World Mineral Production - NERC Open Research Archive - Natural ...

World Mineral Production - NERC Open Research Archive - Natural ...

World Mineral Production - NERC Open Research Archive - Natural ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

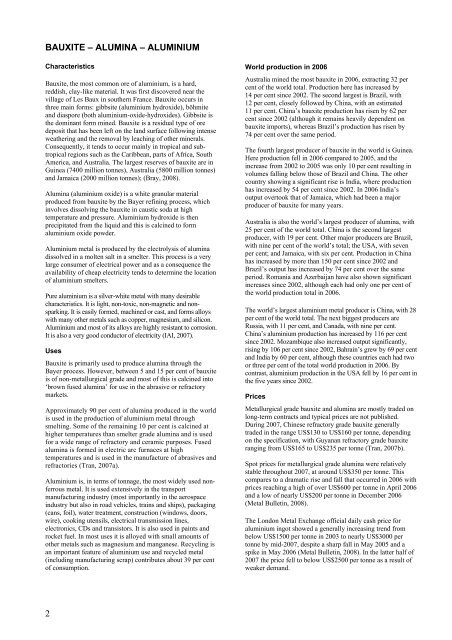

BAUXITE – ALUMINA – ALUMINIUM<br />

Characteristics<br />

Bauxite, the most common ore of aluminium, is a hard,<br />

reddish, clay-like material. It was first discovered near the<br />

village of Les Baux in southern France. Bauxite occurs in<br />

three main forms: gibbsite (aluminium hydroxide), böhmite<br />

and diaspore (both aluminium-oxide-hydroxides). Gibbsite is<br />

the dominant form mined. Bauxite is a residual type of ore<br />

deposit that has been left on the land surface following intense<br />

weathering and the removal by leaching of other minerals.<br />

Consequently, it tends to occur mainly in tropical and subtropical<br />

regions such as the Caribbean, parts of Africa, South<br />

America, and Australia. The largest reserves of bauxite are in<br />

Guinea (7400 million tonnes), Australia (5800 million tonnes)<br />

and Jamaica (2000 million tonnes); (Bray, 2008).<br />

Alumina (aluminium oxide) is a white granular material<br />

produced from bauxite by the Bayer refining process, which<br />

involves dissolving the bauxite in caustic soda at high<br />

temperature and pressure. Aluminium hydroxide is then<br />

precipitated from the liquid and this is calcined to form<br />

aluminium oxide powder.<br />

Aluminium metal is produced by the electrolysis of alumina<br />

dissolved in a molten salt in a smelter. This process is a very<br />

large consumer of electrical power and as a consequence the<br />

availability of cheap electricity tends to determine the location<br />

of aluminium smelters.<br />

Pure aluminium is a silver-white metal with many desirable<br />

characteristics. It is light, non-toxic, non-magnetic and nonsparking.<br />

It is easily formed, machined or cast, and forms alloys<br />

with many other metals such as copper, magnesium, and silicon.<br />

Aluminium and most of its alloys are highly resistant to corrosion.<br />

It is also a very good conductor of electricity (IAI, 2007).<br />

Uses<br />

Bauxite is primarily used to produce alumina through the<br />

Bayer process. However, between 5 and 15 per cent of bauxite<br />

is of non-metallurgical grade and most of this is calcined into<br />

‘brown fused alumina’ for use in the abrasive or refractory<br />

markets.<br />

Approximately 90 per cent of alumina produced in the world<br />

is used in the production of aluminium metal through<br />

smelting. Some of the remaining 10 per cent is calcined at<br />

higher temperatures than smelter grade alumina and is used<br />

for a wide range of refractory and ceramic purposes. Fused<br />

alumina is formed in electric arc furnaces at high<br />

temperatures and is used in the manufacture of abrasives and<br />

refractories (Tran, 2007a).<br />

Aluminium is, in terms of tonnage, the most widely used nonferrous<br />

metal. It is used extensively in the transport<br />

manufacturing industry (most importantly in the aerospace<br />

industry but also in road vehicles, trains and ships), packaging<br />

(cans, foil), water treatment, construction (windows, doors,<br />

wire), cooking utensils, electrical transmission lines,<br />

electronics, CDs and transistors. It is also used in paints and<br />

rocket fuel. In most uses it is alloyed with small amounts of<br />

other metals such as magnesium and manganese. Recycling is<br />

