SKF Reliability Systems - Library

SKF Reliability Systems - Library

SKF Reliability Systems - Library

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PM Reviews at Sydney Water<br />

available in the following areas:<br />

• PM’s that can be easily rolled up or eliminated/substituted or reduced/optimised based on current<br />

maintenance policy<br />

• Changes in Maintenance standards for different asset classes, including legislated requirements<br />

• Availability of enough redundancies/standbys • Negligible impact of failures on the process or system<br />

• Decommissioned assets or assets not required to be maintained<br />

• Changed circumstances in the operating process or the addition of new assets<br />

DOCUMENTATION OF RISK REVIEW PROCESS<br />

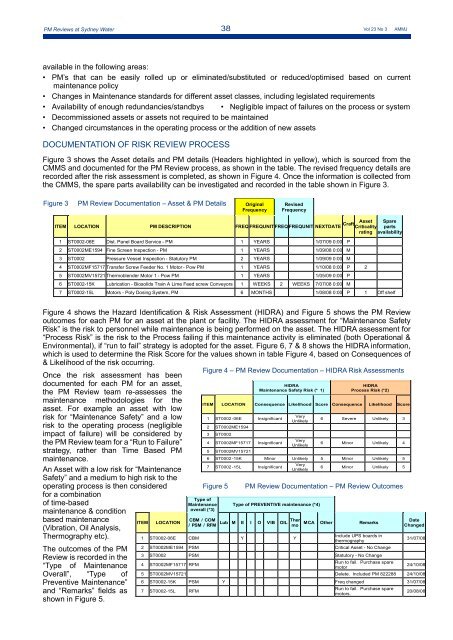

Figure 3 shows the Asset details and PM details (Headers highlighted in yellow), which is sourced from the<br />

CMMS and documented for the PM Review process, as shown in the table. The revised frequency details are<br />

recorded after the risk assessment is completed, as shown in Figure 4. Once the information is collected from<br />

the CMMS, the spare parts availability can be investigated and recorded in the table shown in Figure 3.<br />

Figure 3 PM Review Documentation – Asset & PM Details<br />

Figure 4 shows the Hazard Identification & Risk Assessment (HIDRA) and Figure 5 shows the PM Review<br />

outcomes for each PM for an asset at the plant or facility. The HIDRA assessment for “Maintenance Safety<br />

Risk” is the risk to personnel while maintenance is being performed on the asset. The HIDRA assessment for<br />

“Process Risk” is the risk to the Process failing if this maintenance activity is eliminated (both Operational &<br />

Environmental), if “run to fail” strategy is adopted for the asset. Figure 6, 7 & 8 shows the HIDRA information,<br />

which is used to determine the Risk Score for the values shown in table Figure 4, based on Consequences of<br />

& Likelihood of the risk occurring.<br />

Once the risk assessment has been<br />

documented for each PM for an asset,<br />

the PM Review team re-assesses the<br />

maintenance methodologies for the<br />

asset. For example an asset with low<br />

risk for “Maintenance Safety” and a low<br />

risk to the operating process (negligible<br />

impact of failure) will be considered by<br />

the PM Review team for a “Run to Failure”<br />

strategy, rather than Time Based PM<br />

maintenance.<br />

An Asset with a low risk for “Maintenance<br />

Safety” and a medium to high risk to the<br />

operating process is then considered<br />

for a combination<br />

of time-based<br />

maintenance & condition<br />

based maintenance<br />

ITEM LOCATION<br />

(Vibration, Oil Analysis,<br />

Thermography etc).<br />

The outcomes of the PM<br />

Review is recorded in the<br />

“Type of Maintenance<br />

Overall”, “Type of<br />

Preventive Maintenance”<br />

and “Remarks” fields as<br />

shown in Figure 5.<br />

38 Vol 23 No 3 AMMJ<br />

Original<br />

Frequency<br />

Revised<br />

Frequency<br />

ITEM LOCATION PM DESCRIPTION<br />

Asset<br />

Craft<br />

FREQ FREQUNIT FREQ FREQUNIT NEXTDATE Criticality<br />

rating<br />

Spare<br />

parts<br />

availability<br />

1 ST0002-06E Dist. Panel Board Service - PM 1 YEARS 1/07/09 0:00 P<br />

2 ST0002ME1594 Fine Screen Inspection - PM 1 YEARS 1/09/08 0:00 M<br />

3 ST0002 Pressure Vessel Inspection - Statutory PM 2 YEARS 1/09/09 0:00 M<br />

4 ST0002MF15717 Transfer Screw Feeder No. 1 Motor - Pow PM 1 YEARS 1/10/08 0:00 P 2<br />

5 ST0002MV15721 Thermoblender Motor 1 - Pow PM 1 YEARS 1/05/09 0:00 P<br />

6 ST0002-15K Lubrication - Biosolids Train A Lime Feed screw Conveyors 1 WEEKS 2 WEEKS 7/07/08 0:00 M<br />

7 ST0002-15L Motors - Poly Dosing System, PM 6 MONTHS 1/08/08 0:00 P 1 Off shelf<br />

Figure 4 – PM Review Documentation – HIDRA Risk Assessments<br />

HIDRA<br />

Maintenance Safety Risk (* 1)<br />

HIDRA<br />

Process Risk (*2)<br />

ITEM LOCATION Consequence Likelihood Score Consequence Likelihood Score<br />

Type of<br />

Maintenance<br />

overall (*3)<br />

CBM / COM<br />

/ PSM / RFM<br />

1 ST0002 -06E Insignificant<br />

Very<br />

Unlikely<br />

6 Severe Unlikely 3<br />

2 ST0002ME1594<br />

3 ST0002<br />

4 ST0002MF15717 Insignificant<br />

Very<br />

Unlikely<br />

6 Minor Unlikely 4<br />

5 ST0002MV15721<br />

6 ST0002 -15K Minor Unlikely 5 Minor Unlikely 5<br />

7 ST0002 -15L Insignificant<br />

Very<br />

Unlikely<br />

6 Minor Unlikely 5<br />

Figure 5 PM Review Documentation – PM Review Outcomes<br />

Type of PREVENTIVE maintenance (*4)<br />

Lub M E I O VIB OIL Ther<br />

mo<br />

1 ST0002-06E CBM Y Y<br />

MCA Other Remarks<br />

Include UPS boards in<br />

thermography<br />

Date<br />

Changed<br />

31/07/08<br />

2 ST0002ME1594 PSM Critical Asset - No Change<br />

3 ST0002 PSM Statutory - No Change<br />

4 ST0002MF15717 RFM<br />

Run to fail. Purchase spare<br />

motor<br />

24/10/08<br />

5 ST0002MV15721 Delete. Included PM 822288 24/10/08<br />

6 ST0002-15K PSM Y Freq changed 31/07/08<br />

7 ST0002-15L RFM<br />

Run to fail. Purchase spare<br />

motors.<br />

20/08/08