You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

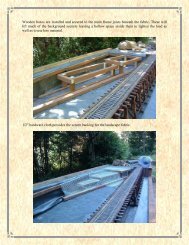

Test fit the trucks. Tighten the mounting screws to just firm, then back off the screws by about<br />

half a turn. Check that the trucks are free to rotate on a short length of test track. There should<br />

only be a very slight side-to-side movement when the car is rocked. Later when the trucks and<br />

the car deck have been painted, the truck mounting screws will be fixed in place with Loctite<br />

222.<br />

Next we will add brake beams and cast brake shoes to our trucks.<br />

Using Hartford Products HP-T001-26 archbar trucks<br />

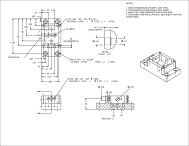

If you want to add brake beam details to<br />

the Hartford Products trucks, I have<br />

successfully modified the trucks to<br />

incorporate this detail. Cut out the four<br />

brake beams from wood, using the<br />

template found on sheet 1. Or use<br />

Hartford Products kit HP-P079 (includes<br />

4 sets of wood beams & brake shoes).<br />

Using a wheel set as a spacing guide,<br />

epoxy the eight brake shoes to the four<br />

brake beams.<br />

Use Ozark or Hartford Products HP-P040<br />

brake shoe castings. Cut four lengths of<br />

K&S 1.13mm (.039”) music wire @ 120mm each. Drill wooden brake beams for music wire<br />

support rods. (32mm centres). Insert wires into one of the end beams, epoxy into place and allow<br />

enough hole length at the outer beam for a small NBW casting. Epoxy two small lengths of brass<br />

or styrene tubing to the under side of the truck centres (32mm spacing). Slide steel wire though<br />

tubes, slide on other brake beam, trim wires to length and secure with epoxy. The wire rods are<br />

not epoxied into the tubes, rather left free to automatically adjust to axle spacing.<br />

Detail brake beams with appropriate NBW castings. Steel music wire is far more ridged than<br />

brass rod and will not droop or bend like brass would tend to do.<br />

Check clearances of brake shoes and<br />

wheels before securing the final brake<br />

beam.