an important feature of aluminium use and recycled metal<br />

(including manufacturing scrap) contributes about 39 per cent<br />

of consumption.<br />

2<br />

<strong>World</strong> production in 2006<br />

Australia mined the most bauxite in 2006, extracting 32 per<br />

cent of the world total. <strong>Production</strong> here has increased by<br />

14 per cent since 2002. The second largest is Brazil, with<br />

12 per cent, closely followed by China, with an estimated<br />

11 per cent. China’s bauxite production has risen by 62 per<br />

cent since 2002 (although it remains heavily dependent on<br />

bauxite imports), whereas Brazil’s production has risen by<br />

74 per cent over the same period.<br />

The fourth largest producer of bauxite in the world is Guinea.<br />

Here production fell in 2006 compared to 2005, and the<br />

increase from 2002 to 2005 was only 10 per cent resulting in<br />

volumes falling below those of Brazil and China. The other<br />

country showing a significant rise is India, where production<br />

has increased by 54 per cent since 2002. In 2006 India’s<br />

output overtook that of Jamaica, which had been a major<br />

producer of bauxite for many years.<br />

Australia is also the world’s largest producer of alumina, with<br />

25 per cent of the world total. China is the second largest<br />

producer, with 19 per cent. Other major producers are Brazil,<br />

with nine per cent of the world’s total; the USA, with seven<br />

per cent; and Jamaica, with six per cent. <strong>Production</strong> in China<br />

has increased by more than 150 per cent since 2002 and<br />

Brazil’s output has increased by 74 per cent over the same<br />

period. Romania and Azerbaijan have also shown significant<br />

increases since 2002, although each had only one per cent of<br />

the world production total in 2006.<br />

The world’s largest aluminium metal producer is China, with 28<br />

per cent of the world total. The next biggest producers are<br />

Russia, with 11 per cent, and Canada, with nine per cent.<br />

China’s aluminium production has increased by 116 per cent<br />

since 2002. Mozambique also increased output significantly,<br />

rising by 106 per cent since 2002, Bahrain’s grew by 69 per cent<br />

and India by 60 per cent, although these countries each had two<br />

or three per cent of the total world production in 2006. By<br />

contrast, aluminium production in the USA fell by 16 per cent in<br />

the five years since 2002.<br />

Prices<br />

Metallurgical grade bauxite and alumina are mostly traded on<br />

long-term contracts and typical prices are not published.<br />

During 2007, Chinese refractory grade bauxite generally<br />

traded in the range US$130 to US$160 per tonne, depending<br />

on the specification, with Guyanan refractory grade bauxite<br />

ranging from US$165 to US$235 per tonne (Tran, 2007b).<br />

Spot prices for metallurgical grade alumina were relatively<br />

stable throughout 2007, at around US$350 per tonne. This<br />

compares to a dramatic rise and fall that occurred in 2006 with<br />

prices reaching a high of over US$600 per tonne in April 2006<br />

and a low of nearly US$200 per tonne in December 2006<br />

(Metal Bulletin, 2008).<br />

The London Metal Exchange official daily cash price for<br />

aluminium ingot showed a generally increasing trend from<br />

below US$1500 per tonne in 2003 to nearly US$3000 per<br />

tonne by mid-2007, despite a sharp fall in May 2005 and a<br />

spike in May 2006 (Metal Bulletin, 2008). In the latter half of<br />

2007 the price fell to below US$2500 per tonne as a result of<br />

weaker demand.