SKF Reliability Systems - Library

SKF Reliability Systems - Library

SKF Reliability Systems - Library

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

An API In Benchmarking Assets<br />

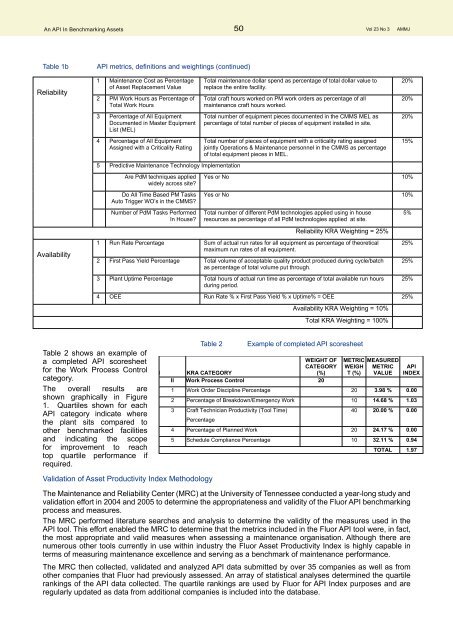

Table 1b API metrics, definitions and weightings (continued)<br />

<strong>Reliability</strong><br />

Availability<br />

1 Maintenance Cost as Percentage<br />

of Asset Replacement Value<br />

2 PM Work Hours as Percentage of<br />

Total Work Hours<br />

3 Percentage of All Equipment<br />

Documented in Master Equipment<br />

List (MEL)<br />

4 Percentage of All Equipment<br />

Assigned with a Criticality Rating<br />

Table 2 shows an example of<br />

a completed API scoresheet<br />

for the Work Process Control<br />

category.<br />

The overall results are<br />

shown graphically in Figure<br />

1. Quartiles shown for each<br />

API category indicate where<br />

the plant sits compared to<br />

other benchmarked facilities<br />

and indicating the scope<br />

for improvement to reach<br />

top quartile performance if<br />

required.<br />

5 Predictive Maintenance Technology Implementation<br />

Are PdM techniques applied<br />

widely across site?<br />

Do All Time Based PM Tasks<br />

Auto Trigger WO’s in the CMMS?<br />

Number of PdM Tasks Performed<br />

In House?<br />

Validation of Asset Productivity Index Methodology<br />

50 Vol 23 No 3 AMMJ<br />

Total maintenance dollar spend as percentage of total dollar value to<br />

replace the entire facility.<br />

Total craft hours worked on PM work orders as percentage of all<br />

maintenance craft hours worked.<br />

Total number of equipment pieces documented in the CMMS MEL as<br />

percentage of total number of pieces of equipment installed in site.<br />

Total number of pieces of equipment with a criticality rating assigned<br />

jointly Operations & Maintenance personnel in the CMMS as percentage<br />

of total equipment pieces in MEL.<br />

The Maintenance and <strong>Reliability</strong> Center (MRC) at the University of Tennessee conducted a year-long study and<br />

validation effort in 2004 and 2005 to determine the appropriateness and validity of the Fluor API benchmarking<br />

process and measures.<br />

The MRC performed literature searches and analysis to determine the validity of the measures used in the<br />

API tool. This effort enabled the MRC to determine that the metrics included in the Fluor API tool were, in fact,<br />

the most appropriate and valid measures when assessing a maintenance organisation. Although there are<br />

numerous other tools currently in use within industry the Fluor Asset Productivity Index is highly capable in<br />

terms of measuring maintenance excellence and serving as a benchmark of maintenance performance.<br />

The MRC then collected, validated and analyzed API data submitted by over 35 companies as well as from<br />

other companies that Fluor had previously assessed. An array of statistical analyses determined the quartile<br />

rankings of the API data collected. The quartile rankings are used by Fluor for API Index purposes and are<br />

regularly updated as data from additional companies is included into the database.<br />

20%<br />

20%<br />

20%<br />

15%<br />

Yes or No 10%<br />

Yes or No 10%<br />

Total number of different PdM technologies applied using in house<br />

resources as percentage of all PdM technologies applied at site.<br />

<strong>Reliability</strong> KRA Weighting = 25%<br />

1 Run Rate Percentage Sum of actual run rates for all equipment as percentage of theoretical<br />

maximum run rates of all equipment.<br />

2 First Pass Yield Percentage Total volume of acceptable quality product produced during cycle/batch<br />

as percentage of total volume put through.<br />

3 Plant Uptime Percentage Total hours of actual run time as percentage of total available run hours<br />

during period.<br />

4 OEE Run Rate % x First Pass Yield % x Uptime% = OEE 25%<br />

Availability KRA Weighting = 10%<br />

Total KRA Weighting = 100%<br />

Table 2 Example of completed API scoresheet<br />

N KRA CATEGORY<br />

WEIGHT OF<br />

CATEGORY<br />

(%)<br />

II Work Process Control 20<br />

METRIC<br />

WEIGH<br />

T (%)<br />

MEASURED<br />

METRIC<br />

VALUE<br />

5%<br />

25%<br />

25%<br />

25%<br />

API<br />

INDEX<br />

1 Work Order Discipline Percentage 20 3.98 % 0.00<br />

2 Percentage of Breakdown/Emergency Work 10 14.68 % 1.03<br />

3 Craft Technician Productivity (Tool Time)<br />

Percentage<br />

40 20.00 % 0.00<br />

4 Percentage of Planned Work 20 24.17 % 0.00<br />

5 Schedule Compliance Percentage 10 32.11 % 0.94<br />

TOTAL 1.97