POWER-MASTER 500 - Victor Technologies

POWER-MASTER 500 - Victor Technologies

POWER-MASTER 500 - Victor Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3.01 Location<br />

SECTION 3:<br />

INSTALLATION<br />

Adequate air circulation is needed at all times in order to<br />

assure proper operation. Provide a minimum of 12 inches<br />

(305 mm) of free airspace on all sides of the unit. Make<br />

sure that the ventilator openings are not obstructed. Ventilation<br />

air flow is from rear to side.<br />

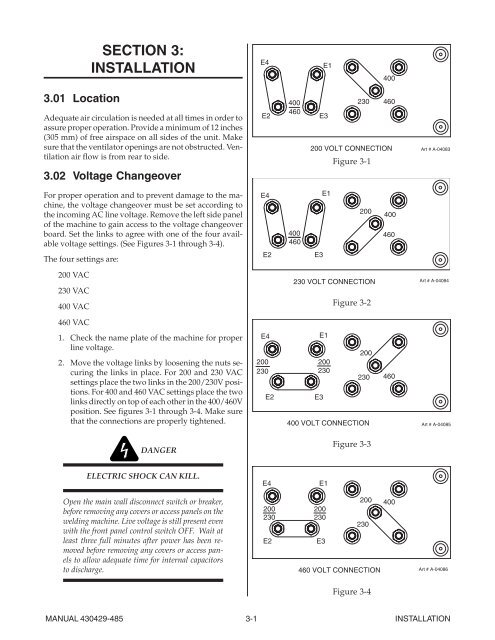

3.02 Voltage Changeover<br />

For proper operation and to prevent damage to the machine,<br />

the voltage changeover must be set according to<br />

the incoming AC line voltage. Remove the left side panel<br />

of the machine to gain access to the voltage changeover<br />

board. Set the links to agree with one of the four available<br />

voltage settings. (See Figures 3-1 through 3-4).<br />

The four settings are:<br />

200 VAC<br />

230 VAC<br />

400 VAC<br />

460 VAC<br />

1. Check the name plate of the machine for proper<br />

line voltage.<br />

2. Move the voltage links by loosening the nuts securing<br />

the links in place. For 200 and 230 VAC<br />

settings place the two links in the 200/230V positions.<br />

For 400 and 460 VAC settings place the two<br />

links directly on top of each other in the 400/460V<br />

position. See figures 3-1 through 3-4. Make sure<br />

that the connections are properly tightened.<br />

DANGER<br />

ELECTRIC SHOCK CAN KILL.<br />

Open the main wall disconnect switch or breaker,<br />

before removing any covers or access panels on the<br />

welding machine. Live voltage is still present even<br />

with the front panel control switch OFF. Wait at<br />

least three full minutes after power has been removed<br />

before removing any covers or access panels<br />

to allow adequate time for internal capacitors<br />

to discharge.<br />

MANUAL 430429-485 3-1 INSTALLATION<br />

E4<br />

E2<br />

E4<br />

400<br />

460<br />

400<br />

460<br />

E2 E3<br />

E4<br />

200<br />

230<br />

E2<br />

E1<br />

E3<br />

400<br />

230 460<br />

200 VOLT CONNECTION<br />

Figure 3-1<br />

E1<br />

200<br />

230 VOLT CONNECTION<br />

200<br />

230<br />

E3<br />

E1<br />

Figure 3-2<br />

400 VOLT CONNECTION<br />

E4 E1<br />

200<br />

230<br />

E2<br />

200<br />

230<br />

E3<br />

200<br />

230<br />

Figure 3-3<br />

230<br />

460 VOLT CONNECTION<br />

Figure 3-4<br />

400<br />

460<br />

460<br />

200 400<br />

Art # A-04083<br />

Art # A-04084<br />

Art # A-04085<br />

Art # A-04086