<br />

G Orgil & N Marathe Sydney Water (Australia)<br />

(A Paper Presented at ICOMS Asset Management Conference, Sydney 2009)<br />

Where there is a desire to optimise<br />

Preventive Maintenance (PM) for assets at a<br />

plant or facility and where a comprehensive<br />

Preventive Maintenance review cannot<br />

be justified due to the resource intensive<br />

nature of such an approach, a risk based<br />

review of PM schedules may be used as<br />

an alternative cost effective solution to<br />

solve an immediate problem with a PM<br />

Program. Sydney Water uses a systematic<br />

combination of detailed maintenance<br />

reviews and root-cause analysis to review<br />

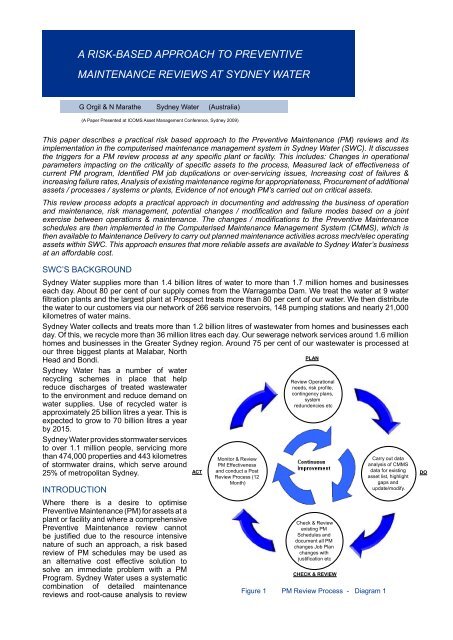

ACT<br />

Monitor & Review<br />

PM Effectiveness<br />

and conduct a Post<br />

Review Process (12<br />

Month)<br />

PLAN<br />

Review Operational<br />

needs, risk profile,<br />

contingency plans,<br />

system<br />

redundencies etc<br />

Check & Review<br />

existing PM<br />

Schedules and<br />

document all PM<br />

changes Job Plan<br />

changes with<br />

justification etc<br />

CHECK & REVIEW<br />

Figure 1 PM Review Process - Diagram 1<br />

Carry out data<br />

analysis of CMMS<br />

data for existing<br />

asset list, highlight<br />

gaps and<br />

update/modify.<br />

DO