722.6 TECHNICAL SERVICE INFORMATION

722.6 TECHNICAL SERVICE INFORMATION

722.6 TECHNICAL SERVICE INFORMATION

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

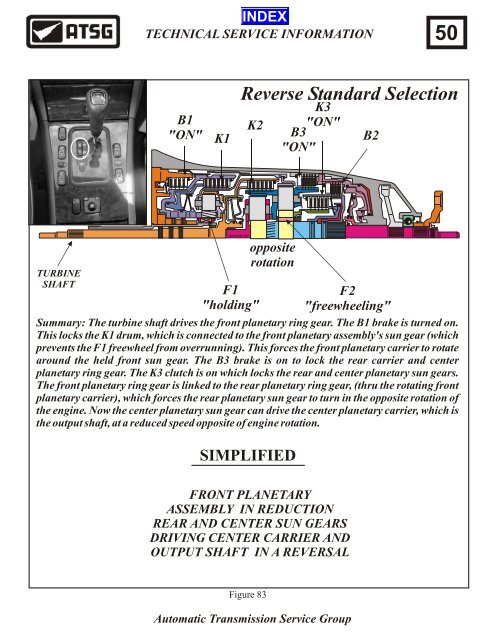

TURBINE<br />

SHAFT<br />

<strong>TECHNICAL</strong> <strong>SERVICE</strong> <strong>INFORMATION</strong><br />

B1<br />

"ON"<br />

K1 K2<br />

F1<br />

"holding"<br />

Figure 83<br />

Automatic Transmission Service Group<br />

50<br />

Reverse Standard Selection<br />

opposite<br />

rotation<br />

K3<br />

"ON"<br />

B3<br />

"ON"<br />

B2<br />

F2<br />

"freewheeling"<br />

Summary: The turbine shaft drives the front planetary ring gear. The B1 brake is turned on.<br />

This locks the K1 drum, which is connected to the front planetary assembly's sun gear (which<br />

prevents the F1 freewheel from overrunning). This forces the front planetary carrier to rotate<br />

around the held front sun gear. The B3 brake is on to lock the rear carrier and center<br />

planetary ring gear. The K3 clutch is on which locks the rear and center planetary sun gears.<br />

The front planetary ring gear is linked to the rear planetary ring gear, (thru the rotating front<br />

planetary carrier), which forces the rear planetary sun gear to turn in the opposite rotation of<br />

the engine. Now the center planetary sun gear can drive the center planetary carrier, which is<br />

the output shaft, at a reduced speed opposite of engine rotation.<br />

SIMPLIFIED<br />

FRONT PLANETARY<br />

ASSEMBLY IN REDUCTION<br />

REAR AND CENTER SUN GEARS<br />

DRIVING CENTER CARRIER AND<br />

OUTPUT SHAFT IN A REVERSAL