POWER-MASTER 500 - Victor Technologies

POWER-MASTER 500 - Victor Technologies

POWER-MASTER 500 - Victor Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.03 Connecting Welding Machine<br />

to Line Voltage<br />

The input power should be connected to the unit through<br />

a fused disconnect switch, or other suitable disconnecting<br />

means furnished by the user. Access is provided in<br />

the rear panel of the machine for the entry of the input<br />

conductors.<br />

DANGER:<br />

ELECTRIC SHOCK CAN KILL.<br />

Open the disconnect switch, or breaker, and determine<br />

that no voltage is present, before connecting<br />

wires between welding machine and power supply.<br />

CAUTION:<br />

The method of installation, conductor size, and<br />

overcurrent protection shall conform to the requirements<br />

of the local electrical code, the National Electrical<br />

Code, or other national codes, as applicable.<br />

All installation wiring and machine reconnection<br />

shall be done by qualified persons.<br />

Table 3-1 provides minimal information for selection of<br />

line conductors, fuses, and the equipment grounding conductor.<br />

This information is from the National Electrical<br />

Code NFPA 70-1981 Edition. Install this equipment per<br />

the latest edition, available from the National Fire Protection<br />

Association, Batterymarch Park, Quincy, MA<br />

02269.<br />

Line<br />

Volts<br />

Rated Line<br />

Amps<br />

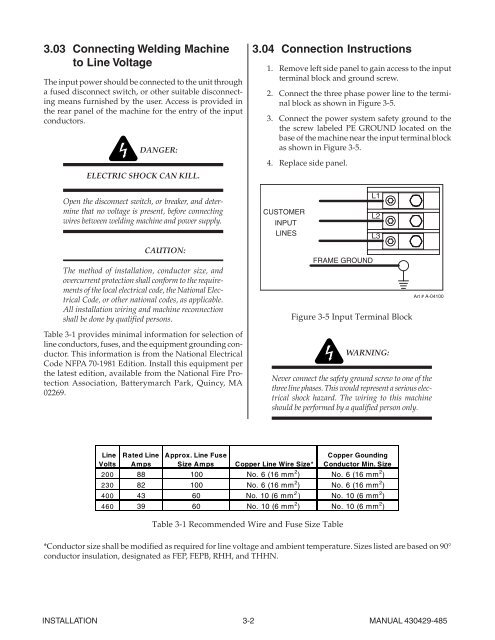

3.04 Connection Instructions<br />

1. Remove left side panel to gain access to the input<br />

terminal block and ground screw.<br />

2. Connect the three phase power line to the terminal<br />

block as shown in Figure 3-5.<br />

3. Connect the power system safety ground to the<br />

the screw labeled PE GROUND located on the<br />

base of the machine near the input terminal block<br />

as shown in Figure 3-5.<br />

4. Replace side panel.<br />

CUSTOMER<br />

INPUT<br />

LINES<br />

Approx. Line Fuse<br />

Size Amps Copper Line Wire Size*<br />

FRAME GROUND<br />

INSTALLATION 3-2 MANUAL 430429-485<br />

L1<br />

L2<br />

L3<br />

Figure 3-5 Input Terminal Block<br />

WARNING:<br />

Art # A-04100<br />

Never connect the safety ground screw to one of the<br />

three line phases. This would represent a serious electrical<br />

shock hazard. The wiring to this machine<br />

should be performed by a qualified person only.<br />

Copper Gounding<br />

Conductor Min. Size<br />

200 88 100 No. 6 (16 mm 2 ) No. 6 (16 mm 2 )<br />

230 82 100 No. 6 (16 mm 2 ) No. 6 (16 mm 2 )<br />

400 43 60 No. 10 (6 mm 2 ) No. 10 (6 mm 2 )<br />

460 39 60 No. 10 (6 mm 2 ) No. 10 (6 mm 2 )<br />

Table 3-1 Recommended Wire and Fuse Size Table<br />

*Conductor size shall be modified as required for line voltage and ambient temperature. Sizes listed are based on 90°<br />

conductor insulation, designated as FEP, FEPB, RHH, and THHN.